Coordinate Measuring Machines (CMMs) are critical tools in manufacturing, enabling precise and reliable dimensional inspections. Among the top-tier providers, Hexagon and Tokyo Seimitsu each bring unique strengths and technologies to the metrology landscape. This article explores their differences and similarities, without favoring one over the other, to help users determine which system fits their operational needs best.

Hexagon is a globally recognized leader in metrology, offering a diverse lineup of CMMs for complex and demanding inspection tasks. Their machines are known for high-performance bridge, gantry, and horizontal-arm configurations. With robust support for tactile, laser, and optical sensors, Hexagon CMMs excel in multi-sensor integration, allowing streamlined workflows across a wide range of applications.

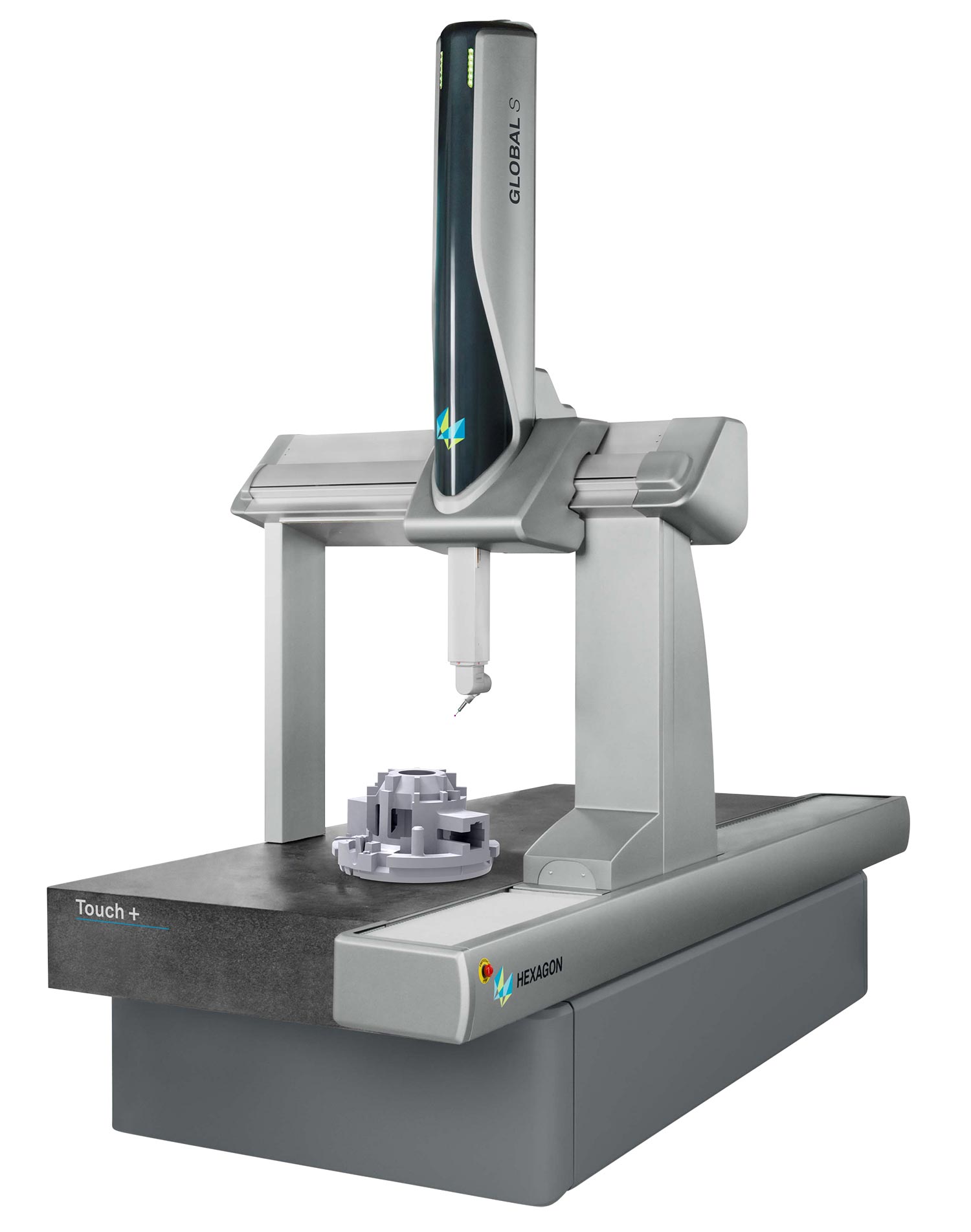

One of Hexagon's strongest offerings is their proprietary PC-DMIS software, which is widely adopted across industries. This platform facilitates CAD-based measurement, automation of inspection routines, and real-time data reporting. The company also emphasizes ergonomic improvements, such as touchscreen interfaces and intuitive user experiences, especially in models like the GLOBAL Touch+.

