Source: Aberlink website

Source: Aberlink website

(https://www.aberlink.com/products/coordinate-measuring-machines/)

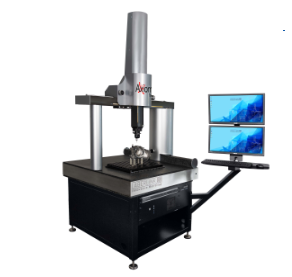

Axiom too represents the culmination of Aberlink's 20 years of continuous learning and improvement. It's a sophisticated CMM designed to inspect small to medium-sized parts weighing up to 500 kg. With its all-aluminum bridge construction, temperature control becomes critical. However, Axiom too quickly adapts to room temperature and maintains stability without compromising operational efficiency. Additionally, it offers the flexibility to be easily upgraded from manual to CNC at any time.

Source: Aberlink website

Source: Aberlink website

(https://www.aberlink.com/products/coordinate-measuring-machines/)

Designed for medium to large parts with a maximum load capacity of 1000 kg, the Horizon CMM represents a new pinnacle of design and innovation. Its standout feature is the frictionless linear drive, which enables high-speed operation while ensuring remarkably smooth performance. Utilizing linear motors, which are non-contact and devoid of wearing parts, this CMM drive enhances reliability and reduces maintenance requirements significantly. Moreover, its fast, smooth, and quiet operation makes it particularly well-suited for contact scanning tasks. Notably, the accuracy specification for the Horizon CMM is less than 2 microns for the first term.

Source: Aberlink website

Source: Aberlink website

(https://www.aberlink.com/products/coordinate-measuring-machines/)

Fulcrum stands out as an innovative, manual, and portable CMM, offering unparalleled ease of learning and operation for inspecting small parts directly on the shop floor. Its three-axis design is tailored for job site convenience, featuring a compact and portable build that enables usage wherever needed. Despite its manual operation, Fulcrum boasts a user-friendly interface while retaining full functionality. Thanks to its intuitive software and innovative design, Fulcrum delivers measurement results within minutes of activation, requiring no prior operating experience. Furthermore, Fulcrum achieves a volumetric accuracy of 5 microns at 40 nanometers, ensuring precise and reliable measurements.

Aberlink was founded in 1993 by mechanical engineers Marcus Ealse and Gavin Bailey, and has since emerged as a notable success story in England. Through a process of trial and error, they have conducted extensive research and invested in both human and physical resources, such as hiring skilled personnel and relocating and expanding facilities. Consequently, Aberlink has amassed numerous patents and intellectual property, which have been integrated into their products to enhance quality, precision, and durability. Today, their technology, quality, and user-friendly interface are globally recognized, leading to the expansion of their business operations.

Aberlink's primary objective is to offer cutting-edge technology products at competitive prices. To realize this vision, Aberlink strategically focuses on minimizing external expenses and operates as a fully integrated company, spanning from production to sales and post-market services. This approach enables Aberlink to gain comprehensive insights into the manufacturing process, develop efficient manufacturing designs, and deliver straightforward, dependable products at unmatched prices, free from additional expenses. Moreover, Aberlink distinguishes itself as the sole major metrology manufacturer to provide complimentary software updates and to supply machines without requiring annual software maintenance contracts or subscriptions. This commitment results in a remarkably low cost of ownership and facilitates the swiftest return on investment possible.

Aberlink offers a comprehensive range of CMM products, available in 23 standard sizes and offered in both CNC and manual variants. These CMMs are capable of accurately measuring components ranging from the smallest parts to those exceeding 3 meters in length and weighing up to 6 tons. We provide a diverse selection of probing and non-contact measurement options, along with on-machine fixture choices, catering to various measurement needs. This extensive range enables Aberlink to deliver high-quality CMMs suitable for every application and budget. Moreover, Aberlink's meticulous quality standards guarantee a service life exceeding 20 years, even in challenging workplace environments. Additionally, each product is designed to be upgradable, ensuring it remains relevant and effective over time, thereby never becoming obsolete.

Aberlink manufactures products tailored for professionals operating in safety-critical sectors where precision is paramount, including aerospace, automotive, electronics, petroleum, and medical industries. To ensure adherence to rigorous quality standards, all Aberlink products undergo meticulous in-process checks and undergo a comprehensive final inspection. This commitment to stringent quality control makes Aberlink the ideal choice for companies seeking products manufactured under rigorous quality standards while also offering a cost-effective investment solution.

Source: KEYENCE Website(https://www.keyence.com/products/measure-sys/cmm/xm/index_pr.jsp)

This CMM has a caliper-like feel, enabling even beginners to perform high-precision measurements. It can be carried without the need for temperature control, allowing for immediate measurements at any desired location and time. As it doesn't require a large installation space, it's a CMM with a low entry barrier.

Source: Carl Zeiss Website(https://www.zeiss.com/metrology/products/systems/cmm.html)

Utilizing linear drive on all axes, this CMM boasts high precision with a maximum permissible length measurement error of 0.3+L/1000μm, repeatability of ±0.2μm, and resolution of 0.001μm. The reduced occurrence of errors allows for a decrease in the need for remeasurement.

Source: Mitutoyo Website(https://www.mitutoyo.com/products/coordinate-measuring-machines/)

A CNC CMM that was first developed in 1976.

It features applications that respond to the demand for "Smart Factories" by allowing monitoring of operational status and maintenance management of the machine through the network.

Reasons for Selection