Coordinate Measuring Machines (CMMs) are essential for ensuring precise dimensional inspection in modern manufacturing. Mitutoyo and Coord 3 are well-known manufacturers offering a range of CMMs tailored for various industrial needs. This article compares their unique strengths and technologies, helping users understand key differences and similarities without prioritizing one over the other.

Mitutoyo, headquartered in Japan, has long been a global leader in precision measurement solutions. Their CMM lineup includes a wide range of models—from compact shop-floor types to high-performance bridge machines for laboratories. Known for reliability, ease of use, and integration flexibility, Mitutoyo CMMs are compatible with contact and non-contact probes.

One of the defining features is the MCOSMOS software platform, which offers modularity, strong CAD integration, and automated inspection routines. This makes Mitutoyo suitable for manufacturers needing scalable solutions across varied production settings. Moreover, their machines feature temperature compensation, robust structures, and efficient probing systems for diverse parts and materials.

| Model | Measurement Range | Accuracy | Special Features |

|---|---|---|---|

| CRYSTA-Plus M | 710 x 1000 x 660 mm | ±1.7 μm | Bridge CMM, MCOSMOS software, multi-sensor compatible |

| MiSTAR 555 | 570 x 500 x 500 mm | ±2.2 μm | Shop-floor CMM, high speed, vibration-resistant, thermal stability |

