Coordinate Measuring Machines (CMMs) are essential in modern manufacturing for ensuring the dimensional accuracy of complex parts. Coord 3 and Faro represent two distinctly different approaches to CMM design. While Coord 3 focuses on large-scale, high-precision systems with structural rigidity, Faro specializes in portable, flexible systems ideal for fast and mobile inspections. This article compares these two manufacturers to help users understand their differences and select the system that best fits their measurement needs.

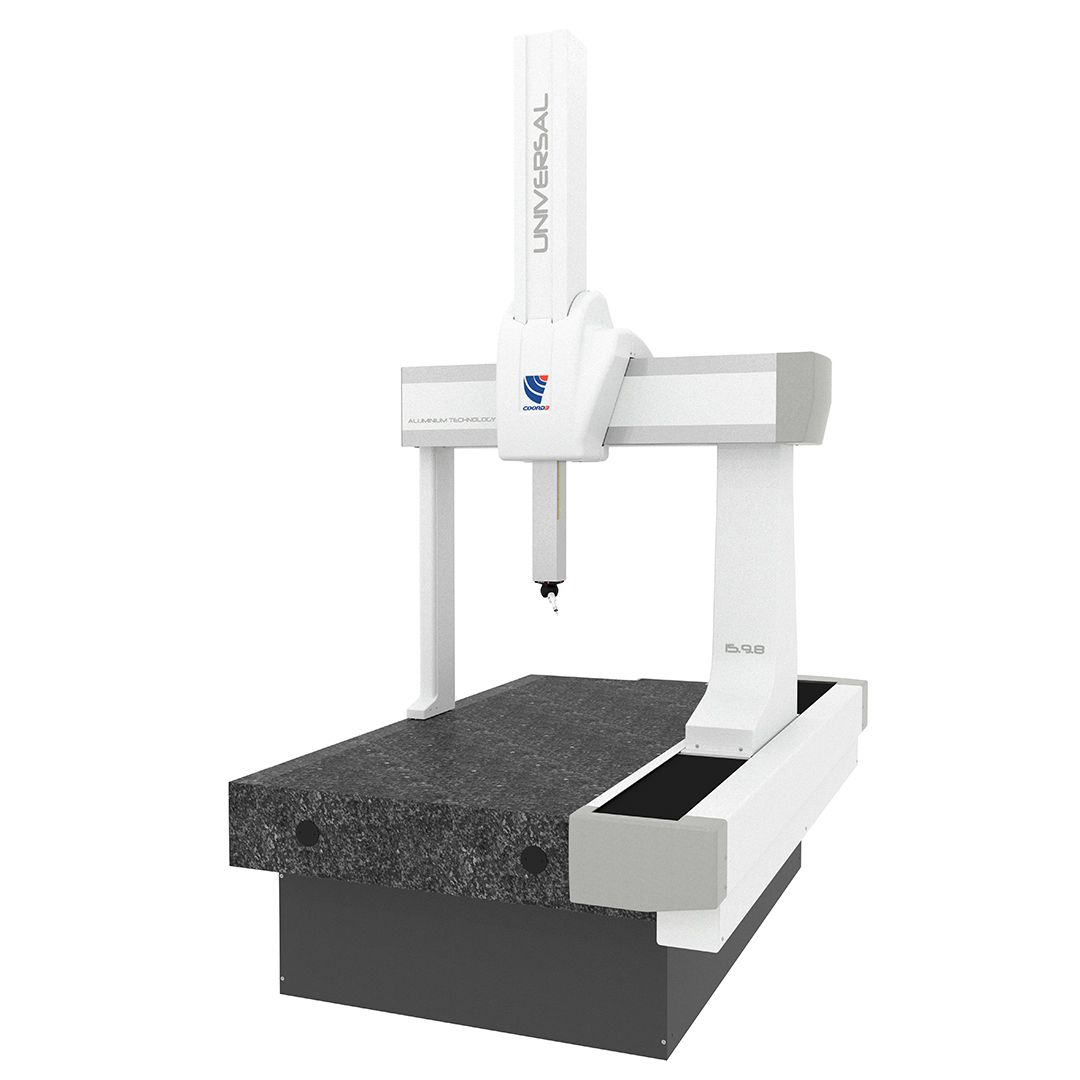

Coord 3, based in Italy, is known for developing high-accuracy CMMs suitable for controlled inspection environments. Their systems, including bridge and gantry types, are built with a focus on thermal stability and mechanical rigidity. Coord 3 supports industry-standard software like PC-DMIS and accommodates a wide range of tactile and optical probes, making their machines ideal for CAD-integrated measurement tasks.

