Coordinate Measuring Machines (CMMs) play a vital role in modern manufacturing, ensuring the dimensional integrity of components across various industries. Tokyo Seimitsu and Coord 3 are two highly regarded CMM manufacturers, each offering distinct strengths tailored to specific operational needs. This article presents a detailed comparison of these two brands, exploring their unique features and specifications without favoring one over the other.

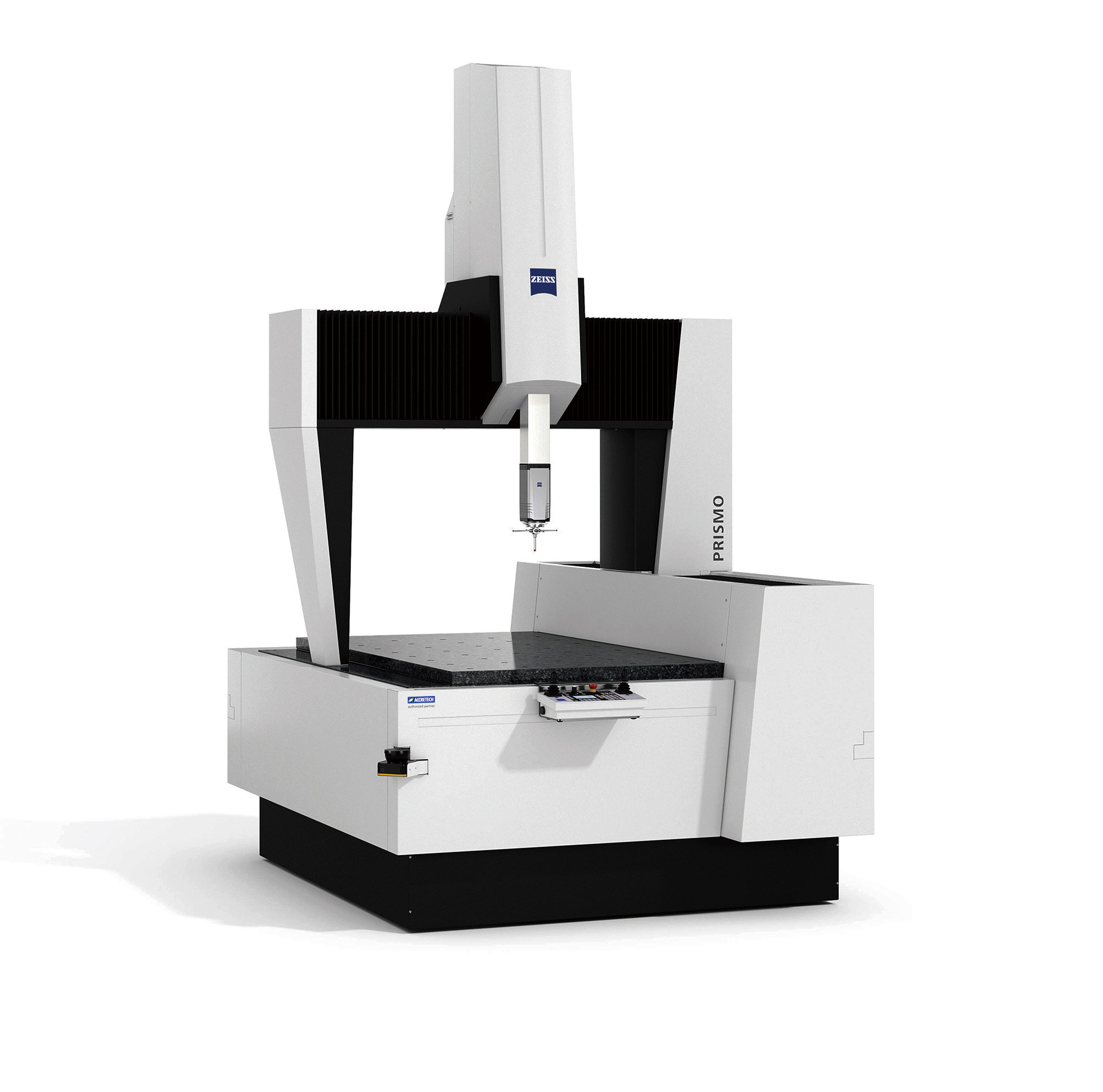

Tokyo Seimitsu, operating under the ACCRETECH brand, is a respected player in the metrology field, especially in Japan and Asia. Through a strategic partnership with Zeiss, Tokyo Seimitsu distributes high-precision CMMs that combine robust mechanical design with state-of-the-art sensor technology. These machines are built for environments that demand ultra-high accuracy, such as semiconductor, aerospace, and medical industries.

