Coordinate Measuring Machines (CMMs) are essential tools in precision manufacturing, ensuring quality control and dimensional accuracy. Among the leading providers in this space, Hexagon and Coord 3 offer compelling solutions with different strengths. This article explores how each brand approaches design, technology, and usability to help users identify the most suitable CMM for their specific inspection needs.

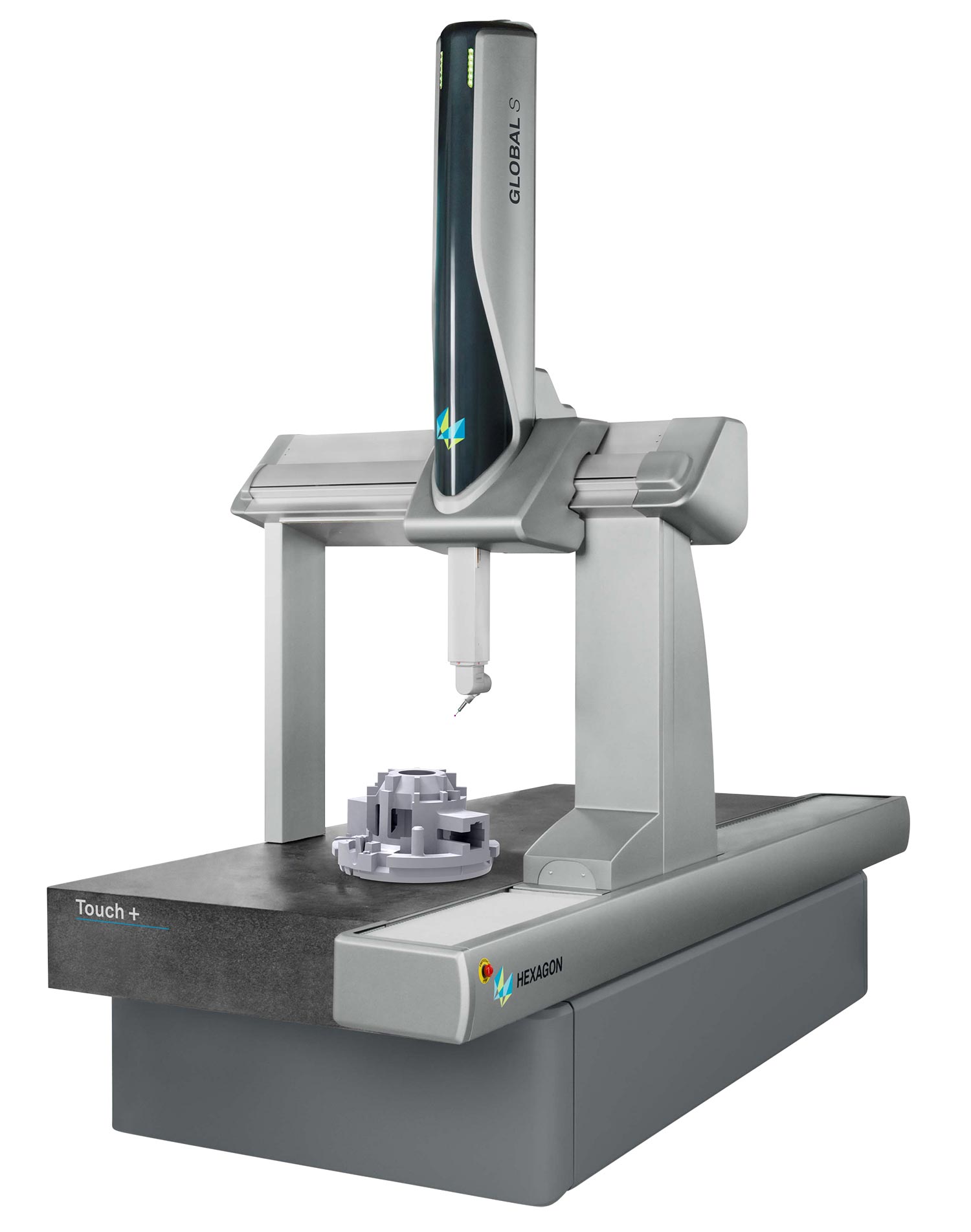

Hexagon is a global leader in metrology with a reputation for high-performance systems tailored for advanced industrial applications. Their CMMs come in bridge, gantry, and horizontal-arm designs to accommodate different part sizes and inspection settings. Hexagon’s hallmark is sensor diversity, supporting tactile probes, laser scanners, and vision systems.

The company’s proprietary PC-DMIS software is another standout feature. It enables seamless CAD integration, automated inspection routines, and real-time reporting. Models such as GLOBAL Touch+ introduce intuitive touch-screen controls and improved ergonomics, making them particularly effective for shop-floor integration.

| Model | Measurement Range | Accuracy | Special Features |

|---|---|---|---|

| ALPHA | 1200 x 1500 x 1000 mm (varies) | ±1.5 μm | High accuracy, automation-ready, tactile sensor compatible |

| GLOBAL Touch+ | Configurable | ±2 μm | Touchscreen UI, CAD integration, PC-DMIS support |