These systems are well-suited for industries like aerospace and automotive, where dimensional tolerance and consistency are paramount. Coord 3 CMMs are often chosen for integration into automated quality control lines or high-volume inspection stations that demand reliable and repeatable results.

| Model | Measurement Range | Accuracy | Key Features |

|---|---|---|---|

| Ares | 500x500x400mm to 2000x1500x1000mm | Up to ±2μm | Modular design, tactile/optical compatibility, thermal stability |

| MCT PLUS | 3000x2000x1500mm and above | ±2.5μm | Large-volume inspection, gantry style, ideal for aerospace |

Faro has made its name as a leader in portable metrology solutions. Their articulated arm CMMs are highly mobile and suited for on-site inspections or workspaces without fixed measurement infrastructure. The FaroArm series includes 6-, 7-, and 8-axis systems that support tactile and laser scanning workflows.

Faro's CAM2 software simplifies tasks like part alignment, feature inspection, and CAD comparisons. These CMMs are often used for reverse engineering, rapid prototyping, and quality assurance in real-world environments such as machine shops or production lines. The design of Faro's systems allows for intuitive operation even by non-metrology specialists.

| Model | Measurement Range | Accuracy | Special Features |

|---|---|---|---|

| Gage Max | 1.2 m working volume | ±0.018 mm | Compact 6-axis, wireless use, portable setup |

| FARO ARM 8-Axis | Up to 4 m | ±0.029 mm | Rotating platform, 8-axis motion, reverse engineering support |

Coord 3 and Faro represent contrasting CMM philosophies. Coord 3 specializes in fixed, high-rigidity machines that deliver outstanding precision in temperature-controlled environments. These systems are often integrated into automated manufacturing lines where consistent throughput and micron-level accuracy are required.

In contrast, Faro focuses on portability and speed. Their articulated arms are ideal for workshops and field operations where measurement needs vary or infrastructure for fixed CMMs is unavailable. Faro systems are plug-and-play in many cases, requiring minimal setup, which is valuable for time-sensitive tasks or mobile teams.

While Coord 3 supports more traditional CMM architectures, Faro breaks this mold by prioritizing operator freedom and real-time feedback. Coord 3 CMMs often remain stationary and demand controlled conditions, while Faro devices can adapt to different surfaces and positions, even allowing users to walk around the part during inspection.

In terms of accuracy, Coord 3’s bridge and gantry machines tend to achieve tighter tolerances in large-scale applications. Their robust structure allows for better thermal compensation and mechanical stability. Faro offers impressive precision for a portable device, though typically not at the sub-micron level required in ultra-precise applications.

Sensor integration also varies significantly. Coord 3 systems are optimized for touch-trigger and scanning probes, with optical probe support where needed. Faro excels in integrating laser scanners and managing large point cloud data, which is crucial for reverse engineering or inspecting freeform surfaces.

Software is another differentiator. Coord 3 relies on PC-DMIS, a well-known platform for structured, CAD-driven inspection routines. Faro's CAM2 software prioritizes real-time measurement and user-friendly interfaces, reducing the learning curve for operators outside of metrology departments.

Ultimately, the choice between Coord 3 and Faro depends on the environment and objectives. Coord 3 is better suited to stable, high-precision workflows with room for fixed installation. Faro is more aligned with dynamic settings requiring flexibility, mobility, and fast inspection cycles. Both deliver excellent solutions in their respective domains.

Coord 3 CMMs are well-suited for manufacturers in aerospace, automotive, and industrial equipment who prioritize stability, CAD integration, and scalable accuracy in permanent installations.

Faro CMMs are ideal for users in prototyping, maintenance, and mobile inspection tasks, such as in tooling workshops, service teams, or design validation labs where portability and fast setup matter most.

Coord 3 and Faro offer complementary solutions in the coordinate measuring space. Coord 3 emphasizes accuracy, rigidity, and automation-readiness, making it ideal for high-end production environments. Faro’s mobile, easy-to-use systems are designed for speed and accessibility, thriving in less structured or time-sensitive settings. The best CMM for your operation depends on the balance between mobility, precision, and operational environment.