Coordinate Measuring Machines (CMMs) are vital tools in modern manufacturing, enabling highly accurate dimensional inspection for parts and assemblies. Mitutoyo and Tokyo Seimitsu are two of Japan’s most prominent CMM manufacturers, each offering advanced metrology solutions. This article compares the two companies' offerings—highlighting both similarities and differences—to help users make informed decisions based on their specific inspection needs.

Mitutoyo, a global leader in precision measuring instruments, provides a broad lineup of CMMs suitable for shop-floor and laboratory environments alike. Known for reliability and ease of use, Mitutoyo’s CMMs integrate seamlessly into diverse production workflows. They support a variety of sensors, including contact and non-contact probes, to accommodate a wide range of inspection requirements.

One of Mitutoyo’s key differentiators is its proprietary software platform, MCOSMOS. This modular system offers solutions for everything from basic inspection to advanced scanning and analysis. MCOSMOS integrates CAD models, supports offline programming, and allows for automated inspection routines. In addition, Mitutoyo machines often feature compact footprints and robust structural designs, enabling them to perform well in environments with limited space or temperature fluctuations.

| Model | Measurement Range | Accuracy | Special Features |

|---|---|---|---|

| CRYSTA-Plus M | 710 x 1000 x 660 mm | ±1.7 μm | High-performance bridge CMM, MCOSMOS compatible, touch probe supported |

| MiSTAR 555 | 570 x 500 x 500 mm | ±2.2 μm | Designed for shop-floor use, vibration-resistant, high-speed measurement |

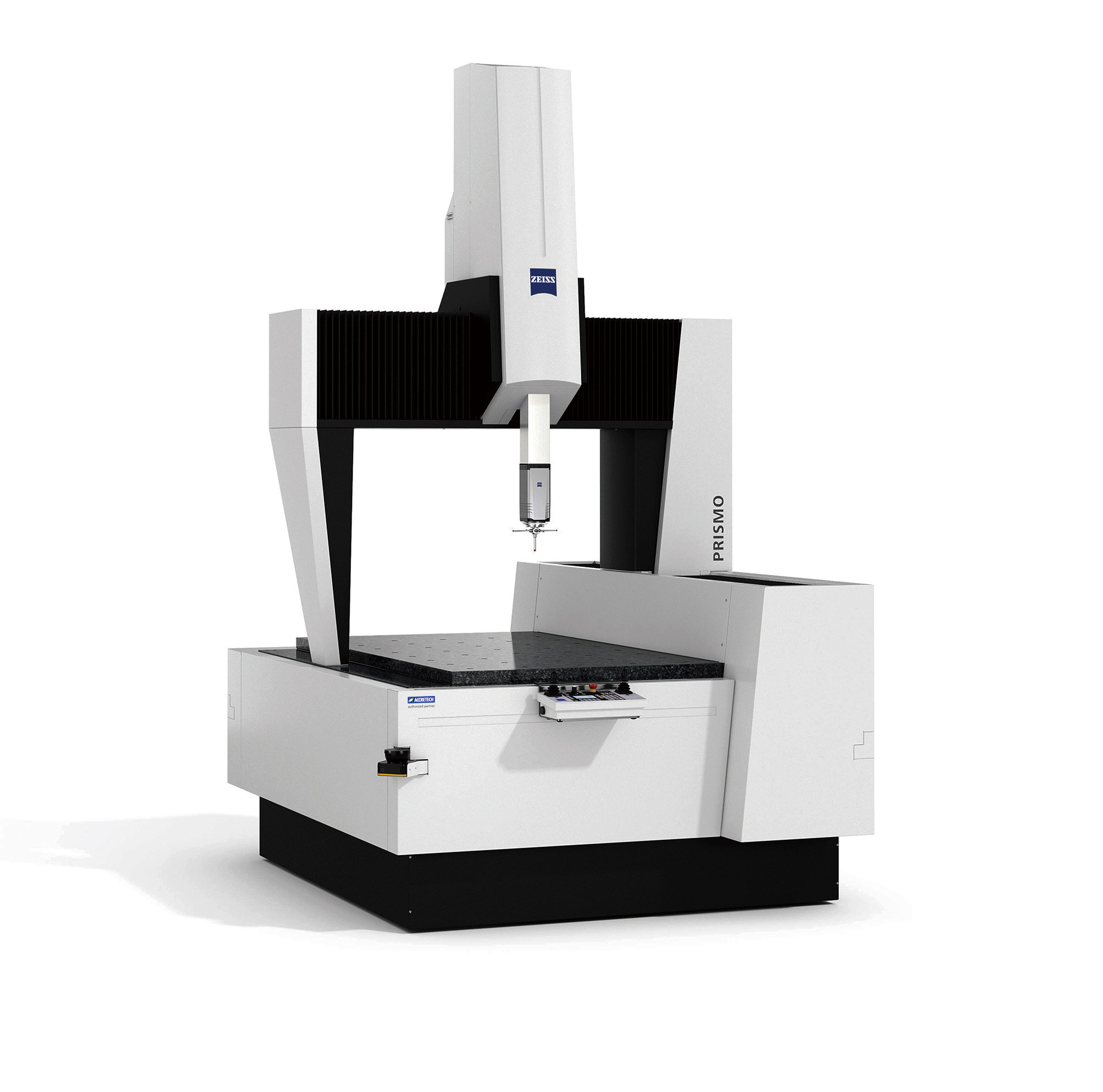

Tokyo Seimitsu, operating under the ACCRETECH brand, is a respected player in the metrology field, especially in Japan and Asia. Through a strategic partnership with Zeiss, Tokyo Seimitsu distributes high-precision CMMs that combine robust mechanical design with state-of-the-art sensor technology. These machines are built for environments that demand ultra-high accuracy, such as semiconductor, aerospace, and medical industries.

