Coordinate Measuring Machines (CMMs) serve as critical assets in the manufacturing and quality assurance sectors, offering dimensional verification with high precision. Among respected providers, Coord 3 and Wenzel each bring unique strengths rooted in European engineering tradition. This article presents a detailed comparison of their CMM technologies—focusing on core features, technical specifications, and user suitability—without assigning superiority, to guide decision-makers seeking the best fit for their operational environments.

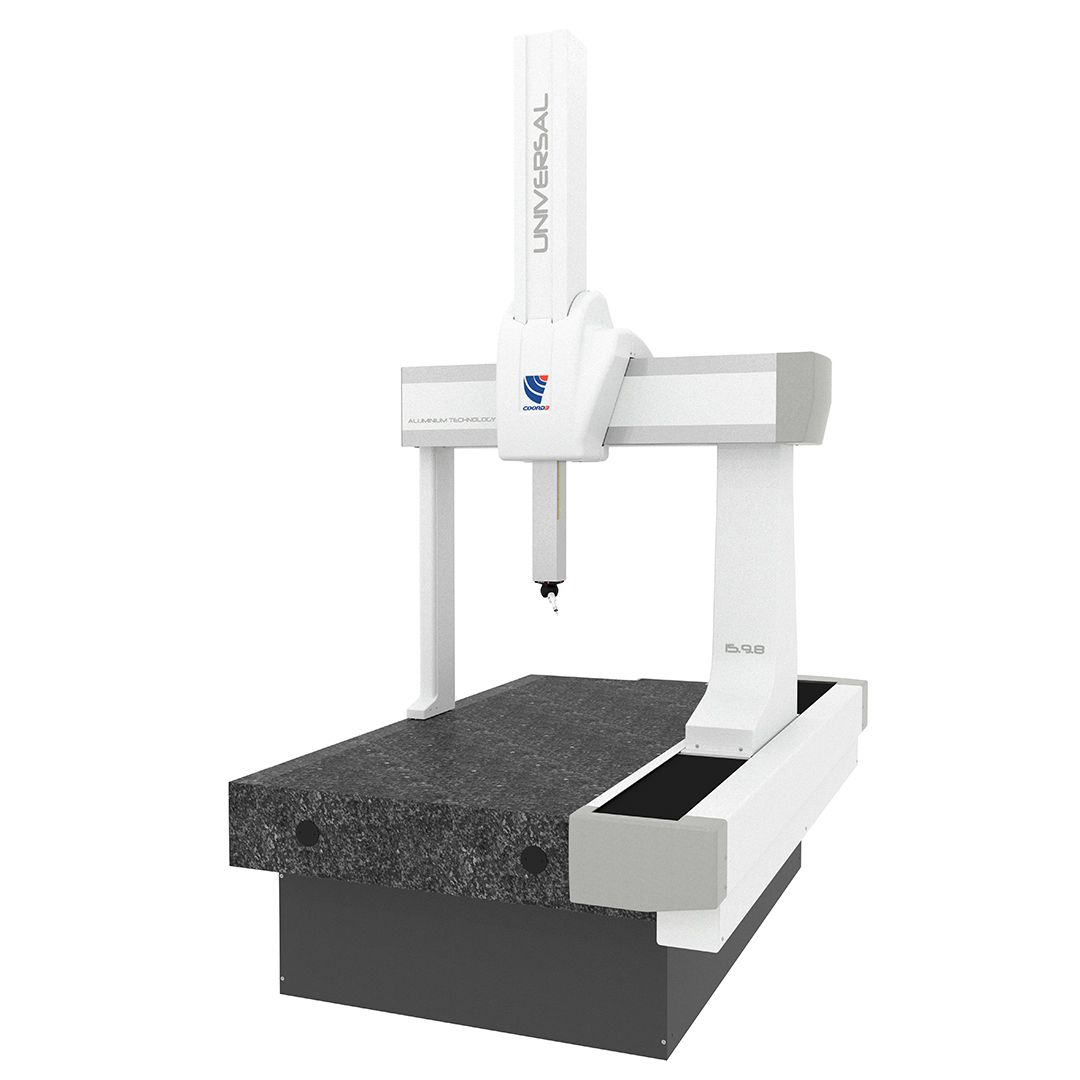

Coord 3, based in Italy, specializes in mechanically stable and versatile coordinate measuring machines. Their lineup spans from compact models for general manufacturing to gantry-type systems for large-scale parts in aerospace or heavy industry. Known for strong mechanical integrity and thermal stability, Coord 3 machines are designed to deliver reliable measurements in both lab and production environments.

