In today’s highly competitive manufacturing landscape, the demand for precision, efficiency, and automation is growing rapidly. Coordinate Measuring Machines (CMMs) play a vital role in ensuring that manufactured parts conform to strict specifications. Among the leading CMM manufacturers are KEYENCE and Zeiss, each offering unique advantages. While KEYENCE emphasizes user-friendliness and operational speed, Zeiss is known for its high-end precision and extensive configurability. This article provides an in-depth comparison between their CMM offerings, exploring features, specifications, and suitability for different use cases.

KEYENCE has redefined how coordinate measuring is performed in production environments. The company’s flagship series — such as the XM and WM — are designed for ease of use and portability. These CMMs require no specialized metrology experience, thanks to intuitive interfaces and automated report generation.

The KEYENCE XM Series, for instance, uses a handheld probe guided by an integrated camera system. Operators can measure complex parts from multiple angles without fixtures or jigs. The system offers immediate feedback and stores 3D CAD comparison data, which is highly beneficial for inline inspections.

KEYENCE’s systems are optimized for speed and agility. They are especially effective on the shop floor where rapid inspection is crucial, minimizing downtime and bottlenecks.

Below is a summary of two representative models:

| Model | Measurement Range | Key Features |

|---|---|---|

| XM-5000 Series | ~600 mm (XYZ) | Portable, handheld probe, CAD comparison |

| WM Series | Up to 15 m | Large part measurement, wireless, shop floor use |

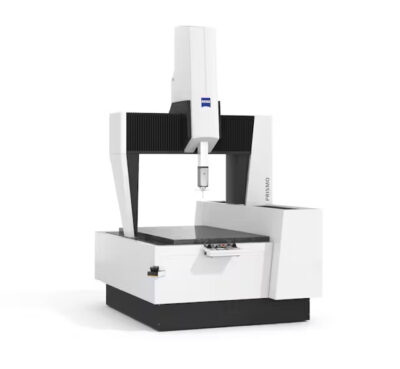

Zeiss has long been synonymous with metrology excellence. The company offers a broad range of high-precision CMMs, from bridge-type machines for lab-grade accuracy to gantry systems and optical scanners. Their machines are trusted in industries like aerospace, automotive, medical device manufacturing, and research.

A major strength lies in the flexibility of their sensor technologies. Users can switch between tactile scanning, optical probing, and even computed tomography (CT) scanning depending on the application.

Zeiss also excels in software. Their CALYPSO software integrates seamlessly with CAD systems, offering powerful automation and advanced error mapping. Training is required, but the return on precision and capabilities is immense.

Below is a summary of two representative models:

| Model | Measurement Range | Key Features |

|---|---|---|

| CONTURA | X: 700–1200 mm, Y: 700–2400 mm, Z: 600–1000 mm | Bridge-type, multiple probe options, flexible software |

| PRISMO Ultra | Various configurations | Ultra-high precision, air bearings, damped granite bed |

Although both companies provide advanced CMM solutions, their approach differs significantly. Below is a side-by-side comparison to illustrate:

| Aspect | KEYENCE | Zeiss |

|---|---|---|

| Ease of Use | Very high – no specialized training required | Moderate – requires metrology knowledge |

| Precision | Good for general manufacturing | Excellent – suitable for aerospace, medical |

| Portability | Highly portable | Stationary lab setups |

| Software Integration | Basic CAD integration | Advanced CAD/CAM/PLM compatibility |

| Sensor Types | Handheld, contact and 3D scanning | Multi-sensor systems including tactile, CT |

| Ideal Application | On-the-floor inspection | High-end quality assurance, R&D |

Your ideal CMM depends on the context and complexity of your manufacturing process:

Whether you choose Keyence or Zeiss, both offer world-class CMM systems with unique advantages. Keyence revolutionizes on-site measurement with its intuitive, portable systems, making it ideal for companies seeking agility and ease of operation. Zeiss, meanwhile, remains the gold standard in dimensional measurement, delivering unparalleled setup flexibility.

The right CMM depends not only on accuracy but also on workflow, environment, user skill level, and budget. Careful consideration of these factors will ensure your investment meets both current and future measurement needs.