Bridge-type CMMs are named for their bridge- or gate-like appearance when viewed from the front. They are known for their high accuracy and stable measurements, making them suitable for inspecting and measuring medical instruments, gears, lenses, and other optical components.

Here, we introduce various bridge-type CMMs offered by different manufacturers. If you're considering implementing a bridge-type CMM, this will be an excellent resource to explore your options.

The CRYSTA-Apex, developed by Mitutoyo, is a versatile CNC CMM designed to meet the demanding requirements of the market. It combines decades of expertise in 3D measurement technology with new advancements to provide high-speed, high-accuracy measurements at an affordable price, even for complex-shaped workpieces.

It tolerates deviations between the workpiece and design values, allowing for high-speed measurements unaffected by machining precision or setup errors. This makes it particularly suitable for complex shapes like turbines, blades, and impellers, where traditional measurements have been challenging.

Equipped with a temperature correction feature and sensors, CRYSTA-Apex ensures accuracy within a temperature range of 16–26°C. It guarantees a maximum permissible length measurement error of 1 E0, MPE=(1.7+3L/1000)μm, ensuring high precision in measurements.

A notable feature is its ability to follow specified measurement paths, controlling the ideal trajectory at high speeds and correcting any errors due to acceleration and deceleration. This enables fast and precise measurements. It also allows for the specification of 3D measurement paths, enabling free-form measurement of complex surfaces and contours.

CRYSTA-Apex comes in two types with different measuring ranges and is compatible with various probes, including scanning and non-contact probes, making it suitable for a wide range of applications. This machine overcomes the challenges and constraints of 3D measurement environments, offering high-quality measurements.

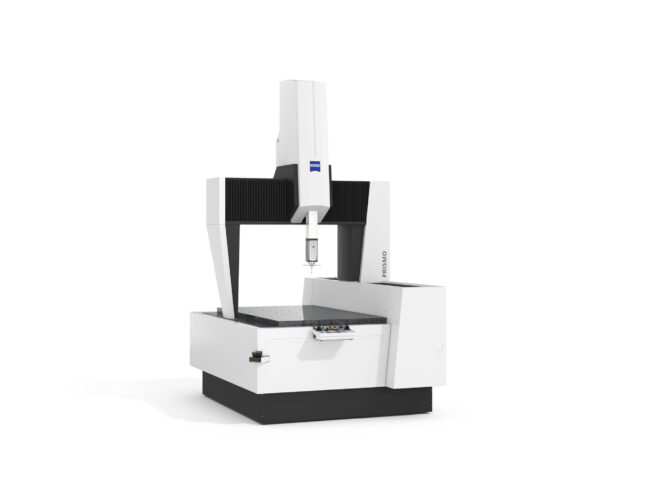

ZEISS PRISMO, the flagship model of ZEISS's CMMs, is an advanced CMM capable of fast and high-accuracy measurements. It is equipped with the precision active scanning sensor 'VAST XT gold', which minimizes deflection during high-speed scanning while maintaining consistent measuring force, thus achieving high accuracy.

This model employs unique technology that supports each axis guide with air bearings, reducing torsion during operation. This ensures stable and high-speed movement, facilitating precise and efficient measurements. It is also designed to withstand temperature fluctuations, maintaining high accuracy in a broad temperature range of 15–30°C.

A notable feature is its 'mass technology', which allows the use of various measuring sensors. Because of this, the ZEISS PRISMO caters to a wide range of measurement needs, both contact and non-contact. For instance, 'VAST gold' enables high-precision active scanning measurements, while options like the 'LineScan2 line laser sensor' and 'DotScan white light distance sensor' are also available.

ZEISS PRISMO is a professional CMM that balances reliability and efficiency, adept at handling challenging parts and complex shapes.

