Coordinate measuring machines (CMMs) measure three-dimensional coordinates and dimensions by making contact with an object using a spherical stylus at the end of the measuring probe.

While bridge-type CMMs are the most common, recent years have seen the emergence of handheld CMMs that boast caliper-like operability. They are user-friendly and capable of high-precision measurements, even for beginners. Here, we introduce various contact method CMMs offered by different manufacturers. Be sure to check them out if you are considering implementing a CMM.

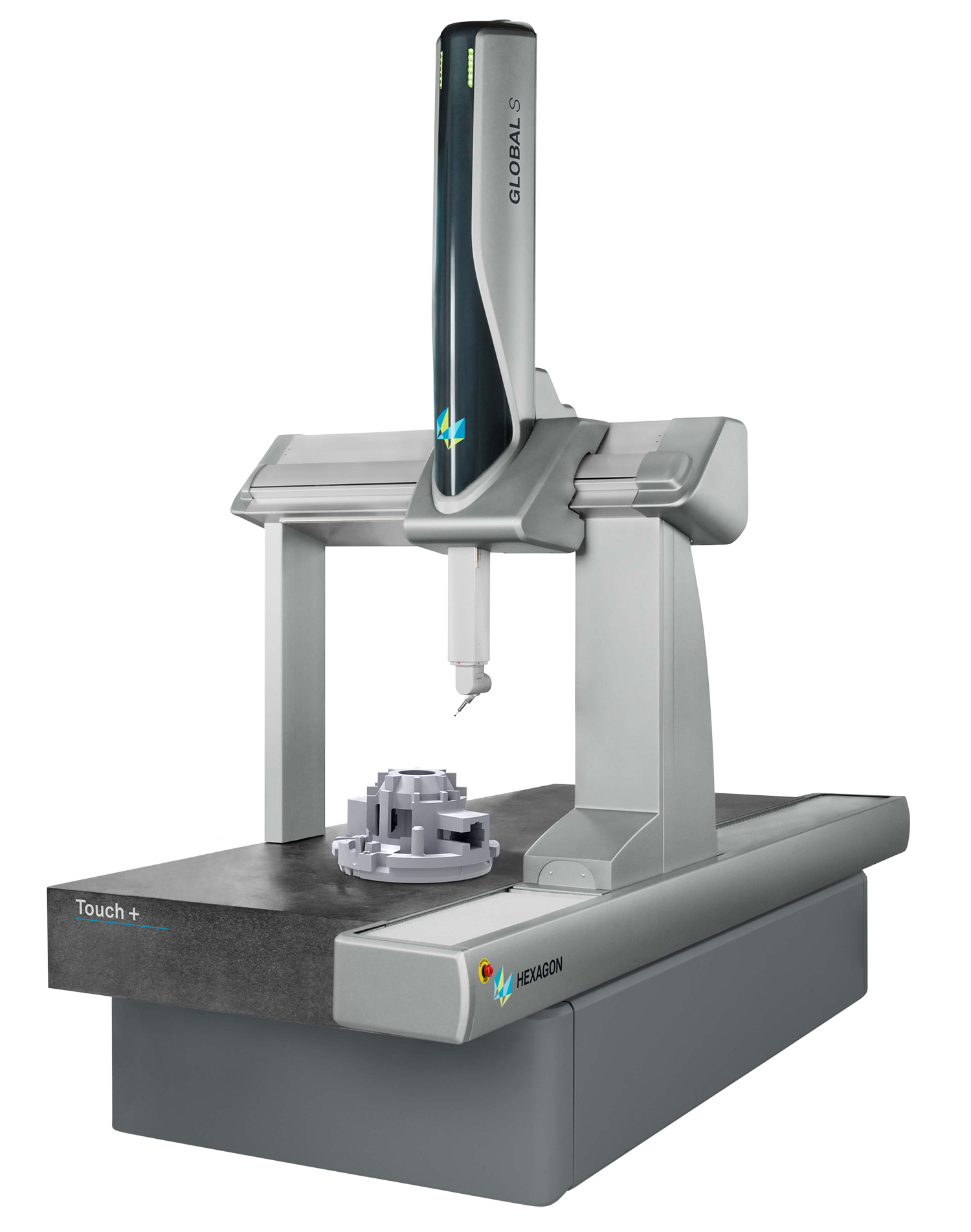

GLOBAL Touch+ is equipped with an electric index probe head and a six-direction touch-trigger probe, offering high versatility and exceptional single point tactile measurement performance. This setup guarantees high-precision measurements for complex 3D part shapes.