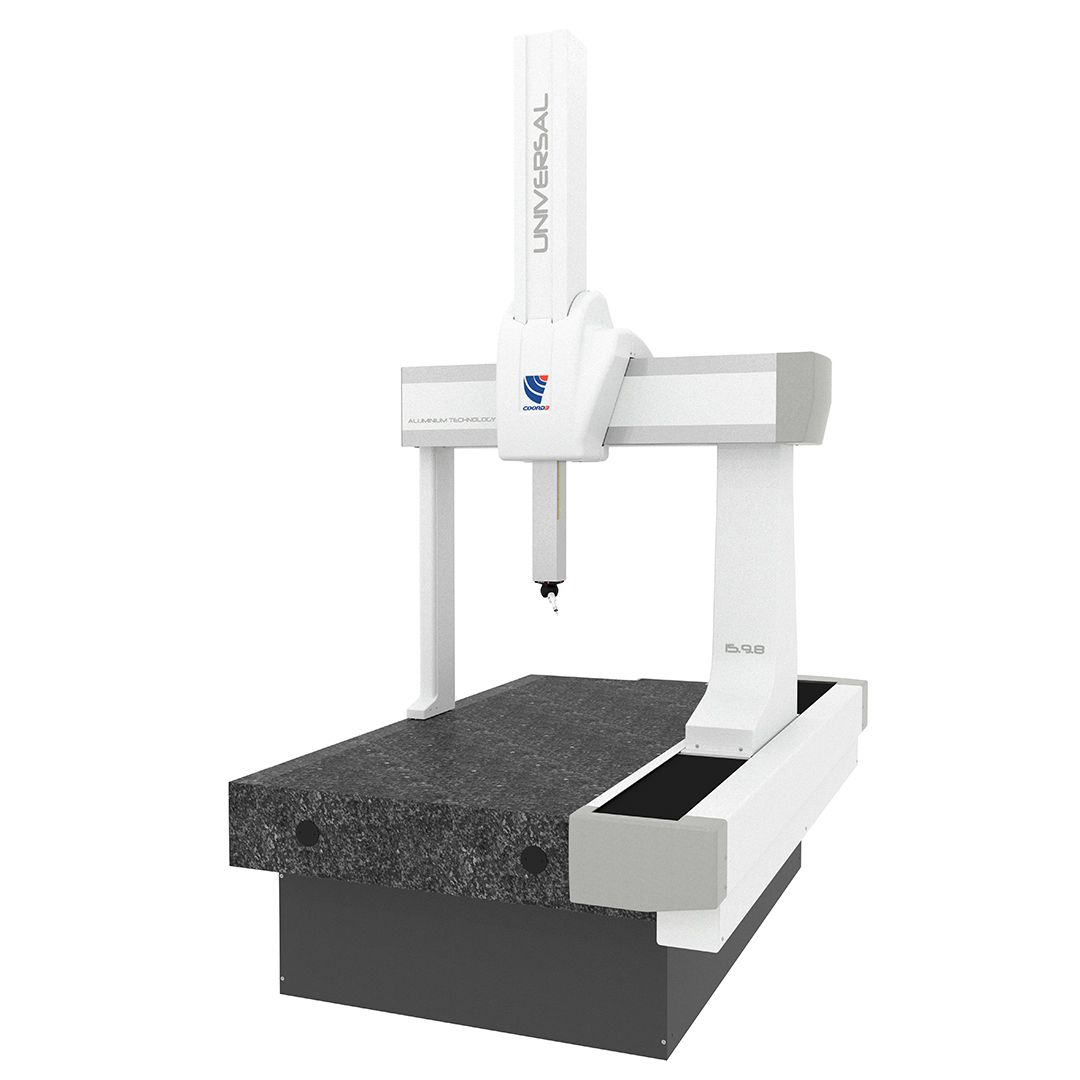

Coord 3 is an Italian manufacturer with a strong foothold in both standard and heavy-duty CMM markets. Their machines range from compact bridge-type units to expansive gantry systems suitable for large aerospace or automotive parts. Coord 3 emphasizes mechanical rigidity and environmental resilience, with robust granite structures and thermal compensation systems.

The systems are compatible with mainstream metrology software like PC-DMIS and support tactile and optical probes. This allows seamless integration into established workflows while offering flexibility for multi-sensor configurations. Their gantry-type MCT PLUS is particularly favored for inspecting large-scale components with high repeatability.

| Model | Measurement Range | Accuracy | Key Features |

|---|---|---|---|

| Ares | 500x500x400 mm to 2000x1500x1000 mm | ±2 μm | High rigidity, modularity, multi-sensor support |

| MCT PLUS | 3000x2000x1500 mm and above | ±2.5 μm | Large-scale gantry system, thermal stability, aerospace-ready |

Hexagon and Coord 3 cater to similar industrial needs but offer distinct advantages. Hexagon emphasizes global scalability, automation readiness, and user-focused software ecosystems. Their machines, equipped with PC-DMIS, are intuitive and adaptable, making them well-suited for manufacturers looking to standardize quality across multiple locations.