Two representative models from Hexagon:

| Model | Measurement Range | Accuracy | Special Features |

|---|---|---|---|

| ALPHA | Various sizes (e.g., 1200 x 1500 x 1000 mm) | As low as ±1.5 μm | High-accuracy bridge type, automation-ready, tactile sensor compatible |

| GLOBAL Touch+ | Varies by configuration | ±2 μm typical | Touchscreen UI, CAD integration, PC-DMIS compatibility |

Tokyo Seimitsu, also known under its ACCRETECH brand, has a longstanding partnership with Zeiss, through which it delivers high-precision CMMs tailored to Japanese and Asian industrial needs. These systems are renowned for their structural integrity, environmental adaptability, and advanced automation capabilities.

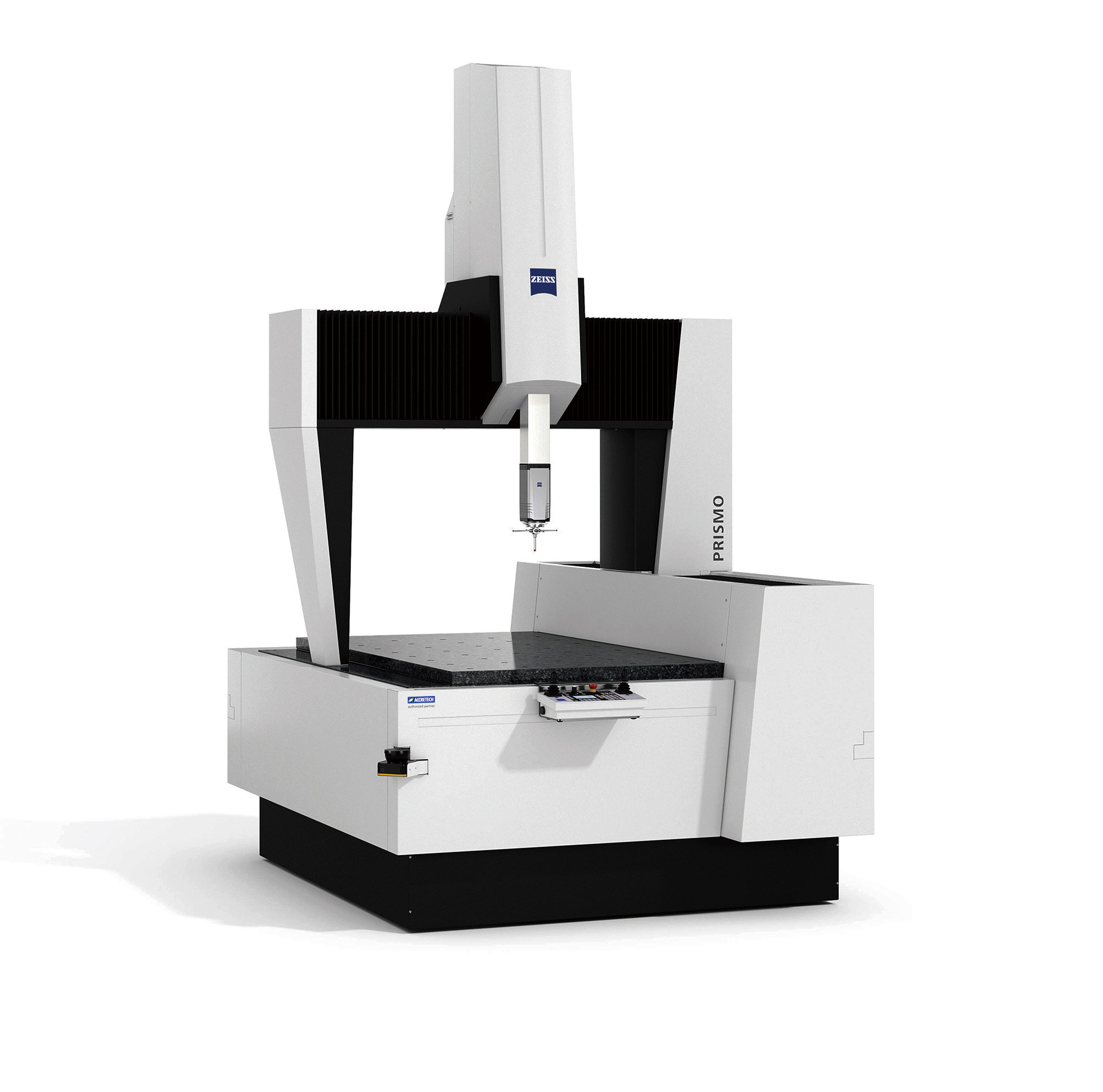

The collaboration integrates Zeiss’s superior sensor technology and CALYPSO software with Tokyo Seimitsu’s engineering precision. This yields machines that are highly accurate, stable under thermal fluctuation, and suited for both laboratory and shop-floor use. Models like the ZEISS XENOS and PRISMO reflect the high-end capabilities of this alliance.

