Coordinate Measuring Machines (CMMs) play a vital role in ensuring dimensional accuracy and repeatability in modern manufacturing. Among the many CMM providers worldwide, Hexagon and Wenzel stand out due to their innovation, performance, and legacy in precision engineering. This article provides a detailed comparison of these two brands, focusing on their technological characteristics, use cases, and design philosophies without prioritizing one over the other.

Hexagon is a global powerhouse in metrology technology, offering a comprehensive range of CMMs including bridge, gantry, and horizontal-arm models. These machines are optimized for integration in diverse industrial environments and come with robust multi-sensor capabilities. Hexagon systems support tactile, optical, and laser sensors, providing excellent flexibility in part inspection.

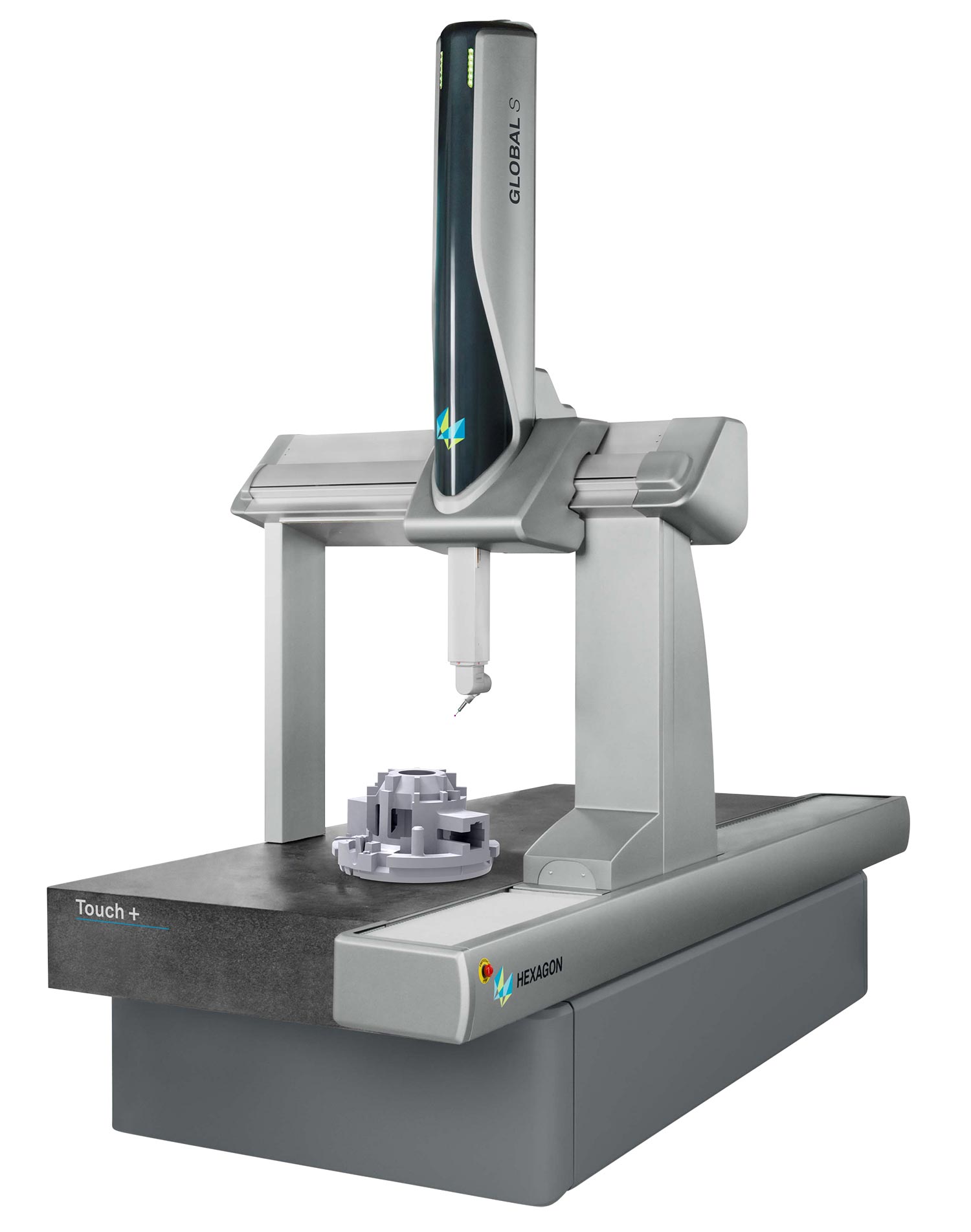

One of the most praised features of Hexagon CMMs is the PC-DMIS software. It offers intuitive CAD model integration, programmable inspection paths, and real-time data output. In addition, newer models like GLOBAL Touch+ feature ergonomic designs with touchscreens and simplified workflows, enabling both high throughput and ease of use.

