Coordinate Measuring Machines (CMMs) play a critical role in quality assurance and manufacturing, ensuring dimensional accuracy and consistency across industries. Zeiss and Mitutoyo are two prominent names in this space, each offering systems designed for specific needs, environments, and workflows. Rather than ranking one above the other, this article presents a side-by-side exploration of both manufacturers—their unique approaches, technological strengths, and the typical scenarios in which they shine.

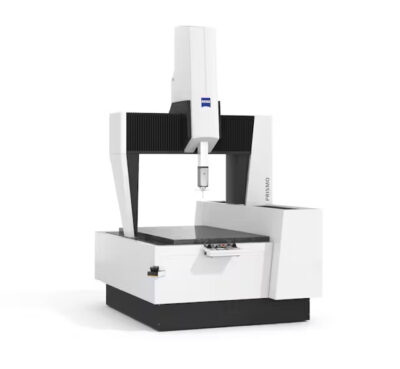

Zeiss is widely regarded as a pioneer in high-end metrology solutions. The company’s CMM lineup includes highly accurate bridge-type systems, multi-sensor platforms, and computed tomography (CT) solutions, addressing both standard and niche measurement tasks. Zeiss machines are known for precision, consistency, and adherence to international standards like ISO 10360.

One of Zeiss's standout features is sensor flexibility. Whether you require tactile probing, non-contact scanning, or full CT inspection, Zeiss systems can be configured accordingly. This allows manufacturers to address complex geometries or delicate components with confidence.

The software platform CALYPSO is another core strength. Deep CAD integration, automation routines, and advanced reporting functions make it powerful for users seeking in-depth analysis and reproducibility. While training is required, the software scales well from basic to expert use cases.

Below is a summary of two representative models:

| Model | Measurement Range | Accuracy | Key Features |

|---|---|---|---|

| CONTURA | X: 700–1200 mm, Y: 700–2400 mm, Z: 600–1000 mm | 1.4 + L/350 µm | Bridge-type, multiple probe options, flexible software |

| PRISMO Ultra | Various configurations | 0.5 µm + L/500 | Ultra-high precision, air bearings, damped granite bed |

Mitutoyo is a globally respected manufacturer with a robust portfolio of coordinate measuring machines. Their systems are engineered for precision, reliability, and adaptability to shop-floor environments. With decades of experience in dimensional metrology, Mitutoyo offers solutions from basic inspection to advanced automated inspection lines.

The CRYSTA-Plus series delivers affordability without sacrificing accuracy, making it a popular choice for small to medium-sized parts. On the other hand, the MiSTAR 555 is designed for real-time, shop-floor use and incorporates thermal compensation and vibration resistance to maintain performance in harsh conditions.

Mitutoyo’s software ecosystem, especially MCOSMOS, allows integration of measurement data into broader quality control systems. Users benefit from modular tools for reporting, SPC analysis, and CAD-based programming.

| Model | Measurement Range | Accuracy | Key Features |

|---|---|---|---|

| CRYSTA-Plus M544 | 500 x 400 x 400 mm | 2.2 + 3L/1000 µm | Bridge-type, cost-effective, versatile probes |

| MiSTAR 555 | 500 x 500 x 500 mm | 1.7 + 3L/1000 µm | Shop-floor ready, high-speed scanning, temperature compensation |

Though both brands deliver high-quality CMMs, their approaches reflect different priorities. Zeiss leans toward ultra-high precision and advanced sensor integration, making it suitable for demanding tasks in controlled environments. Mitutoyo, in contrast, emphasizes usability and environmental resilience, excelling in dynamic or production-floor settings.

In terms of software, Zeiss’s CALYPSO is powerful and integrates tightly with CAD workflows. Mitutoyo’s MCOSMOS offers similar benefits but is often considered more accessible in shop-floor contexts. Sensor options are rich in both systems, although Zeiss tends to push the envelope further with CT and high-speed optical systems.

Mitutoyo systems are often more budget-friendly and easier to deploy, especially for companies scaling up their metrology capabilities. Zeiss systems, while more costly, offer unmatched accuracy for organizations requiring top-end dimensional control.

Zeiss is ideal for research labs, aerospace manufacturers, and precision medical device makers that demand nanometer-level repeatability and highly automated processes. It suits users who invest in metrology as a long-term strategic asset.

Mitutoyo serves a broader user base, from SMEs to large automotive suppliers. Its models fit well in production lines, QA labs, and flexible inspection setups where real-world environmental conditions are a consideration. The learning curve is typically less steep, and maintenance is streamlined.

Zeiss and Mitutoyo both offer reliable, innovative solutions for coordinate measurement. Zeiss prioritizes ultimate precision and configurability, while Mitutoyo emphasizes versatility, robustness, and cost-effectiveness. Choosing between them depends on your specific requirements—accuracy demands, operational conditions, budget, and team expertise. Understanding each brand’s strengths enables better investment decisions and ensures long-term measurement success.