Coordinate Measuring Machines (CMMs) are critical instruments in industrial metrology, ensuring that manufactured components meet exacting dimensional specifications. Two respected manufacturers in this field—Tokyo Seimitsu and Wenzel—offer CMM solutions tailored to different needs. This article outlines the core characteristics of each brand's machines, explores their technical distinctions, and helps identify which might be more suitable depending on application requirements and industry sectors.

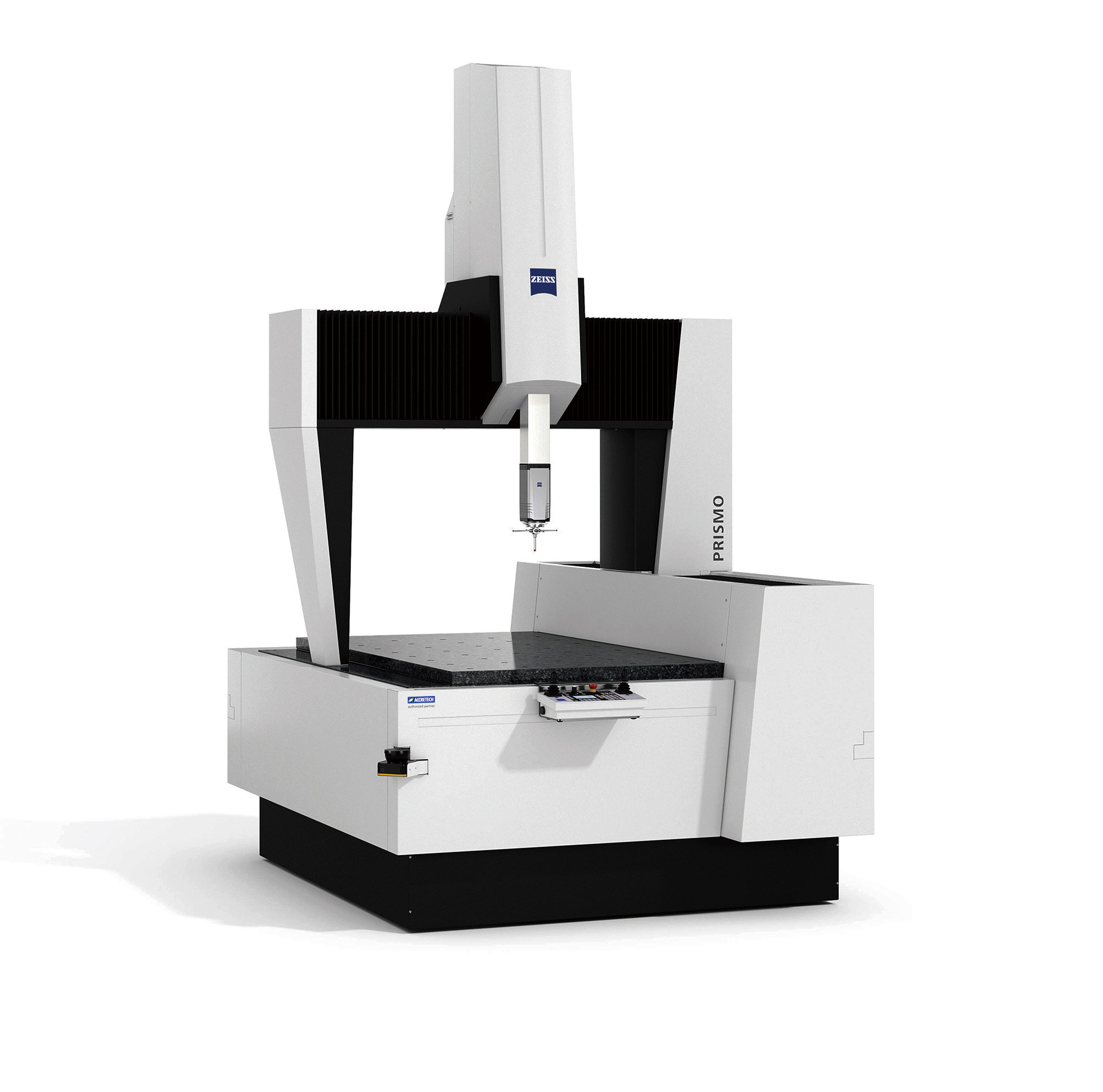

Operating under the ACCRETECH brand, Tokyo Seimitsu is a major force in precision metrology across Asia. Partnered with Zeiss since 1995, Tokyo Seimitsu integrates Zeiss sensor technologies and software into its CMMs, resulting in machines optimized for extreme accuracy, environmental resilience, and complex inspection routines.

