Coordinate Measuring Machines (CMMs) are critical tools in modern manufacturing, offering accurate, repeatable measurements across diverse components. Among the leading brands in this space, Mitutoyo and Wenzel have carved out strong reputations for precision, reliability, and innovation. While both manufacturers provide high-performance solutions, they differ in philosophy, technical approach, and industry fit. This article outlines their respective strengths and key differences to help manufacturers identify the right solution for their needs.

Mitutoyo, headquartered in Japan, is renowned for delivering highly accurate and reliable metrology systems. Their CMM lineup spans compact shop-floor units to advanced bridge-style and gantry systems, all engineered with durability, thermal compensation, and operator efficiency in mind. A notable highlight is the MCOSMOS software suite—designed for ease of use, integration with CAD, and support for both contact and non-contact sensors.

Mitutoyo’s flexibility in sensor integration—tactile, scanning, and laser—alongside stable mechanics and global support services makes it a go-to brand for manufacturers operating across diverse sectors. Their systems are well-suited for mid-sized part inspection, inline integration, and multi-site quality consistency.

| Model | Measurement Range | Accuracy | Special Features |

|---|---|---|---|

| CRYSTA-Plus M | 710 x 1000 x 660 mm | ±1.7 μm | Bridge CMM, multi-sensor compatibility, MCOSMOS software |

| MiSTAR 555 | 570 x 500 x 500 mm | ±2.2 μm | Shop-floor use, high speed, thermal compensation |

Source: WENZEL website

Source: WENZEL website

(https://en.wenzel-group.com/product-category/cmm-machines)

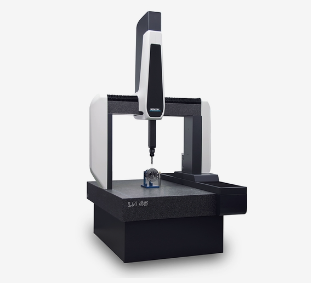

Wenzel, based in Germany, has over five decades of experience delivering robust, granite-based CMMs. The company offers bridge, gantry, and horizontal-arm models, often with customizable configurations. Wenzel’s emphasis on mechanical rigidity, modularity, and advanced sensor compatibility makes its systems particularly attractive to industries dealing with large components, such as aerospace and heavy equipment manufacturing.

Wenzel machines also integrate tactile, optical, and laser sensors and can be configured with software such as WM | Quartis for high-level inspection and reporting. Their systems are known for long-term structural stability, even under demanding environmental conditions, and allow both manual and fully automated operation.

Source: WENZEL website

Source: WENZEL website

(https://en.wenzel-group.com/product-category/cmm-machines)

| Model | Measurement Range | Accuracy | Special Features |

|---|---|---|---|

| LH 2015 Gantry | 2,000 mm (X), 3,000/4,000/5,000 mm (Y), 1,500 mm (Z) | ±2.6 + L/450 μm | Granite construction, air bearings, vibration damping |

| RA Series Horizontal Arm | Customizable | Standard and Premium classes | Large component support, modular build, CNC/manual |

Mitutoyo and Wenzel, while both focused on precision and reliability, serve somewhat different user needs. Mitutoyo places greater emphasis on universal usability, offering a broad range of models that work equally well in production lines and quality control labs. Their machines are generally more compact and easier to integrate into inline processes. Wenzel, by contrast, targets large-part applications with structural designs that prioritize rigidity and long-term dimensional stability.

In terms of software, Mitutoyo’s MCOSMOS supports seamless CAD integration, automated routines, and user-friendly interfaces, making it appealing for mixed-experience teams. Wenzel uses WM | Quartis, which is geared toward in-depth, structured inspections and supports complex GD&T evaluations. Both software platforms offer reporting, automation, and probe path optimization, but with different user interface philosophies.

Sensor flexibility is present in both brands, though Wenzel leans into high-resolution optical and laser configurations for large components. Mitutoyo provides a wider range of entry- to mid-level sensor options that suit general manufacturing environments. On the other hand, Wenzel’s focus on granite frames and air-bearing systems delivers superior vibration control and stability for heavy-duty use cases.

Physically, Mitutoyo machines are more adaptable to smaller spaces, with portable or semi-portable units like MiSTAR. Wenzel’s gantry and horizontal-arm machines, while larger, offer scalability for organizations managing oversized molds, automotive bodies, or aerospace frames. Additionally, Wenzel systems often allow for highly tailored builds, appealing to facilities requiring custom layouts.

Service infrastructure is another consideration. Mitutoyo has a globally distributed network with multilingual support, while Wenzel maintains a strong presence in Europe and North America, emphasizing direct relationships and long-term service contracts. For multinational manufacturers, Mitutoyo may offer more consistency across regions, whereas Wenzel offers high responsiveness in localized operations.

Ultimately, Mitutoyo delivers well-rounded, scalable solutions ideal for operations that balance speed, accuracy, and integration simplicity. Wenzel is better suited for applications where component size, mechanical stability, and configurability are paramount.

Mitutoyo is ideal for manufacturers who prioritize workflow efficiency, shop-floor inspection, and cost-effective quality control. Their systems serve general machining, electronics, medical, and automotive industries well, especially when consistency and usability are key.

Wenzel suits companies operating in heavy industries, aerospace, or mold and die sectors that need scalable, rigid systems capable of handling physically large components. Their modular approach also benefits organizations with evolving or highly specific metrology needs.

Both Mitutoyo and Wenzel offer world-class CMMs that fulfill different operational demands. Mitutoyo's edge lies in its software integration, broad usability, and global support network. Wenzel, meanwhile, provides structural excellence, configurability, and strength for high-load inspections. Choosing between them involves aligning machine characteristics with your specific application environment, inspection scale, and long-term service expectations.