| Model | Measurement Range | Accuracy | Special Features |

|---|---|---|---|

| ZEISS XENOS | 850 x 1200 x 1000 mm | ±0.3 μm | Ultra-high precision, active vibration isolation, air bearings |

| ZEISS PRISMO | 700 mm to 3000 mm (configurable) | ±0.9 μm | Multi-sensor support, thermal compensation, high-speed scanning |

Hexagon and Tokyo Seimitsu both offer advanced and reliable coordinate measuring machines (CMMs), but they cater to different operational needs and market priorities through distinct design philosophies, technical features, and support systems.

In terms of measurement precision, Tokyo Seimitsu—through its long-standing partnership with Zeiss—emphasizes ultra-high accuracy for demanding applications. Models such as the ZEISS XENOS and PRISMO, distributed by Tokyo Seimitsu, are engineered for nanometer-level repeatability and exceptional environmental stability. These machines are ideal for semiconductor, aerospace, and medical component inspection where sub-micron accuracy is non-negotiable. On the other hand, Hexagon delivers high but slightly less extreme precision with models like the ALPHA and GLOBAL Touch+, targeting industries such as automotive, general manufacturing, and electronics where flexibility and throughput are equally critical.

Sensor integration is another point of differentiation. Hexagon offers broad sensor compatibility—including tactile probes, laser scanners, and optical sensors—and excels in integrating these into multi-functional setups. Their user-centric designs often include touch-screen interfaces and real-time data feedback, which enhance productivity on the shop floor. Tokyo Seimitsu CMMs support Zeiss’s sensor ecosystem, including high-speed tactile scanning and precision optical systems. While not as broad in sensor types, the depth of integration with Zeiss technologies ensures consistent and repeatable results, especially for critical dimensions.

Software platforms further highlight each brand’s strategic orientation. Hexagon's PC-DMIS is widely adopted across global industries, known for its powerful automation tools, CAD compatibility, and customizable workflows. It supports both novice and advanced users with scalable features and is ideal for organizations operating across multiple sites or regions. Conversely, Tokyo Seimitsu systems run on Zeiss’s CALYPSO software, which focuses on parametric programming and structured inspection sequences. Though CALYPSO may require more training to master, it provides unmatched stability and traceability in environments where routine verification and audit-readiness are key.

From a structural perspective, Tokyo Seimitsu machines prioritize thermal and vibration isolation. Their granite-based structures and air-bearing systems are built for cleanrooms and metrology labs that demand long-term dimensional stability. Hexagon, by contrast, focuses on ergonomic and production-friendly architecture, with models that can withstand shop-floor conditions without compromising on performance. This makes Hexagon more suitable for inline quality control or environments where measurement speed and accessibility are essential.

One often-overlooked but crucial factor in CMM selection is after-sales support and maintenance. Here, both companies provide robust solutions, though with different emphasis. Hexagon offers globally coordinated support through a network of certified service centers and cloud-based diagnostic tools. Their services include preventive maintenance, remote troubleshooting, on-site calibration, and extensive training programs—ideal for multinational manufacturers seeking standardized service across locations. In contrast, Tokyo Seimitsu delivers highly localized and meticulous support within Japan and parts of Asia. Their service teams are praised for prompt response times, detailed annual maintenance programs, and technical communication in the local language. For companies based in Japan or those prioritizing regional responsiveness, Tokyo Seimitsu offers a significant advantage in service continuity and reliability.

In summary, Hexagon’s strengths lie in its global versatility, wide sensor compatibility, user-friendly software, and scalable service network. Tokyo Seimitsu stands out in precision performance, environmental stability, and deep integration with Zeiss technologies, supported by regionally focused, high-quality service. The optimal choice depends on whether your operation demands maximum flexibility and international scalability, or pinpoint accuracy and tight local support for critical manufacturing environments.

Hexagon CMMs are ideal for manufacturers who require adaptable systems that can handle diverse part geometries and inspection routines. Their broad compatibility with automation and global software makes them a go-to choice for multinational production environments.

Tokyo Seimitsu CMMs are best for companies operating in sectors like aerospace, semiconductor, or medical devices where sub-micron precision, cleanroom compatibility, and stability are paramount. Their machines are designed to meet the strictest requirements for traceable and reproducible measurements.

Hexagon and Tokyo Seimitsu represent two strong pillars of CMM development, each catering to different priorities. Hexagon brings flexibility, global usability, and strong automation tools, while Tokyo Seimitsu provides unmatched precision and environmental control. The right choice depends on your specific measurement demands, part tolerances, and operational environment. Both brands continue to evolve and support the future of high-precision manufacturing.