Their CMMs are engineered for thermal and mechanical stability, often incorporating vibration isolation, granite construction, and air-bearing systems. Software integration with Zeiss CALYPSO allows for advanced measurement strategies, including parametric inspection programs, structured data reporting, and integration with quality control systems.

| Model | Measurement Range | Accuracy | Special Features |

|---|---|---|---|

| ZEISS XENOS | 850 x 1200 x 1000 mm | ±0.3 μm | Ultra-high precision, air bearings, active vibration isolation |

| ZEISS PRISMO | 700 mm to 3000 mm (configurable) | ±0.9 μm | Multi-sensor compatibility, thermal compensation, fast scanning |

Source: WENZEL website

Source: WENZEL website

(https://en.wenzel-group.com/product-category/cmm-machines)

Wenzel, based in Germany, has built a reputation for sturdy, adaptable CMMs for over 50 years. Their machines are widely used across aerospace, automotive, and energy sectors. Unlike brands that emphasize sensor integration or proprietary software, Wenzel focuses on mechanical reliability and modularity. Their CMMs support tactile, optical, and laser-based sensors and are built using granite structures for optimal thermal stability.

Wenzel's software environment includes their proprietary WM | Quartis software, but their machines also support external platforms. Their systems are ideal for companies seeking scalable, customizable measurement solutions with options for both manual and automated configurations.

Source: WENZEL website

Source: WENZEL website

(https://en.wenzel-group.com/product-category/cmm-machines)

| Model | Measurement Range | Accuracy | Special Features |

|---|---|---|---|

| LH 2015 Gantry | 2000 x 3000–5000 x 1500 mm | ±2.6 + L/450 μm | Granite base, air bearings, vibration damping |

| RA Series Horizontal Arm | Customizable | Standard/Premium accuracy classes | Modular design, suitable for large/heavy parts, CNC/manual modes |

While both Tokyo Seimitsu and Wenzel deliver robust and precise CMMs, their product strategies and design philosophies diverge in important ways. Tokyo Seimitsu, leveraging its partnership with Zeiss, prioritizes extreme measurement precision and thermal control. Their machines are typically deployed in cleanroom environments and R&D facilities requiring sub-micron accuracy. Wenzel, on the other hand, leans into long-term mechanical stability and platform versatility, with a strong focus on large-format and heavy-part measurement.

Tokyo Seimitsu excels in ultra-high precision applications, offering features like active vibration isolation and environmental compensation. Their integration with Zeiss CALYPSO software allows for parametric inspection strategies ideal for industries requiring traceability and statistical process control. Wenzel’s strength lies in its customizable systems—particularly for industries that measure large, heavy, or complex parts. Their RA and gantry series provide significant flexibility in measurement volume and probe configuration, backed by granite stability.

Sensor compatibility also differs. Tokyo Seimitsu’s systems are optimized for Zeiss’s tactile and optical probes, including rotary scanning heads. Wenzel offers wider sensor platform integration, from Renishaw tactile probes to Nikon laser scanners, accommodating a broader spectrum of applications.

In terms of software, CALYPSO offers traceability and structured workflows, while Wenzel’s WM | Quartis is designed for intuitive operation and compatibility with third-party systems. This allows Wenzel users to adapt their metrology systems to a wide range of workflows and industries, without being locked into proprietary ecosystems.

When it comes to machine footprint, Tokyo Seimitsu emphasizes compactness and lab-ready installation, while Wenzel’s horizontal arm systems are often larger and geared toward factory-floor integration. Support strategies differ as well—Tokyo Seimitsu offers strong regional support in Japan and Asia, while Wenzel maintains a broad international service presence, ideal for companies operating across borders.

Tokyo Seimitsu is the optimal choice for industries like aerospace, semiconductor, or precision tooling, where nanometer-level accuracy and controlled environments are required. Their CMMs are designed for repeatability, cleanroom compliance, and advanced analytical functionality.

Wenzel is ideal for companies that manufacture large, heavy, or geometrically complex components—such as those in heavy machinery, transportation, and defense. Their flexible configurations and robust frames make them well-suited for demanding shop-floor applications.

Tokyo Seimitsu and Wenzel each offer compelling advantages in coordinate measurement, driven by different priorities. Tokyo Seimitsu shines in precision metrology through its Zeiss collaboration and laboratory-grade machines, while Wenzel emphasizes mechanical durability, configurability, and sensor openness. The best CMM for your application depends on whether you need pinpoint accuracy in controlled environments or adaptability across large-scale, production-oriented tasks. Both brands continue to innovate, ensuring strong choices for the future of dimensional quality assurance.