Source: WENZAL website

Source: WENZAL website

(https://en.wenzel-group.com/product-category/cmm-machines)

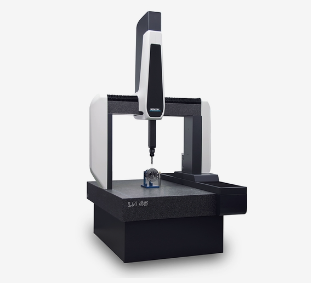

The two series of 3D Gantry CMMs, LH and XO, are characterized by their high precision and dynamic 3D capabilities, making them ideal for small to medium-scale measurement tasks. Each axis of these CMMs features air bearing guides, ensuring smooth motion without abrasion. WENZEL's 3D Gantry CMMs offer a range of designs and equipment options to accommodate customer requirements, providing exceptional product accuracy, long-term stability, reliability, and flexibility.

Source: WENZAL website

Source: WENZAL website

(https://en.wenzel-group.com/product-category/cmm-machines)

Horizontal Arm CMMs are designed for larger workpieces compared to gantry CMMs. The three series available are RA, RS, and RAX. They are particularly well-suited for inspecting plate parts in industries such as automotive, aviation, space, mechanical engineering, and railroads. These CMMs offer the advantage of exceptional flexibility, easy access, and the ability to accommodate a wide range of complex components.

Source: WENZAL website

Source: WENZAL website

(https://en.wenzel-group.com/product-category/cmm-machines)

As the name suggests, Large CMMs boast an enormous measuring range and are suitable for inspecting large and heavy components. Despite their size, they offer the highest accuracy and minimal wear, benefiting from all the advantages of the LH series of 3D Gantry CMMs. Whether it's a large prismatic component or a shaft from the drive of a large engine, these measuring machines can accurately measure and inspect them with pinpoint accuracy.

WENZEL was established in 1968 in Heigenbrücken, Germany, by Werner Wenzel, a master toolmaker with a vision for "precision measuring tools and testing equipment." This vision, along with his passion, was inherited by his daughter, Dr. Heike Wenzel, who currently serves as the group CEO. By the 1970s, WENZEL had already become one of the few manufacturers worldwide capable of supplying components with an accuracy of less than 71 μm. Throughout the 1980s, the company solidified its reputation for providing reliable technology, leading to further expansion. This growth trajectory has persisted to the present day, with WENZEL's subsidiaries and distributors spanning over 50 countries. As a family-owned enterprise, WENZEL has firmly established itself as a leading provider of measurement solutions in the industry.

In addition to providing measuring machines, WENZEL offers an extensive range of metrology software utilized by numerous users across various industries, including automotive, aerospace, mechanical engineering, plastics, and medical technology. These software solutions are utilized for measuring and analyzing parts, with special solutions supporting tasks such as reverse engineering and the analysis of gears and turbine blades. To support the diverse needs of their clients across these industries, WENZEL prioritizes internal quality improvement initiatives. They maintain certifications such as ISO 9001 and VDA 6.4, undergoing continuous audits to ensure the highest standards of their products and processes.

Through the development of metrology software solutions and a commitment to maintaining quality in both products and processes, WENZEL has successfully delivered over 12,000 measurement solutions to a wide range of renowned large and small companies around the world.

One of WENZEL's hallmark features is their commitment to providing timely and reliable support to their customers, both over the phone and online. They have established a hotline to promptly respond to customer inquiries and provide solutions to their problems, irrespective of whether the customer has a contract with WENZEL or has purchased products from them. While many queries can be resolved over the phone, WENZEL also offers WENZEL Online Services (WOS), an Internet-based remote diagnostic and maintenance service.

Furthermore, WENZEL maintains a large central warehouse, ensuring high availability of parts. This enables them to guarantee fast delivery of spare parts, buttons, and accessories, all backed by manufacturer warranties. Through these initiatives, WENZEL has created a customer-friendly support and service infrastructure.

As a leading measurement manufacturer, WENZEL offers cutting-edge solutions with the highest precision in industrial CMMs. Their range includes CMMs equipped with contact and optical sensors, multi-sensor systems, optical high-speed scanning, computed tomography-based 3D X-ray measurement techniques, and more.

Moreover, stemming from their origins as a family-run company, WENZEL places a strong emphasis on close collaboration with their employees and genuine support for their customers. They actively engage with customers to understand and address their challenges, offering tailored solutions in partnership with them.

WENZEL is recommended for those seeking a wide selection of CMM options coupled with steadfast support and collaborative problem-solving.

Source: KEYENCE Website(https://www.keyence.com/products/measure-sys/cmm/xm/index_pr.jsp)

This CMM has a caliper-like feel, enabling even beginners to perform high-precision measurements. It can be carried without the need for temperature control, allowing for immediate measurements at any desired location and time. As it doesn't require a large installation space, it's a CMM with a low entry barrier.

Source: Carl Zeiss Website(https://www.zeiss.com/metrology/products/systems/cmm.html)

Utilizing linear drive on all axes, this CMM boasts high precision with a maximum permissible length measurement error of 0.3+L/1000μm, repeatability of ±0.2μm, and resolution of 0.001μm. The reduced occurrence of errors allows for a decrease in the need for remeasurement.

Source: Mitutoyo Website(https://www.mitutoyo.com/products/coordinate-measuring-machines/)

A CNC CMM that was first developed in 1976.

It features applications that respond to the demand for "Smart Factories" by allowing monitoring of operational status and maintenance management of the machine through the network.

Reasons for Selection