Coord 3, while less globally pervasive, excels in mechanical stability and large-format measurement. Their machines are ideal for industries where robustness and scale matter more than interface innovation. The use of PC-DMIS by both brands ensures interoperability, but Coord 3’s strength lies in its customizability and rugged design rather than UI enhancements.

Sensor variety is broad for both brands, although Hexagon leads in terms of seamless multi-sensor integration and visualization. Coord 3’s modular architecture supports upgrades over time, making it attractive for evolving production lines.

Support structures also differ: Hexagon boasts an extensive global service network with remote diagnostics and multilingual training. Coord 3 offers more localized support, often through regional distributors, with a reputation for responsive technical service in Europe and select global markets.

Hexagon is ideal for large-scale manufacturers requiring fast deployment, automation, and international consistency. Their systems are perfect for production lines where software usability, multi-site support, and flexible sensor integration are critical.

Coord 3 suits users needing rigid, heavy-duty equipment that can handle large parts and tough environments. Their gantry systems and mechanical precision make them a go-to option for aerospace, energy, and heavy manufacturing sectors.

Hexagon and Coord 3 both offer robust, capable CMM platforms. Hexagon shines in software, user experience, and worldwide support, while Coord 3 offers strength in mechanical integrity, modularity, and value for custom inspection needs. Choosing the right brand depends on priorities such as part size, inspection complexity, software integration, and desired support level.