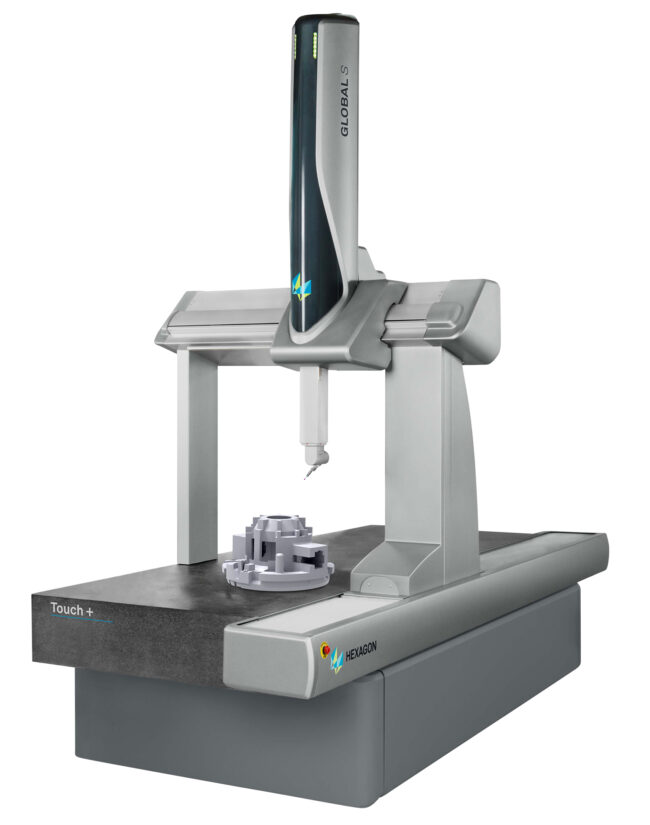

The GLOBAL Touch+ is a CMM that features an electric index probe head and utilizes a six-direction touch trigger probe, offering high versatility and exceptional single-point tactile measurement performance. It guarantees high-precision measurements and cost-effectiveness for complex 3D part shapes.

The structure of GLOBAL Touch+ includes an integrated six-direction touch trigger probe in the automatic probe head, enabling highly reproducible 3D point measurements on various sides of a workpiece. Its flexible probe module exchange rack allows for quick changes between probe modules with different trigger forces and stylus configurations without the need for recalibration, rationalizing the measurement cycle.

This model leverages PC-DMIS CAD, integrating it to inspect parts using CAD models. Additionally, PC-DMIS CAD++ is also available as an option, enabling the measurement of complex parts. The functionalities can be customized to suit specific applications, with options like XT (Extended Temperature) and Eco Mode+ available.

With these features, GLOBAL Touch+ achieves reliable and high-accuracy measurements of various parts and products, including plastic molding parts, mechanical components, and hinge joints.

The Leitz Infinity, developed by Hexagon Metrology, employs a closed-frame design and uses high-resolution scales to achieve uncompromising precision in measurements. It has a measurement range of 1200mm x 1000mm x 700mm, providing a high spatial accuracy of E=0.3+L/1000[μm].

A standout feature of the Leitz Infinity is its extraordinarily accurate probing, particularly suitable for gear measurements. It can measure gears up to a maximum diameter of 950mm, making it ideal for inspecting complex shapes like square parts, cylindrical gears, and globoid worm gears with high precision.

Additionally, Leitz Infinity offers flexibility, allowing the use of long styli and LowForce triggering for measuring delicate surfaces. It can measure lens surfaces and contours when equipped with a Leitz Precitec LR Optical WhiteLight Sensor. Deep sections of parts can also be measured with an 800mm lateral extension probe and the continuous high-speed probe head LSP-S4.

Leitz Infinity, with its high-precision measurements, provides accurate data, helping to reduce manufacturing costs and enhance production efficiency in various fields such as automotive, aerospace, and industrial machinery manufacturing.

Source: KEYENCE Website(https://www.keyence.com/products/measure-sys/cmm/xm/index_pr.jsp)

This CMM has a caliper-like feel, enabling even beginners to perform high-precision measurements. It can be carried without the need for temperature control, allowing for immediate measurements at any desired location and time. As it doesn't require a large installation space, it's a CMM with a low entry barrier.

Source: Carl Zeiss Website(https://www.zeiss.com/metrology/products/systems/cmm.html)

Utilizing linear drive on all axes, this CMM boasts high precision with a maximum permissible length measurement error of 0.3+L/1000μm, repeatability of ±0.2μm, and resolution of 0.001μm. The reduced occurrence of errors allows for a decrease in the need for remeasurement.

Source: Mitutoyo Website(https://www.mitutoyo.com/products/coordinate-measuring-machines/)

A CNC CMM that was first developed in 1976.

It features applications that respond to the demand for "Smart Factories" by allowing monitoring of operational status and maintenance management of the machine through the network.

Reasons for Selection