A coordinate measuring machine (CMM) is a measuring device that can capture the three-dimensional shape of an object. It is widely used not only in research and development but also in manufacturing environments for quality control, including measuring components such as gears for automobiles, cutting tools, and parts for aircraft engines.

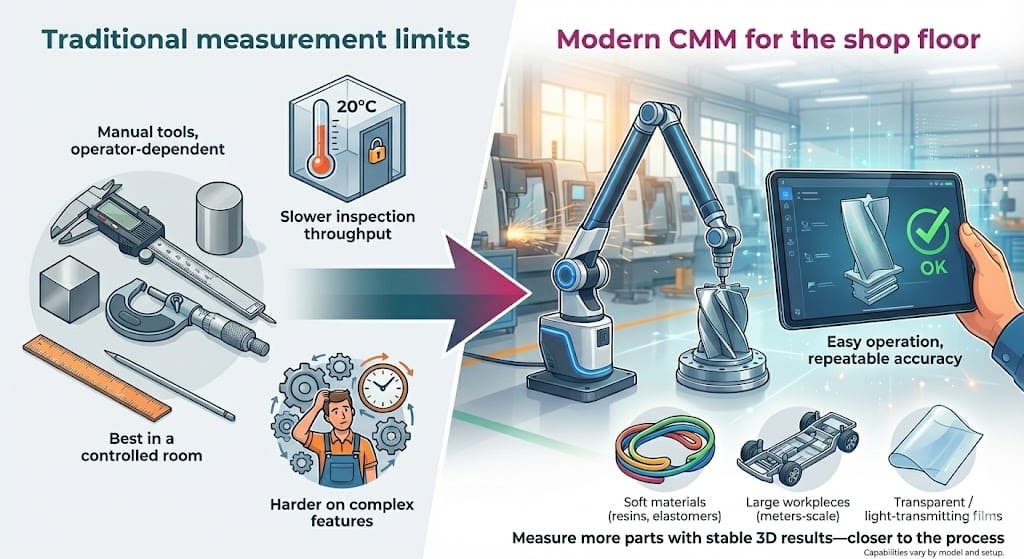

For simple shapes like rectangular prisms or circles, various measuring instruments such as rulers, tape measures, calipers, and micrometers can be used. For height measurements, a height gauge or a dial gauge can be employed.

Coordinate measuring machines (CMMs) can measure objects that are difficult to measure accurately with these traditional instruments, such as complex shapes like polygons and star shapes, soft materials like synthetic resins, large objects measuring several meters like automobiles, and soft, light-transmitting materials like transparent films.

Traditionally, CMMs were used in temperature-controlled measurement rooms. However, in recent years, there has been a growing demand for using them within manufacturing environments for tasks such as verifying the position of workpieces mounted on pallets before machining, checking precision during machining, and inspecting defects after machining.

There are now many CMMs that do not require a dedicated measurement room. These are portable, compact, and can be installed in various locations.

Traditional measuring instruments often face various challenges, such as variability in measurement results due to human error, limitations on the types of objects and measurement environments they can handle, high inspection labor costs, lack of skilled personnel to operate the equipment, and high costs for installation and management.

A coordinate measuring machine (CMM) solves these issues by allowing for precise measurements of any object, regardless of type, with appropriate setup in advance. This enables highly accurate measurements to be performed repeatedly.

In recent years, portable CMMs that do not require a dedicated measurement room and allow stable measurements in various environments, such as on the shop floor or in an office, have become available.

A coordinate measuring machine (CMM) addresses various issues associated with traditional measuring instruments, enabling high-precision three-dimensional measurements regardless of the object or environment. However, some CMMs require a controlled temperature environment and must be set up and operated with specialized knowledge and skills, so careful consideration is needed when choosing a model.

On this page, we introduce CMMs that do not require a measurement room nor specialized knowledge. It would be a good idea to check them out if you feel inconvenient with the CMM you are currently using.

Source: KEYENCE Website(https://www.keyence.com/products/measure-sys/cmm/xm/index_pr.jsp)

This CMM has a caliper-like feel, enabling even beginners to perform high-precision measurements. It can be carried without the need for temperature control, allowing for immediate measurements at any desired location and time. As it doesn't require a large installation space, it's a CMM with a low entry barrier.

Source: Carl Zeiss Website(https://www.zeiss.com/metrology/products/systems/cmm.html)

Utilizing linear drive on all axes, this CMM boasts high precision with a maximum permissible length measurement error of 0.3+L/1000μm, repeatability of ±0.2μm, and resolution of 0.001μm. The reduced occurrence of errors allows for a decrease in the need for remeasurement.

Source: Mitutoyo Website(https://www.mitutoyo.com/products/coordinate-measuring-machines/)

A CNC CMM that was first developed in 1976.

It features applications that respond to the demand for "Smart Factories" by allowing monitoring of operational status and maintenance management of the machine through the network.

Reasons for Selection