Coordinate Measuring Machines (CMMs) are essential tools in manufacturing and quality control, ensuring dimensional precision and product reliability. Zeiss and Faro are both renowned in this field, offering innovative solutions tailored to diverse industry needs. This article compares their CMM offerings—highlighting similarities and differences—without ranking one over the other.

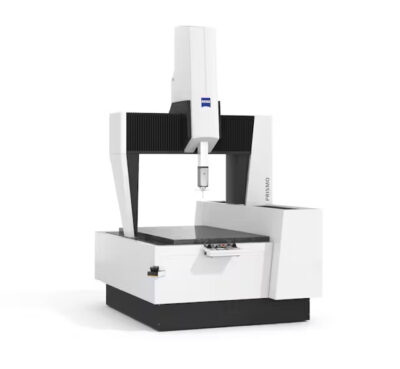

Zeiss CMMs are known for their exceptional mechanical stability and high precision. They are built using premium materials such as ceramic or granite for key structural components, which minimizes thermal expansion and enhances dimensional stability. Zeiss also integrates its proprietary scanning technologies—like VAST XT and VAST Gold—allowing for fast, continuous scanning of complex surfaces with minimal probing force. This is especially useful in industries such as aerospace, medical devices, and precision tooling.

Additionally, Zeiss CMMs feature active damping systems and air bearings on all axes, which contribute to smooth motion and consistent measurement accuracy. Most models are equipped with advanced temperature compensation algorithms and real-time error correction, ensuring optimal performance even in fluctuating shop-floor environments. Integration with Zeiss CALYPSO software provides intuitive workflows and automated measurement routines, reducing operator dependency and improving throughput.

Below is a summary of two representative models:

| Model | Measurement Range | Accuracy | Key Features |

|---|---|---|---|

| CONTURA | X: 700–1200 mm, Y: 700–2400 mm, Z: 600–1000 mm | 1.4 + L/350 µm | Bridge-type, multiple probe options, flexible software |

| PRISMO Ultra | Various configurations | 0.5 µm + L/500 | Ultra-high precision, air bearings, damped granite bed |

Faro CMMs, particularly the portable FaroArms and Laser Trackers, offer a unique combination of flexibility, ease of use, and cost efficiency. They are highly suitable for on-site inspections, reverse engineering, and alignment tasks. Faro’s devices are typically lightweight and ergonomically designed, allowing for single-operator handling and rapid setup in diverse environments, including manufacturing floors, construction sites, and even outdoors.

These devices use advanced laser and optical technologies, providing contact and non-contact measurement capabilities. Faro’s proprietary software—CAM2 and SCENE—enables real-time data visualization, automatic feature recognition, and seamless integration with CAD models. Many models also support wireless connectivity and battery-powered operation, allowing for true portability without sacrificing accuracy. With features such as interchangeable probe kits, multi-axis flexibility, and global positioning compatibility, Faro CMMs offer unmatched versatility for field applications.

Representative models from Faro’s portfolio include:

| Model | Measurement Range | Accuracy | Special Features |

|---|---|---|---|

| Gage Max | 1.2 m working volume | ±0.018 mm | Compact arm, 6-axis, fast setup, ideal for benchtop inspection |

| FARO ARM 8-Axis | Up to 4 m (depending on arm length) | ±0.029 mm (for longer arms) | Rotating platform, CAD-to-part inspection, reverse engineering support |

While both brands offer CMM solutions for quality assurance, their approaches and strengths differ considerably. Faro emphasizes portability and field usability, making their systems ideal for flexible deployment in a variety of environments. Their articulated arms are lightweight, easy to transport, and quick to set up, making them well-suited for on-site or in-situ inspections. In contrast, Zeiss systems are typically stationary and require more controlled settings, such as metrology labs, where environmental stability supports their high-precision capabilities.

The measurement approach also varies. Zeiss utilizes traditional bridge and gantry designs equipped with advanced sensors and scanning modules, making them suitable for high-volume production and precision tasks. Faro employs encoder-based articulated arms that allow for freeform inspection and greater physical maneuverability, especially for large or complex parts.

Software is another differentiator. Zeiss’s CALYPSO offers robust parametric programming, automation tools, and CAD integration, but has a steeper learning curve. Meanwhile, Faro’s CAM2 is designed for usability and quick deployment, focusing on real-time inspection and straightforward CAD comparison.

In terms of precision, Zeiss generally leads with superior measurement accuracy, which is crucial for applications with tight tolerance requirements. Faro systems, while slightly less precise, offer sufficient accuracy for many industrial tasks and compensate with their enhanced mobility and operational convenience.

Finally, setup requirements highlight their core differences. Faro systems can be installed and operated in virtually any environment with minimal preparation. Zeiss machines often demand a dedicated, climate-controlled space and professional installation to maintain their full potential.

Zeiss suits companies needing extremely high-precision measurements and robust automation—such as aerospace manufacturers, automotive OEMs, and medical device producers. Their solutions are ideal for centralized quality labs with skilled metrology teams.

Faro is an excellent fit for manufacturers needing flexibility and portability—such as job shops, maintenance teams, and companies handling large or irregular parts. It’s also popular in reverse engineering and digital twin applications.

Zeiss and Faro each serve vital roles in modern metrology. Zeiss emphasizes ultra-precise measurement and robust automation, while Faro prioritizes flexibility, mobility, and ease of use. Choosing between them depends on the specific measurement environment, required precision, and operational workflows. Both brands offer reliable, high-performance systems that enhance manufacturing quality and consistency.