Coordinate Measuring Machines (CMMs) are indispensable in modern manufacturing for quality control and dimensional verification. Two of the most recognized names in this field—Hexagon and Mitutoyo—offer a range of CMM systems tailored to various industrial applications. This article provides an in-depth comparison of Hexagon and Mitutoyo CMMs, highlighting their differences and similarities without implying superiority. Our aim is to assist engineers and quality professionals in selecting the most suitable solution for their specific metrology needs.

Hexagon is a global leader in industrial metrology and smart manufacturing solutions. Their CMM lineup spans bridge, gantry, and horizontal-arm models, engineered for flexibility and precision. These machines are often chosen for their robust construction, automation compatibility, and cutting-edge sensor integration.

Hexagon supports tactile, optical, and laser sensors, allowing for high versatility in part inspection. One of Hexagon’s strengths lies in its proprietary software, PC-DMIS. This powerful platform facilitates CAD model integration, real-time data analysis, and advanced automation paths. It’s particularly beneficial in high-throughput environments where speed and reliability are essential.

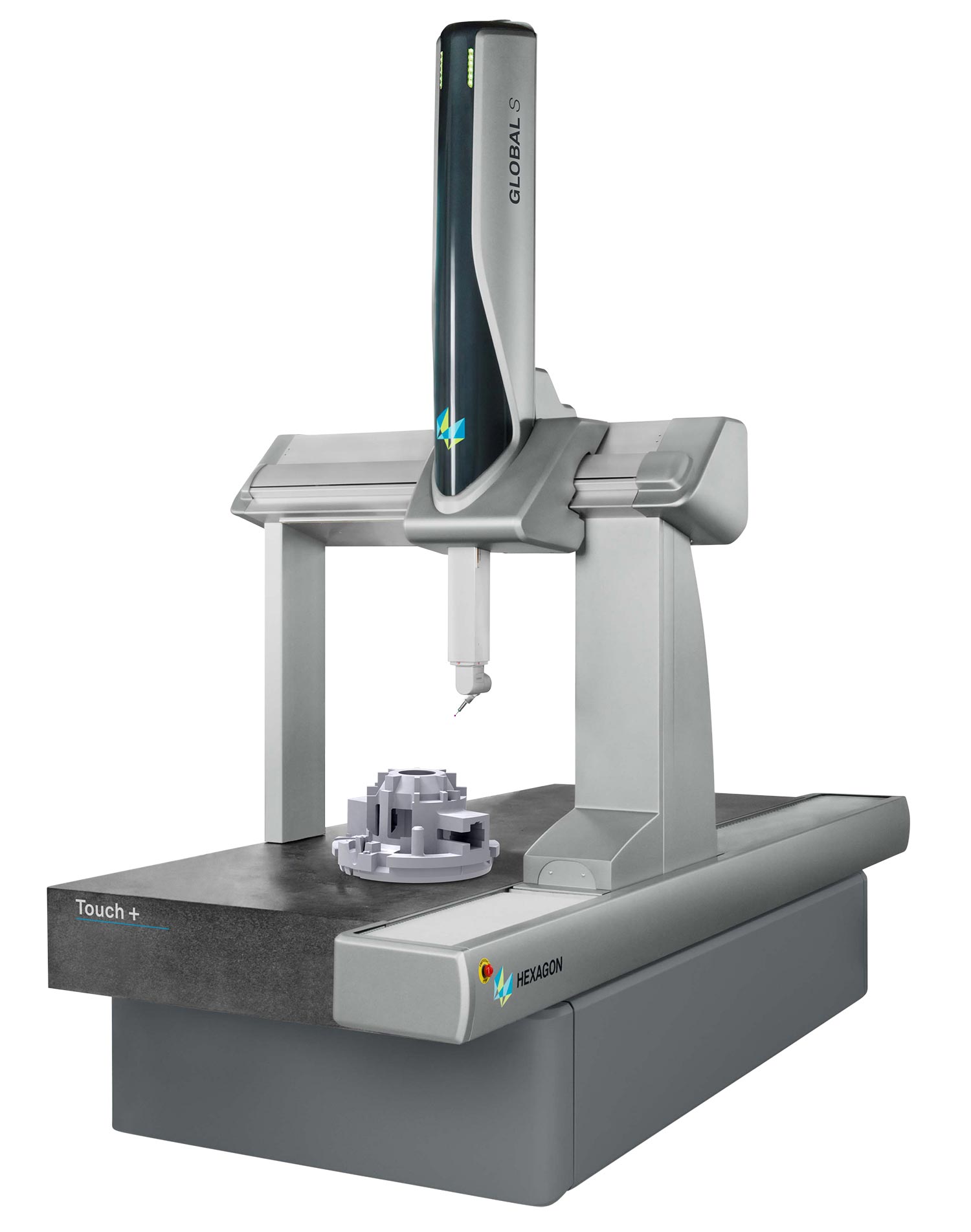

Hexagon places a strong emphasis on ease of use and real-time feedback. The GLOBAL Touch+ series incorporates touchscreen controls and visual feedback to enhance usability. This intuitive interface reduces training time and accelerates routine inspection workflows.

Two representative Hexagon models are summarized below:

| Model | Measurement Range | Accuracy | Special Features |

|---|---|---|---|

| ALPHA | Customizable (e.g., 1200 x 1500 x 1000 mm) | ±1.5 μm | High-accuracy bridge system, tactile sensors, automation ready |

| GLOBAL Touch+ | Varies by configuration | ±2 μm | Touchscreen interface, PC-DMIS compatible, user-friendly |

Mitutoyo has established a strong reputation in dimensional metrology, known for precision, affordability, and reliability. Their CMMs cater to a wide range of industries and offer solutions for both lab and shop-floor environments. Mitutoyo’s systems are particularly favored for their consistent performance and ease of maintenance.

The CRYSTA-Plus series is ideal for standard inspection tasks, offering high accuracy at a competitive price point. The MiSTAR 555 is optimized for shop-floor use, featuring real-time thermal compensation, robust build, and resistance to vibration. These features allow for dependable operation even in uncontrolled production environments.

