Coordinate Measuring Machines (CMMs) are indispensable in modern manufacturing for verifying dimensional accuracy and maintaining product quality. Tokyo Seimitsu and FARO represent two highly respected but fundamentally different approaches in the CMM industry. This article explores their technologies, strengths, and ideal use cases without placing one above the other.

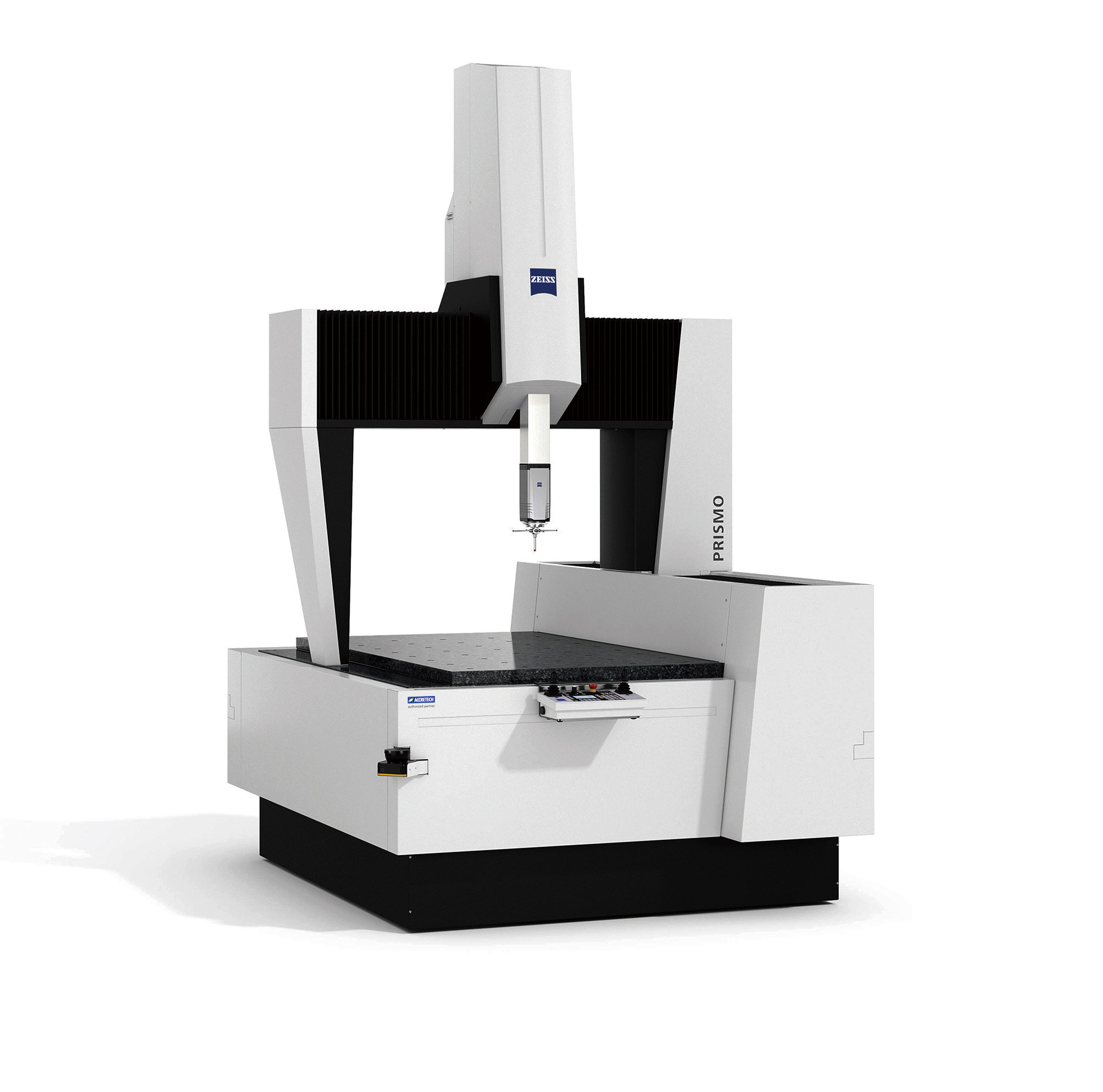

Tokyo Seimitsu, known by the ACCRETECH brand, collaborates closely with Zeiss to provide ultra-precise, fixed CMM systems. These machines are engineered for environments requiring exceptional measurement accuracy and stability, such as semiconductor fabrication, medical device production, and aerospace component manufacturing. Tokyo Seimitsu emphasizes high structural rigidity, temperature control, and vibration mitigation. Their machines are frequently found in climate-controlled laboratories, ensuring long-term dimensional stability and repeatability.

