Coordinate Measuring Machines (CMMs) are indispensable tools in modern manufacturing and quality assurance, used to ensure that parts and components meet exact specifications. Among the diverse landscape of CMM providers, Wenzel and FARO stand out for their unique approaches to metrology. While Wenzel is recognized for its structurally rigid and modular systems, FARO excels in portability and real-time scanning capabilities. This article explores the characteristics, technologies, and ideal applications of both brands, helping users identify which solution aligns best with their measurement requirements.

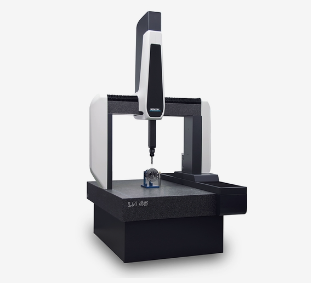

Source: WENZEL website

Source: WENZEL website

(https://en.wenzel-group.com/product-category/cmm-machines)

Wenzel, a German company with over half a century of expertise, has earned its place in the global metrology market by manufacturing CMMs known for mechanical robustness, long-term dimensional stability, and versatility. Unlike some competitors that emphasize proprietary ecosystems, Wenzel focuses on building machines with open compatibility, enabling integration with a variety of sensor types and software platforms. This allows users greater freedom when tailoring their CMM to evolving production requirements.

The company offers bridge-type, gantry-style, and horizontal-arm CMMs, many of which are constructed from natural granite for enhanced thermal stability. Air bearings and active vibration damping systems ensure precise performance even under fluctuating environmental conditions. Wenzel’s solutions can accommodate tactile, laser, and optical sensors, making them suitable for both high-precision inspection tasks and large-scale industrial applications. Furthermore, the modularity of Wenzel’s CMMs enables future upgrades and adaptations, extending the lifespan and value of the investment.

Wenzel's software suite includes WM | Quartis, which is designed for powerful geometric evaluation and seamless CAD interaction. It also supports third-party platforms, providing flexibility for companies with established digital inspection workflows. This dual support model enhances usability for both experienced metrologists and technicians transitioning from other systems.

Source: WENZEL website

Source: WENZEL website

(https://en.wenzel-group.com/product-category/cmm-machines)

Below are specifications for two representative Wenzel CMM models:

| Model | Measurement Range | Accuracy | Special Features |

|---|---|---|---|

| LH 2015 Gantry | 2,000 mm (X), 3,000/4,000/5,000 mm (Y), 1,500 mm (Z) | ±2.6 + L/450 μm | Granite construction, air bearings, optional active vibration damping |

| RA Series Horizontal Arm | Customizable based on application | Standard and Premium accuracy classes available | Modular design, suitable for large and heavy components, manual or CNC operation |

FARO is a globally recognized leader in the field of portable coordinate measuring systems, especially known for its articulated arm CMMs. These systems are engineered for flexibility, speed, and usability, making them ideal for on-site measurements, maintenance operations, and shop-floor inspections where traditional fixed CMMs might not be feasible.

FARO’s flagship offerings include the FaroArm series, which comes in multiple configurations supporting 6- and 7-axis movement. Select models are enhanced with an additional rotating platform (8-axis), enabling full 360-degree access to parts without the need for repositioning. This design significantly streamlines measurement workflows for complex geometries.

FARO’s CAM2 software supports real-time feedback, intuitive probe guidance, CAD model alignment, and automated inspection templates. The systems are suitable for applications such as reverse engineering, rapid prototyping, and quality verification, especially in industries that require speed and agility over fixed-lab infrastructure.

The articulated arms incorporate high-resolution encoders within each joint, delivering accurate spatial tracking and reducing reliance on bulky fixturing. Many of FARO’s CMMs are battery-powered and capable of wireless communication, reinforcing their role in mobile and field-oriented measurement operations.

| Model | Measurement Range | Accuracy | Special Features |

|---|---|---|---|

| Gage Max | 1.2 m working volume | ±0.018 mm | Compact 6-axis arm, wireless, benchtop use |

| FARO ARM 8-Axis | Up to 4 m | ±0.029 mm | Rotating platform, 8-axis motion, ideal for large parts |

Wenzel and FARO each present distinctive strengths in the field of metrology. Wenzel focuses on structural integrity, modular architecture, and fixed installations, while FARO emphasizes flexibility, mobility, and operator-friendly systems. Despite these differences, both brands serve the common purpose of delivering reliable and high-performance measurements across various industries.