Their machines are known for structural rigidity, thermal stability, and compatibility with Zeiss’s CALYPSO software. This software allows for detailed parametric inspection, high-level customization, and powerful data management. Tokyo Seimitsu also emphasizes vibration isolation and cleanroom-ready construction, enabling consistent results even in the most demanding applications.

| Model | Measurement Range | Accuracy | Special Features |

|---|---|---|---|

| ZEISS XENOS | 850 x 1200 x 1000 mm | ±0.3 μm | Ultra-high accuracy, vibration isolation, air bearings |

| ZEISS PRISMO | 700 mm to 3000 mm (configurable) | ±0.9 μm | Multi-sensor compatibility, thermal compensation, high-speed scanning |

While both Mitutoyo and Tokyo Seimitsu produce high-performance coordinate measuring machines, they adopt different design philosophies and cater to distinct user priorities. Mitutoyo focuses on creating accessible, flexible systems suitable for a broad range of users and environments. Tokyo Seimitsu, in partnership with Zeiss, targets users who require extreme precision and advanced metrology tools for highly regulated industries.

In terms of accuracy, Tokyo Seimitsu clearly leads, offering sub-micron and even nanometer-level repeatability in models like the ZEISS XENOS. These machines are engineered for scientific-grade inspection environments, cleanrooms, and high-end production. Mitutoyo, while not aiming for such extremes, delivers excellent accuracy for general industrial applications and balances performance with durability and cost-efficiency. Their systems are built to withstand the rigors of everyday use and provide long-term value across varied manufacturing sectors.

Sensor options also reflect this divide. Mitutoyo supports tactile probes, laser sensors, and other accessories suitable for both routine and complex tasks. This flexibility allows manufacturers to tailor their systems to specific parts or inspection workflows. Tokyo Seimitsu CMMs benefit from Zeiss’s advanced sensor ecosystem, including scanning probes and non-contact options tailored for intricate geometries and delicate materials, providing high fidelity in measurements that are critical to industries like aerospace and medical device manufacturing.

Software is another major distinction. Mitutoyo’s MCOSMOS platform is praised for its user-friendliness, flexibility, and strong CAD integration. It is well-suited to manufacturers seeking a scalable solution that can grow with their needs. Conversely, Tokyo Seimitsu’s use of Zeiss’s CALYPSO software offers deeper parametric programming capabilities, ideal for companies with rigorous inspection protocols and high documentation standards. While CALYPSO may have a steeper learning curve, its capabilities shine in complex inspection environments requiring high traceability and repeatability.

Physical design considerations further differentiate the two. Mitutoyo offers rugged, compact systems designed to thrive even in semi-controlled environments such as shop floors. Their MiSTAR 555, for example, is vibration-resistant and suitable for near-line inspection. Tokyo Seimitsu emphasizes structural integrity, thermal insulation, and vibration control—making their systems optimal for climate-controlled metrology labs. The physical robustness of Mitutoyo makes it attractive for manufacturers that require dependable performance without the need for a highly controlled environment.

Support services also vary. Mitutoyo provides a global network of training and maintenance services, helping international manufacturers standardize quality control across borders. Their emphasis on customer education and system optimization ensures that users can quickly become productive and self-reliant. Tokyo Seimitsu, meanwhile, excels in localized, high-touch support within Japan and nearby regions, making them especially attractive to companies with domestic operations prioritizing response speed and communication quality. Their long-term support contracts and technician availability add peace of mind for businesses operating in precision-driven sectors.

Mitutoyo CMMs are ideal for manufacturers looking for durable, easy-to-use, and cost-effective solutions. They suit operations that require good accuracy, rapid inspection, and flexible deployment across multiple production environments. Their intuitive software and solid support make them accessible even for teams new to coordinate metrology. Manufacturers involved in automotive, general machinery, or consumer electronics often benefit from Mitutoyo's scalable offerings, which balance performance with affordability. The company’s global support infrastructure also makes it a reliable choice for multi-site operations seeking unified measurement strategies.

Tokyo Seimitsu CMMs are designed for precision-critical industries where tolerance is measured in microns or less. Companies in aerospace, medical, semiconductor, or research sectors will benefit most from their unmatched accuracy, cleanroom compatibility, and robust performance under controlled conditions. Their deep integration with Zeiss technologies positions them as a preferred choice for companies that require ultra-consistent measurements, complete traceability, and advanced analysis capabilities. Additionally, Tokyo Seimitsu's localized support ensures that highly specialized users have the resources and technical assistance needed to optimize their operations with confidence.

Mitutoyo and Tokyo Seimitsu offer distinct value propositions in the world of coordinate measuring machines. Mitutoyo emphasizes versatility, affordability, and ease of use, while Tokyo Seimitsu prioritizes ultimate precision, environmental stability, and integration with advanced Zeiss technologies. The best choice depends on your operational goals: broad usability and scalability or elite-level precision and specialization. Both brands play vital roles in advancing modern quality assurance across global industries.