Coord 3 CMMs support PC-DMIS software and allow integration with tactile and optical sensors, including laser probes. With modular machine architecture and customizable configurations, users can tailor systems to specific inspection tasks. Their robust build supports precise measurements even on complex geometries and large parts under varying temperature conditions.

| Model | Measurement Range | Accuracy | Key Features |

|---|---|---|---|

| Ares | 500x500x400mm to 2000x1500x1000mm | Up to ±2μm | Modular design, tactile and optical probe support, thermal compensation |

| MCT PLUS | 3000x2000x1500mm and above | ±2.5μm | Gantry design, large-scale inspection, aerospace suitability |

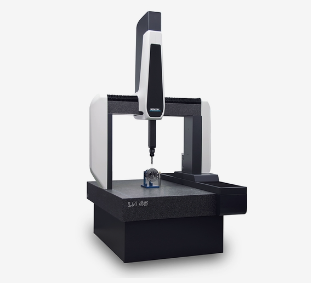

Wenzel, a German manufacturer with a legacy of over five decades, is known for precision-focused metrology systems. Their CMMs are built with natural granite bases for maximum thermal and structural stability. Wenzel’s portfolio includes bridge, gantry, and horizontal-arm CMMs, enabling solutions for everything from small components to massive aerospace assemblies.

The machines support tactile, optical, and laser scanning technologies, and offer compatibility with popular software platforms. With customizable modular configurations, Wenzel provides users with the flexibility to scale measurement solutions over time. Their emphasis on mechanical design, vibration isolation, and durable performance makes them highly suitable for both cleanroom and heavy industrial environments.

| Model | Measurement Range | Accuracy | Special Features |

|---|---|---|---|

| LH 2015 Gantry | 2000x3000/4000/5000x1500 mm | ±2.6 + L/450 μm | Granite structure, air bearings, optional vibration damping |

| RA Series Horizontal Arm | Custom configurations | Standard and Premium accuracy classes | Modular layout, suitable for large and heavy components |

Coord 3 and Wenzel both provide high-performance CMMs, but they differ in design philosophies, structural emphasis, and software flexibility. Coord 3 machines are recognized for modularity and compact design, making them suitable for manufacturers who value adaptable solutions with PC-DMIS integration. Wenzel machines, on the other hand, are typically more rugged, with granite constructions that ensure superior thermal stability and vibration resistance.

Sensor support is strong on both sides—Coord 3 emphasizes compatibility with multiple probe types and optical tools, while Wenzel delivers versatile multi-sensor capabilities, including advanced laser scanning. Wenzel’s systems are also more likely to feature factory-ready configurations for extremely large parts, due to their scalable gantry and horizontal-arm lines.

In terms of software, Coord 3 primarily utilizes PC-DMIS, offering a familiar and widely used platform with powerful inspection automation. Wenzel CMMs are more open-ended, allowing compatibility with several advanced software suites depending on application and user preference.

Structurally, Wenzel machines are distinguished by their use of natural granite and advanced damping techniques, making them a strong choice for high-end labs or facilities needing long-term accuracy. Coord 3’s strength lies in its mechanical simplicity and thermal compensation features, which deliver reliable results even in production environments with fluctuating temperatures.

Service and support also differ. Wenzel has a strong global service network and training ecosystem, while Coord 3 maintains a dedicated European base with growing international representation. Users with existing infrastructure around PC-DMIS may find Coord 3 easier to implement, while Wenzel’s bespoke system integration suits complex or high-stakes measurement scenarios.

Coord 3 is ideal for companies that value mechanical flexibility, PC-DMIS integration, and scalable measurement systems. Their machines suit mid-size production floors, precision machine shops, and aerospace parts manufacturers requiring adaptable CMMs that grow with their business.

Wenzel is best suited for manufacturers requiring ultra-stable, heavy-duty CMMs with laser scanning options. Ideal sectors include automotive, aerospace, and industrial machinery, where accuracy over large volumes and in harsh conditions is crucial.

Coord 3 and Wenzel each offer distinct advantages within the CMM landscape. Coord 3 combines Italian design with functional versatility, offering modular systems that adapt to evolving inspection needs. Wenzel provides German-engineered robustness and exceptional structural stability, tailored to rigorous metrology applications. Your choice should align with your production volume, accuracy requirements, and software preferences. Both brands continue to innovate, ensuring precise measurements for a wide range of manufacturing sectors.