Here, we introduce the key points of Hexagon's representative CMMs. Additionally, the article summarizes the company's characteristics and the research and initiatives the company has been undertaking.

The ALPHA model is a gantry-type CMs capable of inspecting and measuring large cast iron and machined parts. There are two available types: Classic and Performance. The Classic type is versatile, equipped with an optical scanning sensor, enabling digitization of millions of data points. The Performance type is designed to be less affected by temperature, thanks to its linear temperature compensation function.

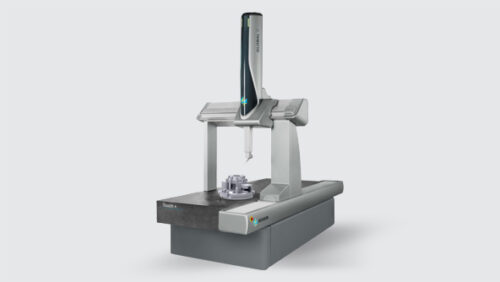

The GLOBAL series comprises all-purpose bridge-type CMMs suitable for various applications. GLOBAL Touch+ focuses on measuring efficiency, GLOBAL Scan+ employs advanced tactile scanning technology, GLOBAL Optics is equipped with high-resolution optical sensors, and GLOBAL Speed comes with a laser scanning sensor. A multi-sensor feature enables the series to answer diverse needs. The design prioritizes safety and reliability, with features like automatic power-off and automatic deceleration upon entry into the work area. Options for machine status monitoring and real-time information monitoring are also available.

The Leitz Infinity is Hexagon's top-class ultra-high-accuracy CMM. Iy was developed for difficult measurement tasks and for highest precision quality and process management. Features like dynamic single-point probing and continuous high-speed scanning (HSS) enable rapid processing, suitable even for complex shapes like cylindrical gears.

This is a robust shop-floor CMM designed for harsh manufacturing environments. With an excellent temperature compensation function, it operates in environments ranging from 15° to 40°. The measuring stage uses granite, ensuring continued measurements even in tough conditions. It's standalone, allowing for easy relocation on-site.

Hexagon is a technology-driven global company established in Sweden in 2000. Starting with digital reality solutions, it has continued its journey towards smart digital reality through building sensor software solutions.

Currently, its fundamental policy is to create sustainable value through its production and employee ecosystem. To achieve this, the company provides CMMs and various information management systems that enhance efficiency, productivity, and quality.

While its headquarters are in Stockholm, Sweden, Hexagon has a global presence with bases and partner companies worldwide. This strength allows it to understand diverse needs in production sites and leverage that knowledge in product development. The company is also envolved with agriculture optimization and offers corporate engineering solutions.

Regarding digitalization solutions, it has expanded its focus to industries like aerospace, automotive, architecture and construction, chemistry, infrastructure, and energy, proposing problem-solving approaches with "autonomy in processes" as a key concept.

Hexagon offers a wide range of CMMs, from large bridge- and arm-types to machines that are tailored to the sizes and shapes of the objects being measured. These machines can be expanded later on.

More than just developing and selling measuring machines, Hexagon proposes solutions aimed at improving production efficiency and cost reduction. Its approach is purpose-driven, avoiding unnecessary efforts. The company also has a system in place for upgrading CMMs and providing repair products, ensuring reliability.

Hexagon, as a company offering various solutions including digitalization for enterprises, has a global reach. In this sense, it could be said that it's more of a systems consultant company than a measuring machine manufacturer.

Therefore, Hexagon is recommended for companies who are considering not only the introduction of CMMs, but also overall efficiency improvement and problem solving. To facilitate swift introduction of measuring machines, it's advisable to organize your company's challenges beforehand.

Source: KEYENCE Website(https://www.keyence.com/products/measure-sys/cmm/xm/index_pr.jsp)

This CMM has a caliper-like feel, enabling even beginners to perform high-precision measurements. It can be carried without the need for temperature control, allowing for immediate measurements at any desired location and time. As it doesn't require a large installation space, it's a CMM with a low entry barrier.

Source: Carl Zeiss Website(https://www.zeiss.com/metrology/products/systems/cmm.html)

Utilizing linear drive on all axes, this CMM boasts high precision with a maximum permissible length measurement error of 0.3+L/1000μm, repeatability of ±0.2μm, and resolution of 0.001μm. The reduced occurrence of errors allows for a decrease in the need for remeasurement.

Source: Mitutoyo Website(https://www.mitutoyo.com/products/coordinate-measuring-machines/)

A CNC CMM that was first developed in 1976.

It features applications that respond to the demand for "Smart Factories" by allowing monitoring of operational status and maintenance management of the machine through the network.

Reasons for Selection