Two representative models from Hexagon:

| Model | Measurement Range | Accuracy | Special Features |

|---|---|---|---|

| ALPHA | Various sizes (e.g., 1200 x 1500 x 1000 mm) | As low as ±1.5 μm | High-accuracy bridge type, flexible for automation, tactile sensor compatible |

| GLOBAL Touch+ | Varies by configuration | ±2 μm typical | Touch-screen interface, optimized for usability, PC-DMIS integration |

Source: WENZEL website

Source: WENZEL website

(https://en.wenzel-group.com/product-category/cmm-machines)

Wenzel, a German manufacturer with over 50 years of expertise, is renowned for high-precision, robustly built CMMs suitable for a wide array of applications including aerospace, automotive, and heavy machinery. Their systems encompass bridge, gantry, and horizontal-arm models, each tailored to handle specific volumetric and environmental demands.

Wenzel CMMs are built with solid granite structures for maximum thermal stability and mechanical rigidity. The machines support multiple sensor technologies such as tactile probes, optical scanners, and laser systems. Additionally, Wenzel emphasizes modularity and configurability, allowing users to adapt machines to their changing inspection requirements.

Source: WENZEL website

Source: WENZEL website

(https://en.wenzel-group.com/product-category/cmm-machines)

Below are specifications for two representative Wenzel CMM models:

| Model | Measurement Range | Accuracy | Special Features |

|---|---|---|---|

| LH 2015 Gantry | 2,000 mm (X), 3,000/4,000/5,000 mm (Y), 1,500 mm (Z) | ±2.6 + L/450 μm | Granite construction, air bearings, optional active vibration damping |

| RA Series Horizontal Arm | Customizable based on application | Standard and Premium accuracy classes available | Modular design, suitable for large and heavy components, manual or CNC operation |

Hexagon and Wenzel both deliver highly capable CMMs, but their core philosophies and strengths vary significantly. Hexagon focuses on software integration, multi-sensor flexibility, and ease of use in global production environments. In contrast, Wenzel places more emphasis on physical stability, mechanical precision, and customization to specific high-load tasks.

In terms of accuracy, Wenzel's granite-based gantry and horizontal-arm machines are built for high-load and large-scale measurements, making them ideal for automotive chassis or aerospace structures. Hexagon machines, while also accurate, shine in faster workflows, CAD model-based automation, and touchscreen-based control interfaces—perfect for inline inspection or mid-volume manufacturing.

Sensor integration is another differentiation. Hexagon offers broader native support for diverse sensors, while Wenzel allows customized sensor configurations to fit specific use cases. Wenzel’s modular designs enable adaptability to a range of industrial environments and tasks.

Software ecosystems further distinguish them: Hexagon's PC-DMIS is a globally recognized platform optimized for ease of use and scalability, especially for companies operating across borders. Wenzel supports software like WM | Quartis, which offers high configurability and customization for detailed, technical inspection routines.

Lastly, Wenzel's customer service model focuses on precision-driven industries needing tailored support, while Hexagon offers standardized service packages ideal for multinational companies requiring consistent support and training worldwide.

Hexagon is ideal for global manufacturers seeking fast deployment, flexible sensor setups, and user-friendly software interfaces. These machines perform well in automotive, electronics, and medium- to high-volume production scenarios.

Wenzel suits users who require mechanical robustness, high-load capacity, and customization. Industries like aerospace, defense, and heavy equipment manufacturing will benefit from Wenzel’s precision and adaptability to large, heavy components.

Hexagon and Wenzel represent two powerful approaches to dimensional inspection. Hexagon emphasizes adaptability, automation, and global usability, while Wenzel focuses on mechanical precision, configurability, and structural stability. Choosing between the two depends on your industry needs, part size, inspection volume, and regional service expectations. Both brands continue to advance metrology with innovations tailored to the evolving needs of precision manufacturing.