On this page, we have compiled the features and functionalities of Hexagon's bridge-type CMMs, specifically the GLOBAL series. You can also check application examples and use cases of the GLOBAL series.

Hexagon offers a wide range of CMMs for various dimensional inspection tasks. Bridge CMMs are designed to measure the dimensions of products placed on a table. There are different types of Bridge CMMs, from entry-level to ultra-high precision models.

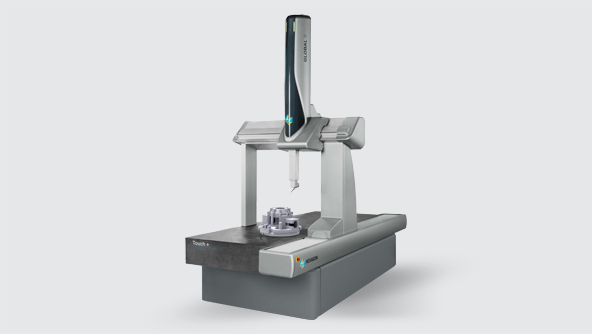

Developed as bridge-type CMM products, the GLOBAL Series comprises four types. GLOBAL Touch+ prioritizes measurement efficiency, GLOBAL Scan+ employs advanced tactile scanning, GLOBAL Optics features a high-resolution optical sensor, and GLOBAL Speed is equipped with a laser scanning sensor, each offering distinct characteristics.

The development concept of the GLOBAL Series places a strong emphasis on application-centric design. On-site, CMMs have to correspond to diverse application needs, such as variations in product size, shapes ranging from simple to complex, and more.

To address these requirements, the Hexagon GLOBAL Series is equipped with multi-sensor functionality. On top of the basic features, optional functions can be added to address specific needs. This flexibility enables precise adaptation to subtle differences in requirements.

The GLOBAL Series is designed with a focus on long-term stability, reduction of measurement uncertainty, adaptability to harsh operation environemtns, and reliability. It allows for high precision, high-speed measurements while also ensuring a safe operating environment.

Features include automatic power-off during idle times, automatic deceleration when users or objects enter the work area, and additional options such as message lights for monitoring the machine's status and real-time monitoring of machine information.

One of the challenges that Hexagon can solve with the GLOBAL Touch+ (outfitted with a touch-trigger probe) is the measuring of complex part shapes. The GLOBAL Touch+ utilizes an electric indexable probe head, enabling single point tactile measurements.

Even for parts with intricate and varying dimensions, the key feature is the ability to conduct rapid inspections and measurements. Primary applications include mold components for plastic injection molding, machined mechanical parts, and hinge joints.

The GLOBAL Speed, equipped with a laser scanner, addresses the challenge of achieving high throughput in full surface measurement. The primary applications include E-Mobility hairpins, blades, and metal part measurements.

It can accurately measure the entire surface of components within point clouds without compromising throughput, even in applications involving freeform surfaces and multiple materials. This capability reduces the number of correction loops, optimizes processes, and contributes to minimizing defects and rework.

The Hexagon GLOBAL Series is characterized by its adaptability to various workplace conditions, offering flexibility in product types and options. Therefore, it is well-suited for situations where you may want to start with a measuring machine equipped with basic features and gradually expand.

Moreover, the emphasis on safety makes it suitable for environments where workers are not yet familiar with CMMs. If there are specific challenges in the workplace, Hexagon provides support in selecting products and options to address those challenges.

Source: KEYENCE Website(https://www.keyence.com/products/measure-sys/cmm/xm/index_pr.jsp)

This CMM has a caliper-like feel, enabling even beginners to perform high-precision measurements. It can be carried without the need for temperature control, allowing for immediate measurements at any desired location and time. As it doesn't require a large installation space, it's a CMM with a low entry barrier.

Source: Carl Zeiss Website(https://www.zeiss.com/metrology/products/systems/cmm.html)

Utilizing linear drive on all axes, this CMM boasts high precision with a maximum permissible length measurement error of 0.3+L/1000μm, repeatability of ±0.2μm, and resolution of 0.001μm. The reduced occurrence of errors allows for a decrease in the need for remeasurement.

Source: Mitutoyo Website(https://www.mitutoyo.com/products/coordinate-measuring-machines/)

A CNC CMM that was first developed in 1976.

It features applications that respond to the demand for "Smart Factories" by allowing monitoring of operational status and maintenance management of the machine through the network.

Reasons for Selection