Coordinate Measuring Machines (CMMs) are essential in modern manufacturing for precise dimensional verification. Among the many reputable CMM manufacturers, Zeiss and Wenzel stand out with robust technologies, each with its own strengths. This article explores the differences and similarities between Zeiss and Wenzel CMMs without ranking one over the other, aiming to help professionals identify which system better aligns with their measurement needs.

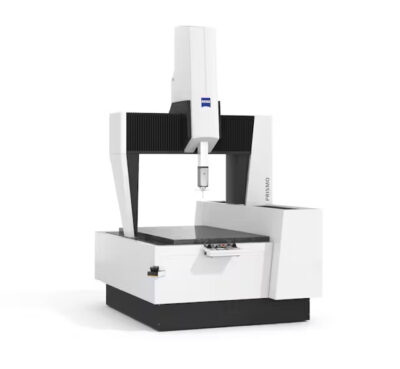

Zeiss is globally recognized for precision and innovation. Its CMM lineup includes bridge, gantry, and horizontal-arm systems designed to deliver exceptional repeatability and accuracy. Zeiss emphasizes structural stability through granite bases and air bearings, making their machines ideal for demanding environments.

Sensor modularity is a key Zeiss advantage. Their systems support tactile, optical, and X-ray sensors, enabling comprehensive inspection strategies across a range of part complexities. This flexibility supports integration into automated production lines or high-accuracy labs.

CALYPSO, Zeiss's proprietary software, offers parametric inspection plans, CAD model integration, and sophisticated automation routines. While it requires some training, it enables users to leverage advanced measurement capabilities efficiently once mastered.

Below is a comparison of two representative models from Zeiss:

| Model | Measurement Range | Accuracy | Key Features |

|---|---|---|---|

| CONTURA | X: 700–1200 mm, Y: 700–2400 mm, Z: 600–1000 mm | 1.4 + L/350 µm | Bridge-type, multiple probe options, flexible software |

| PRISMO Ultra | Various configurations | 0.5 µm + L/500 | Ultra-high precision, air bearings, damped granite bed |

Source: WENZEL website

Source: WENZEL website

(https://en.wenzel-group.com/product-category/cmm-machines)

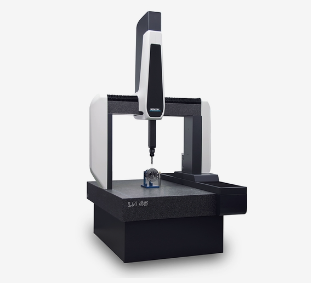

Wenzel is a German precision engineering company with over five decades of experience in metrology. Known for their robust construction and adaptability, Wenzel’s CMMs are suitable for various industries including aerospace, automotive, and heavy equipment manufacturing.

Wenzel systems are modular and come in multiple types including bridge, gantry, and horizontal-arm designs. They emphasize long-term mechanical stability and offer multi-sensor compatibility—tactile, optical, and laser scanners are all supported. The granite-based structure provides excellent thermal stability and vibration damping for reliable measurements.

Software integration is a strong point for Wenzel. Their CMMs can operate with Wenzel’s WM | Quartis software or third-party platforms, supporting workflows that range from manual part inspection to fully automated, CNC-driven metrology tasks.

Source: WENZEL website

Source: WENZEL website

(https://en.wenzel-group.com/product-category/cmm-machines)

Here are two representative models from Wenzel:

| Model | Measurement Range | Accuracy | Special Features |

|---|---|---|---|

| LH 2015 Gantry | 2,000 mm (X), 3,000/4,000/5,000 mm (Y), 1,500 mm (Z) | ±2.6 + L/450 μm | Granite construction, air bearings, optional active vibration damping |

| RA Series Horizontal Arm | Customizable based on application | Standard and Premium accuracy classes available | Modular design, suitable for large and heavy components, manual or CNC operation |

Zeiss and Wenzel both offer high-quality coordinate measuring machine (CMM) systems, yet they differ in several key aspects that can influence a user’s choice depending on application needs.

In terms of accuracy and precision, Zeiss is often the preferred option for ultra-high precision measurements, particularly with its PRISMO series. These machines are engineered for environments where sub-micron accuracy is critical. Wenzel also delivers reliable accuracy, though its strength lies in gantry and horizontal-arm designs that accommodate large and heavy components. These machines tend to have slightly looser tolerances but are optimized for size and accessibility.

When it comes to sensor flexibility, both brands support tactile and optical measurement technologies. However, Zeiss extends its capabilities further by incorporating X-ray computed tomography (CT), allowing for advanced non-destructive testing. Wenzel, in contrast, is known for its open architecture and compatibility with a wide range of third-party sensors, making it especially appealing in environments where integration with existing systems is necessary.

Software is another distinguishing factor. Zeiss uses its proprietary CALYPSO platform, which is robust and feature-rich but limited to its own ecosystem. Wenzel offers a more flexible software environment, primarily through WM | Quartis, while also supporting third-party software solutions. This makes Wenzel’s systems easier to integrate into diverse or mixed software environments.

Regarding machine architecture, Zeiss typically produces lab-grade CMMs that prioritize thermal stability and vibration isolation. These systems are well-suited for cleanroom or controlled measurement spaces. Wenzel, on the other hand, excels in large-format and customizable machines, with architectures designed to perform reliably even on the production floor.

Finally, the two brands take different approaches to modularity and system design. Wenzel emphasizes adaptability in its RA and LH series, allowing for easy reconfiguration as production needs evolve. Zeiss tends to focus on fixed, high-precision systems optimized for consistent performance in tightly controlled environments.

Ultimately, both companies offer exceptional products, but their core strengths and design philosophies cater to different metrology contexts.

Zeiss CMMs are best suited for industries where sub-micron precision is critical—such as aerospace components, medical devices, and high-performance automotive parts. Their systems are ideal for metrology labs and manufacturers with a dedicated quality control infrastructure and trained personnel.

Wenzel CMMs are excellent for companies requiring adaptable, large-scale measurement systems. Their modular architecture and software compatibility make them a good fit for workshops that handle oversized parts, such as heavy machinery, molds, or chassis components. Manufacturers needing flexibility and scalability will benefit from Wenzel’s open-system approach.

Zeiss and Wenzel represent two pillars of coordinate measurement excellence. Zeiss excels in delivering high-precision, lab-grade systems with sophisticated automation and sensor options. Wenzel, by contrast, focuses on flexibility, robustness, and cost-effective customization. The choice between the two depends largely on measurement goals, part sizes, production environments, and software integration requirements. Both brands continue to innovate and push the boundaries of what’s possible in dimensional metrology.