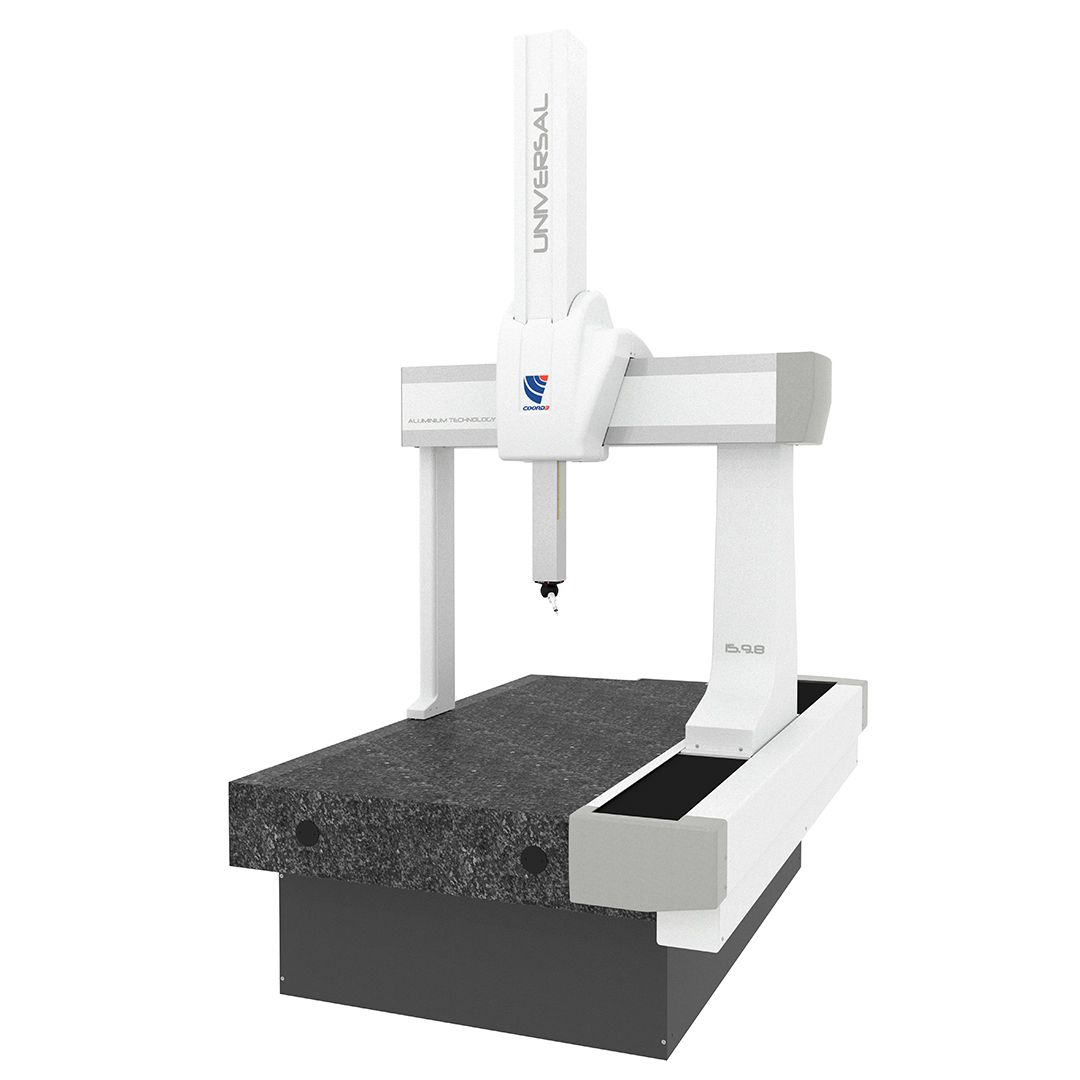

Coord 3, based in Italy, develops robust and adaptable CMMs for a variety of industries including aerospace, automotive, and general manufacturing. Their product line includes bridge, cantilever, and gantry-style machines designed for environments requiring structural strength and flexibility.

Coord 3 systems are compatible with PC-DMIS software, allowing seamless integration with existing inspection infrastructure. These machines also support a range of probing systems, including tactile and optical sensors, enabling high-accuracy measurement of complex parts and geometries.

Their design prioritizes mechanical rigidity, thermal control, and scalability, making Coord 3 CMMs well-suited for environments requiring high consistency and support for large components.

| Model | Measurement Range | Accuracy | Key Features |

|---|---|---|---|

| Ares | 500x500x400mm to 2000x1500x1000mm | Up to ±2μm | Modular design, tactile and optical probe support, thermal compensation |

| MCT PLUS | 3000x2000x1500mm and above | ±2.5μm | Large-volume measurement, gantry structure, suitable for aerospace |

Mitutoyo and Coord 3 approach metrology with distinct philosophies. Mitutoyo emphasizes ease of use, consistent accuracy, and seamless integration into global quality standards, making it an excellent choice for organizations that value reliability and strong support infrastructure. Their machines are designed for both high-precision environments and shop-floor applications, allowing consistent performance under varied operational conditions.

Coord 3, meanwhile, prioritizes mechanical robustness and adaptability to large and complex part measurements. With a focus on structural integrity and thermal stability, Coord 3 systems cater especially well to industries such as aerospace, where oversized and intricate parts are the norm. Their systems are also well-suited for markets requiring scalable CMMs with support for advanced probe technologies and CAD-driven inspection workflows.

In terms of software compatibility, Mitutoyo uses MCOSMOS—a modular and deeply integrated platform, especially beneficial for companies already using Mitutoyo tools. Coord 3, on the other hand, supports PC-DMIS, a widely-used metrology software that many engineers are already familiar with, enhancing flexibility in multi-vendor environments.

While both brands offer support for multi-sensor configurations, Coord 3 stands out for offering gantry and large-format CMMs, whereas Mitutoyo excels in providing temperature-stable, high-speed systems for smaller and mid-sized parts. Ultimately, both manufacturers present reliable choices, but the optimal selection depends on whether the focus is on environmental robustness and size scalability (Coord 3) or software integration and operational familiarity (Mitutoyo).

Mitutoyo CMMs are ideal for manufacturers seeking highly repeatable results in both laboratory and production-floor settings. Their machines are especially useful for small to medium-sized components, and companies that value end-to-end integration with other Mitutoyo instruments. Mitutoyo is also a solid choice for businesses needing a globally recognized brand with strong after-sales support and service coverage. Additionally, its intuitive MCOSMOS software makes it accessible for users who prioritize ease of implementation and scalable measurement operations.

Coord 3 CMMs are best suited for operations that demand large-scale measurement capabilities, particularly in sectors like aerospace, energy, and heavy machinery. Their gantry-style and high-rigidity machines are built to accommodate oversized components with complex geometries. Coord 3 is also advantageous for companies with established use of PC-DMIS or those transitioning from other vendors, due to its open compatibility and robust structural designs. Manufacturers operating in harsh or variable environments can benefit from Coord 3’s thermal resilience and design adaptability.

Mitutoyo and Coord 3 both offer strong and reliable CMM solutions tailored to different operational contexts. Mitutoyo emphasizes precision, consistency, and ease of integration across global facilities, while Coord 3 offers large-format, heavy-duty machines ideal for big part measurement and structural stability. Choosing between them depends on your manufacturing priorities—whether that’s global compatibility and familiar software, or adaptability to oversized, complex geometries.