Their machines are known for structural rigidity, thermal stability, and compatibility with Zeiss’s CALYPSO software. This software allows for detailed parametric inspection, high-level customization, and powerful data management. Tokyo Seimitsu also emphasizes vibration isolation and cleanroom-ready construction, enabling consistent results even in the most demanding applications.

| Model | Measurement Range | Accuracy | Special Features |

|---|---|---|---|

| ZEISS XENOS | 850 x 1200 x 1000 mm | ±0.3 μm | Ultra-high accuracy, vibration isolation, air bearings |

| ZEISS PRISMO | 700 mm to 3000 mm (configurable) | ±0.9 μm | Multi-sensor compatibility, thermal compensation, high-speed scanning |

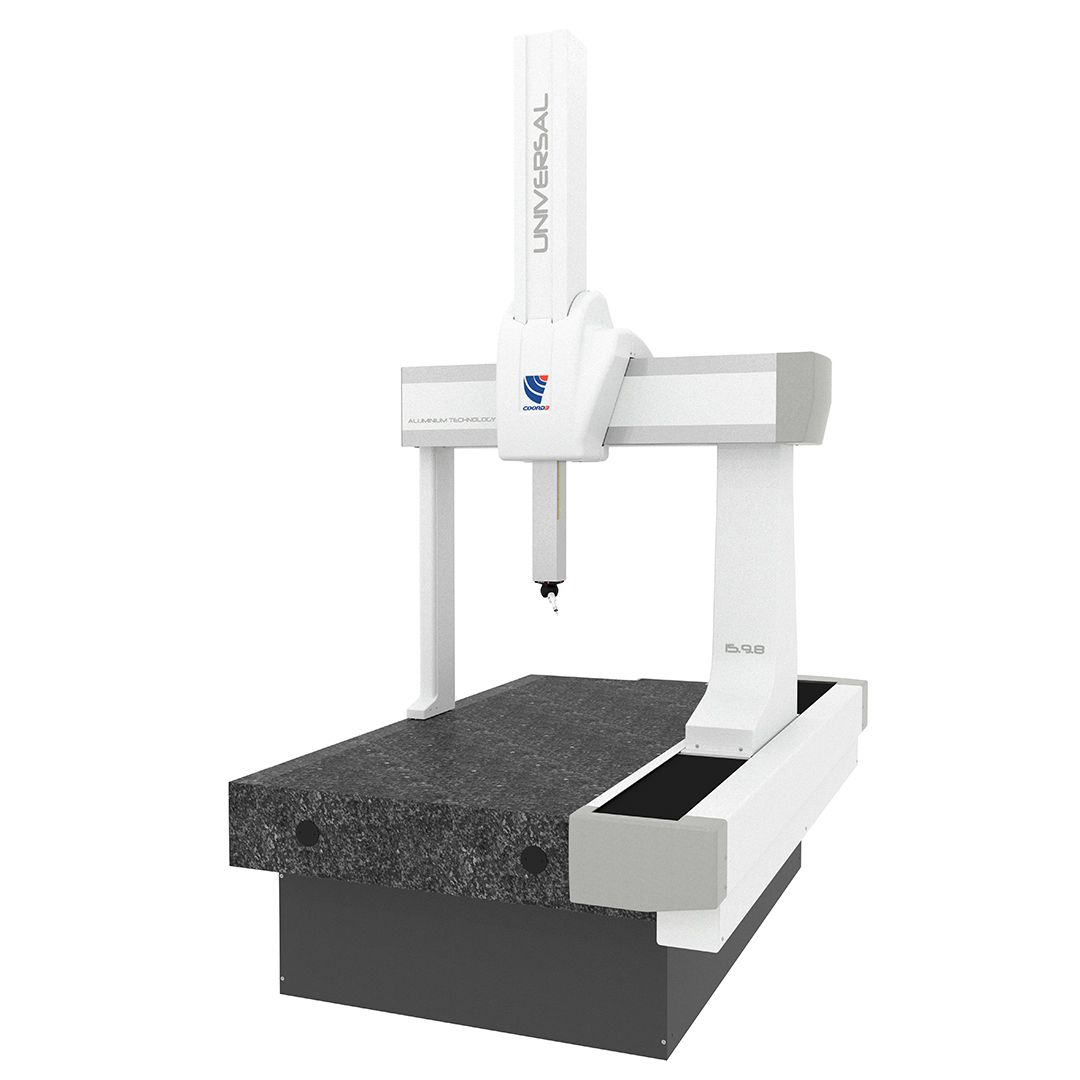

Coord 3, headquartered in Italy, is known for producing robust and adaptable CMMs suitable for industries such as aerospace, automotive, and general manufacturing. Their product lineup includes bridge, cantilever, and gantry-style machines that emphasize modularity, strength, and versatility.

Coord 3 machines support PC-DMIS software and are compatible with a wide array of tactile and optical sensors. Their design focus on mechanical rigidity and thermal compensation enables consistent and accurate measurements, especially on large or geometrically complex parts. Their systems are engineered to perform reliably in both lab and shop floor settings.

| Model | Measurement Range | Accuracy | Key Features |

|---|---|---|---|

| Ares | 500x500x400mm to 2000x1500x1000mm | Up to ±2μm | Modular design, tactile and optical probe support, thermal compensation |

| MCT PLUS | 3000x2000x1500mm and above | ±2.5μm | Large-volume measurement, gantry structure, suitable for aerospace |

While both Tokyo Seimitsu and Coord 3 manufacture high-quality coordinate measuring machines, their design philosophies and market focuses differ significantly. Tokyo Seimitsu emphasizes precision and environmental control, making its machines ideal for semiconductor, aerospace, and medical industries where ultra-tight tolerances and traceability are required. Coord 3, on the other hand, provides more adaptable solutions for varied industrial applications, from automotive to heavy engineering.

In terms of precision, Tokyo Seimitsu models like the ZEISS XENOS offer superior accuracy, often below the sub-micron level, coupled with vibration isolation and thermal control. Coord 3 machines are slightly less precise but compensate with flexibility and scalability, such as the MCT PLUS’s ability to handle very large parts.