In terms of installation and use environments, Wenzel’s systems are ideal for controlled facilities such as quality assurance labs or cleanrooms. Their granite-based construction, vibration isolation, and high rigidity make them suited for long-duration, high-precision measurements. FARO, in contrast, thrives in less predictable environments such as production floors, on-site service areas, and mobile inspection units. The portability and fast setup of FARO arms make them the preferred choice for industries needing quick, actionable insights.

Sensor integration is another important comparison point. While Wenzel supports a broad range of sensor options—tactile, optical, and laser—the systems are generally oriented toward high-stability measurements of heavy or intricate parts. FARO arms also support multiple probing methods but lean more heavily toward real-time 3D scanning, CAD alignment, and digital modeling. This makes FARO particularly strong in reverse engineering and agile manufacturing workflows.

From a software standpoint, Wenzel’s WM | Quartis offers robust geometric analysis and CAD interoperability, while maintaining compatibility with third-party platforms for maximum flexibility. FARO’s CAM2 provides a tightly integrated ecosystem that simplifies workflow creation, real-time inspection, and visual alignment, particularly beneficial to technicians with limited CMM training.

Accuracy specifications also reveal different philosophies. Wenzel’s fixed systems generally offer higher baseline accuracy and repeatability, especially in larger gantry or horizontal-arm formats. FARO’s articulated arms, while slightly less precise in extreme tolerances, are calibrated for high-speed use, sufficient for most medium-precision tasks in manufacturing, maintenance, and prototyping.

In terms of scalability, Wenzel machines can be upgraded and expanded over time thanks to their modular architecture, which is an advantage for facilities expecting growth or diversification. FARO’s systems, being more standardized and compact, excel in scalability across teams or sites, allowing easy deployment in decentralized operations.

In summary, Wenzel stands out in structural durability, measurement stability, and adaptability for high-volume or high-mass part inspection. FARO excels in portable metrology, fast deployment, and user-centric workflows. Each system has its place depending on operational context, mobility needs, and user experience levels.

Wenzel CMMs are best suited for manufacturers who require stationary, ultra-stable systems capable of inspecting large, complex, or temperature-sensitive parts. Their ideal users include aerospace, heavy machinery, and automotive OEMs with centralized QA facilities and experienced metrology teams.

FARO CMMs are ideal for users in need of portable, quick-to-deploy systems that can be operated in diverse environments with minimal setup. FARO serves industries like custom tooling, field service, aerospace MRO (maintenance, repair, and overhaul), and low-volume prototyping with strong demand for CAD-based validation and real-time feedback.

Both Wenzel and FARO have carved out strong reputations in the coordinate metrology market, albeit through very different approaches. Wenzel focuses on precision, rigidity, and long-term adaptability in fixed systems, while FARO leads in portability, ease of use, and agile measurement. Choosing between them depends on your operational needs, whether it’s factory-floor mobility or cleanroom-grade repeatability. Regardless of the choice, both brands offer solutions that enhance inspection efficiency, improve product quality, and support the evolving demands of modern manufacturing.

Source: KEYENCE Website(https://www.keyence.com/products/measure-sys/cmm/xm/index_pr.jsp)

This CMM has a caliper-like feel, enabling even beginners to perform high-precision measurements. It can be carried without the need for temperature control, allowing for immediate measurements at any desired location and time. As it doesn't require a large installation space, it's a CMM with a low entry barrier.

Source: Carl Zeiss Website(https://www.zeiss.com/metrology/products/systems/cmm.html)

Utilizing linear drive on all axes, this CMM boasts high precision with a maximum permissible length measurement error of 0.3+L/1000μm, repeatability of ±0.2μm, and resolution of 0.001μm. The reduced occurrence of errors allows for a decrease in the need for remeasurement.

Source: Mitutoyo Website(https://www.mitutoyo.com/products/coordinate-measuring-machines/)

A CNC CMM that was first developed in 1976.

It features applications that respond to the demand for "Smart Factories" by allowing monitoring of operational status and maintenance management of the machine through the network.

Reasons for Selection