There are various types of CMMs, such as gantry-, arm-, and handheld-type machines, each with different precision levels. Among them, gantry-types are particularly known for their high accuracy. In general, accuracy is around 1 μm with a contact probe and approximately 10 μm when using a non-contact measurement method. However, in recent years, models capable of measurements with precision up to 0.1 μm have been introduced.

The advantages of high-accuracy CMMs lie in their ability to enable higher-level reverse engineering and quality control. However, as the functionality and accuracy increase, the cost of the equipment also tends to rise significantly. Therefore, it is crucial to assess the required measurement accuracy against the cost benefits before selecting a machine.

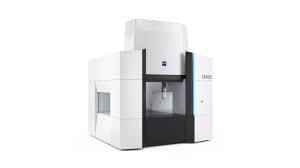

Below, we showcase some high-accuracy CMMs. If you are considering the adoption of a high-accuracy measurement device, be sure to check these out.

The ZEISS XENOS maintains high accuracy by using its unique Zerodur scale, eliminating temperature correction uncertainties. Additionally, it uses silicon carbide ceramics for the main structural components. Compared to alumina ceramics, silicon carbide ceramics boast low expansion, high rigidity, and are also lightweight, which contribues to the high accuracy of the ZEISS XENOS.

A notable feature of the ZEISS XENOS is its virtual center drive, which is not present in conventional measuring machines. It employs a linear drive structure for all axes, and the newly developed Y-axis dual-drive structure (virtual center drive) optimizes left and right drive control. This enables exceptionally high repeatability. ZEISS XENOS is recommended for environments where precision is crucial, including research institutions, the aerospace industry, and optical equipment manufacturing.

The LEGEX Series is a CNC CMM that boasts world-class precision, achieving ultra-high accuracy by eliminating error factors. The main base unit features high rigidity and high damping properties, ensuring geometric motion accuracy by minimizing deformation due to load variations through a sealed structure and finite element method (FEM) structural analysis simulation. For position detection, it utilizes a length measuring unit combining ultra-high precision crystallized glass scales with a thermal expansion coefficient ≒ 0 and high-resolution reflective linear encoders, realizing extremely high position detection capability and ultra-high precision machine control.

For environments requiring a constant temperature chamber for ultra-high precision equipment, the LEGEX Series provides guaranteed accuracy over a wide range of temperature conditions through its temperature compensation function. Various options, including probes and data processing units, are available to accommodate different types of workpieces.

The Leitz Infinity is a high-end model that further enhances the speed and precision of the PMM-C model, known for its accuracy. Based on Hexagon Metrology's technology and expertise, the CMMs achieves uncompromisingly accurate measurements. It is commonly used for measuring parts with extremely tight tolerances and products that demand high accuracy. The Leitz Infinity can perform measurements in the deep parts of components, on fragile surfaces, and for products with high precision requirements, including lens (glass, plastic) surfaces and contour measurements.

Source: KEYENCE Website(https://www.keyence.com/products/measure-sys/cmm/xm/index_pr.jsp)

This CMM has a caliper-like feel, enabling even beginners to perform high-precision measurements. It can be carried without the need for temperature control, allowing for immediate measurements at any desired location and time. As it doesn't require a large installation space, it's a CMM with a low entry barrier.

Source: Carl Zeiss Website(https://www.zeiss.com/metrology/products/systems/cmm.html)

Utilizing linear drive on all axes, this CMM boasts high precision with a maximum permissible length measurement error of 0.3+L/1000μm, repeatability of ±0.2μm, and resolution of 0.001μm. The reduced occurrence of errors allows for a decrease in the need for remeasurement.

Source: Mitutoyo Website(https://www.mitutoyo.com/products/coordinate-measuring-machines/)

A CNC CMM that was first developed in 1976.

It features applications that respond to the demand for "Smart Factories" by allowing monitoring of operational status and maintenance management of the machine through the network.

Reasons for Selection