Sensor compatibility also varies. Coord 3 supports a broad range of tactile and optical sensors, integrating seamlessly with automation and PC-DMIS environments. Tokyo Seimitsu, while primarily focused on Zeiss’s ecosystem, delivers deeper integration and consistency in scanning applications due to its close alignment with CALYPSO software and Zeiss probes.

Software-wise, Tokyo Seimitsu relies on CALYPSO, known for structured programming and parametric inspection strategies. Coord 3’s use of PC-DMIS provides a more familiar interface for users in globally distributed manufacturing environments, supporting advanced automation and CAD-based inspection routines.

Structurally, Tokyo Seimitsu CMMs are often built on granite bases with air bearings and are suited for cleanrooms or lab-based measurement, ensuring long-term stability. Coord 3 offers more rugged machines that can handle the thermal and mechanical stresses of a production environment without sacrificing measurement integrity.

Regarding service and support, Tokyo Seimitsu offers exceptional localized service in Japan and parts of Asia, providing quick response times and technical depth. Coord 3, leveraging its global reach and partnerships, offers widespread service and integration options for multinational operations.

Overall, Tokyo Seimitsu shines in environments demanding utmost precision and environmental control, while Coord 3 excels in flexibility, scalability, and shop-floor compatibility. The right choice depends on your production context, measurement needs, and operational footprint.

Tokyo Seimitsu is best suited for users requiring sub-micron precision in cleanroom or laboratory environments—such as manufacturers in the semiconductor, medical, or aerospace sectors. Their systems provide unmatched stability and integration with Zeiss technologies.

Coord 3 is ideal for manufacturers seeking flexibility, scalability, and compatibility with PC-DMIS environments—particularly in automotive, general manufacturing, or large-part inspection where rugged design and operational versatility are important.

Both Tokyo Seimitsu and Coord 3 offer powerful solutions in the CMM market, each catering to different priorities. Tokyo Seimitsu stands out in ultra-precise, controlled environments, while Coord 3 delivers scalable, versatile systems ready for a variety of industrial challenges. By understanding their core strengths, businesses can make informed decisions to enhance their quality control processes and production efficiency.