Software plays a central role in Tokyo Seimitsu's CMM ecosystem. The Zeiss CALYPSO platform enables highly customizable and traceable measurement routines. Its parametric programming capabilities make it especially well-suited for regulated industries where audit trails and data integrity are critical.

| Model | Measurement Range | Accuracy | Special Features |

|---|---|---|---|

| ZEISS XENOS | 850 x 1200 x 1000 mm | ±0.3 μm | Ultra-high precision, air bearings, vibration isolation |

| ZEISS PRISMO | 700 mm to 3000 mm (configurable) | ±0.9 μm | High-speed scanning, multi-sensor support, thermal compensation |

FARO is globally known for its portable articulated arm CMMs. These systems offer flexibility and mobility, making them suitable for shop-floor use and in-field inspection. FARO’s devices are engineered for rapid deployment, wireless operation, and intuitive use. The FaroArm series is often employed in industries such as automotive repair, aerospace maintenance, and custom tooling.

FARO's CAM2 software facilitates real-time feedback, feature alignment, and CAD comparison. Their systems support 6- and 7-axis movement, and models like the 8-Axis FaroArm include a rotating platform, allowing full-part access without repositioning.

| Model | Measurement Range | Accuracy | Special Features |

|---|---|---|---|

| Gage Max | 1.2 m working volume | ±0.018 mm | Compact 6-axis arm, wireless, benchtop use |

| FARO ARM 8-Axis | Up to 4 m | ±0.029 mm | Rotating platform, 8-axis motion, ideal for large parts |

Tokyo Seimitsu and FARO cater to fundamentally different use cases, despite both offering precise measurement systems. Tokyo Seimitsu’s CMMs focus on fixed, ultra-accurate inspection in controlled environments, while FARO’s portable arms are designed for fast, flexible deployment.

Accuracy levels represent one major distinction. Tokyo Seimitsu machines, such as the ZEISS XENOS, offer sub-micron precision suitable for applications where even minute deviations can affect product function. By contrast, FARO’s portable arms, while accurate enough for many industrial applications, are not intended for nanometer-scale tolerances.

Mobility and ease of use are where FARO truly shines. Their CMMs require minimal setup and can be transported to inspection sites easily. This is especially advantageous for large assemblies or field work where transporting the part to the lab is impractical. Tokyo Seimitsu machines, on the other hand, require a stable and clean environment, making them ideal for quality assurance labs or production environments with climate control.

Software capabilities differ as well. FARO’s CAM2 enables visual inspections and quick comparisons with CAD models, supporting real-time decision-making. Tokyo Seimitsu's CALYPSO software, by contrast, is tailored to users who require structured routines and detailed reporting, especially in industries with stringent compliance standards.

In terms of sensor integration, Tokyo Seimitsu leverages the precision of Zeiss’s tactile and optical probes, prioritizing quality and consistency. FARO supports a broad range of laser and touch sensors, often focusing on speed, accessibility, and field adaptability. This reflects a broader philosophical difference: Tokyo Seimitsu prioritizes exactness and traceability, while FARO emphasizes accessibility and versatility.

Lastly, infrastructure needs and total cost of ownership differ greatly. Tokyo Seimitsu systems represent a significant investment, both in terms of hardware and facility requirements. FARO’s systems, in contrast, are more affordable and require less space and fewer environmental controls, making them appealing to small and mid-sized manufacturers.

Tokyo Seimitsu is ideal for industries such as aerospace, semiconductors, and medical devices where extremely tight tolerances, traceability, and regulatory compliance are essential. Their CMMs are best suited for quality assurance laboratories and cleanroom environments.

FARO is best for manufacturers needing fast, flexible, and cost-effective measurement solutions. Their systems excel in field inspections, large-part measurement, and reverse engineering workflows, particularly in automotive and general manufacturing.

Tokyo Seimitsu and FARO each offer compelling advantages depending on the measurement context. While Tokyo Seimitsu excels in ultra-precise, lab-grade inspections, FARO enables mobile, user-friendly measurements with sufficient precision for many practical applications. Choosing between them requires assessing your operational needs, infrastructure, and measurement goals. Both brands continue to innovate and serve key roles in advancing global manufacturing quality.