Here, we introduce the lineup and notable features of the CMMs provided by Zeiss, a leading German optical instrument manufacturer. The article also summarizes the company's characteristics, philosophy, and development approach as a manufacturer.

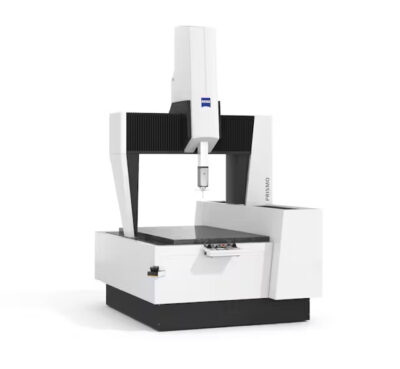

The DuraMax is a CMM that combines precision, efficiency, and robustness. It is highly dust and moisture resistant, achieving thermal stability through the use of glass ceramic scales. It can perform accurate measurements even in harsh environments, and its rotary table allows for 4-axis measurements, reducing operation time.

A dual system that can parallelize the measurement process and the clamping/unclamping of the workpiece increases the machine's operating rate. Moreover, the robust DuraMax HTG type is designed for accurate measurements even in high temperatures, with an expanded temperature range of 3.9+L/100 at 15°C to 40°C.

A representative CMM by Zeiss that balances high precision with high-speed measurement. To cater to various environments, the PRISMO series consists of four models. The ZEISS PRISMO 7/12/7 fortis, equipped with an acceleration mode, is used in the aerospace industry where high precision is required.

Furthermore, performance accelerators are available to enhance speed, flexibility, and productivity. By adding enhancements to desired areas such as scanning speed or single-point measurement speed, production efficiency as required by the site can be achieved.

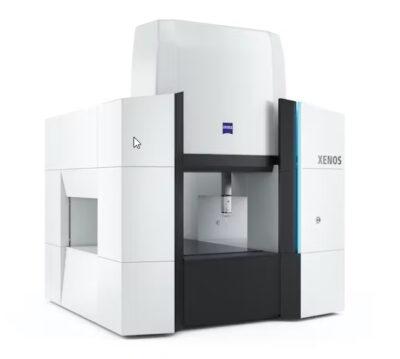

ZEISS XENOS is a high-end model CMM, meeting the demands of research institutions and the optical instrument industry. It has two linear drives in the Y-axis, synchronized through unique technology, functioning as a center drive for optimal driving force depending on the X-axis position.

The machine uses silicon carbide ceramic for its components, which has less thermal expansion and higher rigidity compared to general aluminum oxide ceramics, achieving double the rigidity while halving the weight. Furthermore, the influence of cable movement on accuracy is minimized through distributed modules and circuit improvements.

Zeiss is a leading German optical and precision instrument manufacturer. Founded in 1846 by Zeiss in Jena, the company now has its base in Oberkochen and operates in various fields including eyeglass lenses, camera lenses, binoculars, semiconductors, etc.

Leveraging their experience and know-how, they provide CMMs known for high accuracy, flexibility, expandability, and user-friendliness. They focus on developing CMMs that are adaptable to different site environments.

Zeiss actively engages in new fields like digitalization and healthcare, maintaining a leading role in the industry. The high accuracy of their CMMs is attributed to their focus that goes beyond the consumer market.

While expanding into various fields, the company remains true to its foundation in optics and precision instruments, ensuring a solid and unwavering business approach. This steadfastness is why they are trusted in industries such as aerospace and various research institutions.

The industrial measuring technology division of Zeiss has manufacturing bases in four countries and over 100 sales and service centers globally. All related modules like software and sensors are developed in-house.

Large-scale machines are developed in Germarny, while medium-sized CMM systems and horizontal arm CMMs are managed in China. Their North American locations, are equipped with customer training centers and showrooms, and the softwar for Zeiss products is developed in Italy.

Zeiss’s CMMs, known for their precision and speed, are developed with a focus on addressing on-site challenges. A key feature is their clear understanding of what environment-specific issues need to be resolved.

Their strength lies in the ability to add proprietary developed options when basic functions are insufficient. They are recommended for companies facing challenges in harsh environments where ordinary measuring machines fail or where there is a significant drop in productivity.

Source: KEYENCE Website(https://www.keyence.com/products/measure-sys/cmm/xm/index_pr.jsp)

This CMM has a caliper-like feel, enabling even beginners to perform high-precision measurements. It can be carried without the need for temperature control, allowing for immediate measurements at any desired location and time. As it doesn't require a large installation space, it's a CMM with a low entry barrier.

Source: Carl Zeiss Website(https://www.zeiss.com/metrology/products/systems/cmm.html)

Utilizing linear drive on all axes, this CMM boasts high precision with a maximum permissible length measurement error of 0.3+L/1000μm, repeatability of ±0.2μm, and resolution of 0.001μm. The reduced occurrence of errors allows for a decrease in the need for remeasurement.

Source: Mitutoyo Website(https://www.mitutoyo.com/products/coordinate-measuring-machines/)

A CNC CMM that was first developed in 1976.

It features applications that respond to the demand for "Smart Factories" by allowing monitoring of operational status and maintenance management of the machine through the network.

Reasons for Selection