A key feature of GLOBAL Touch+ is its electric index probe head with an integrated six-direction touch-trigger probe. This probe allows for highly reproducible 3D point measurements on various sides of a workpiece. The machine also includes a flexible probe module exchange rack, enabling quick changes between probe modules with different trigger forces and stylus configurations, rationalizing the measurement cycle.

GLOBAL Touch+ delivers reliable and high-precision measurements across various fields, including plastic molding parts, mechanical components, and hinge joints.

ZEISS DuraMax offers precise measurements in a compact design. It features linear guides and a linear drive mechanism and notably does not require air supply, making it suited for workshop environments while reducing equipment and running costs.

Furthermore, it comes standard with a universal measurement program, Calypso, equipped with a filter compliant with roundness standards. It enables analysis using methods similar to those used in roundness measuring machines, allowing for the evaluation of geometric tolerances and deviations such as roundness and flatness.

The XM Series from KEYENCE is a versatile CMM that doesn’t require a large installation space or temperature control, making it easy to use at any desired location. The camera part can be detached from the stage, allowing measurements on the floor or directly on the machine. Because of this, it has a wide range of applications.

The operation is intuitive: Simply touch the workpiece with the handheld probe. With built-in tutorial functions, even beginners can operate it easily without a manual.

The XM Series boasts high performance with a measuring range of up to 2 meters, suitable for large workpieces. Its unique structure always captures the workpiece at the lens center, achieving repeatability of ±3μm. The camera’s field of view allows the probe to approach the workpiece from various angles, making it easy to handle.

This series is ideal for flexible measurement needs in various environments and is a valuable addition to existing CMMs in use.

The WM Series is a handheld CMM capable of measuring large workpieces up to 15 meters in size. Combining contact probes it can perform dimensional easily.

The handheld probe's position and orientation are constantly tracked by the main unit's camera, allowing for instant recognition of its location regardless of the operator’s position. This enables single-operator measurement of large workpieces without the need to move them. In-situ measurements can be made without unloading the workpiece from the machine tool, and inspection reports with photos of the measured areas can be created on the spot, significantly enhancing efficiency.

Setting up the WM Series is straightforward, involving only the connection of two cables. Operation is easy: select the measurement element on the monitor, touch the object with the probe, and press a button. Communication between the camera and PC is wireless, facilitating use in confined or complex areas and easy camera movement . The system also accommodates workpieces with height thanks to its lifting capability.

This series is recommended for those who want to measure large workpieces efficiently, in environments where traditional bridge-type CMMs, calipers, or micrometers may be inadequate, and for those who need the flexibility to measure in various locations.

Source: KEYENCE Website(https://www.keyence.com/products/measure-sys/cmm/xm/index_pr.jsp)

This CMM has a caliper-like feel, enabling even beginners to perform high-precision measurements. It can be carried without the need for temperature control, allowing for immediate measurements at any desired location and time. As it doesn't require a large installation space, it's a CMM with a low entry barrier.

Source: Carl Zeiss Website(https://www.zeiss.com/metrology/products/systems/cmm.html)

Utilizing linear drive on all axes, this CMM boasts high precision with a maximum permissible length measurement error of 0.3+L/1000μm, repeatability of ±0.2μm, and resolution of 0.001μm. The reduced occurrence of errors allows for a decrease in the need for remeasurement.

Source: Mitutoyo Website(https://www.mitutoyo.com/products/coordinate-measuring-machines/)

A CNC CMM that was first developed in 1976.

It features applications that respond to the demand for "Smart Factories" by allowing monitoring of operational status and maintenance management of the machine through the network.

Reasons for Selection