Mitutoyo’s MCOSMOS software enables users to manage measurement data, perform SPC analysis, and execute CAD-based programming. This modular platform allows smooth integration into broader quality management systems.

| Model | Measurement Range | Accuracy | Key Features |

|---|---|---|---|

| CRYSTA-Plus M544 | 500 x 400 x 400 mm | 2.2 + 3L/1000 µm | Cost-effective, bridge-type, general-purpose use |

| MiSTAR 555 | 500 x 500 x 500 mm | 1.7 + 3L/1000 µm | Shop-floor ready, thermal and vibration resistant |

Hexagon and Mitutoyo CMMs both deliver reliable and advanced solutions for dimensional inspection, but they approach design and functionality with different philosophies.

In terms of precision, Hexagon systems generally offer slightly higher accuracy, particularly in high-end models like the ALPHA series. Mitutoyo's MiSTAR 555, though slightly less accurate on paper, provides superior performance in real-world manufacturing environments due to thermal and vibration controls.

Sensor flexibility is strong for both brands. Hexagon’s support for laser, tactile, and optical sensors—along with touchscreen interfaces—enhances usability and automation. Mitutoyo focuses on robust tactile scanning and offers high-speed options, particularly beneficial for small-to-mid-sized part inspection.

Software compatibility marks another distinction. PC-DMIS from Hexagon is more widely known in global operations and offers deep automation capabilities. Mitutoyo’s MCOSMOS, while modular and integrated, leans toward ease of use in Japanese and Southeast Asian markets.

Regarding architecture, Hexagon is more often chosen for complex CAD-driven workflows and automation. Mitutoyo offers more compact, cost-efficient systems that excel in hands-on environments with tighter budgets and higher operator interaction.

Hexagon is ideal for manufacturers in the aerospace, automotive, and defense sectors, where automated, high-precision measurement systems are essential. Companies with CAD-heavy environments or large-scale automation needs will benefit most from Hexagon’s capabilities.

Mitutoyo suits small to mid-size manufacturers looking for reliability, affordability, and real-time usability. Industries such as medical devices, electronics, and machinery production will appreciate Mitutoyo’s stability, especially in environments lacking strict climate control.

Hexagon and Mitutoyo both exemplify excellence in coordinate metrology. While Hexagon leads in automation readiness and sensor integration, Mitutoyo shines with cost-effective reliability and adaptability. The right choice depends on application complexity, environmental conditions, and long-term integration goals. Both companies continue to innovate, ensuring quality and precision for manufacturers worldwide.