Highlighting the key features of Hexagon's leading Coordinate Measuring Machines (CMMs), this article also provides an overview of the company's distinctive strengths and various research initiatives it has undertaken.

Source: Tokyo Seimitsu

Source: Tokyo Seimitsu

(https://www.accretech.com/jp/product/measuring/system/cmm/zeiss_xenos.html)

ZEISS XENOS uses innovative silicon carbide ceramics for its main structural components to achieve high precision. Unlike most CMMs, this model uses a linear drive structure for all axes. It also incorporates a newly developed Y-axis dual drive structure called a virtual center drive. These unique features ensure very high repeatability over the entire measurement range. To eliminate uncertainties in temperature compensation, the Zero-Dur scale, known for its zero expansion coefficient, has been used in the development of the ZEISS XENOS.

Source: Tokyo Seimitsu

Source: Tokyo Seimitsu

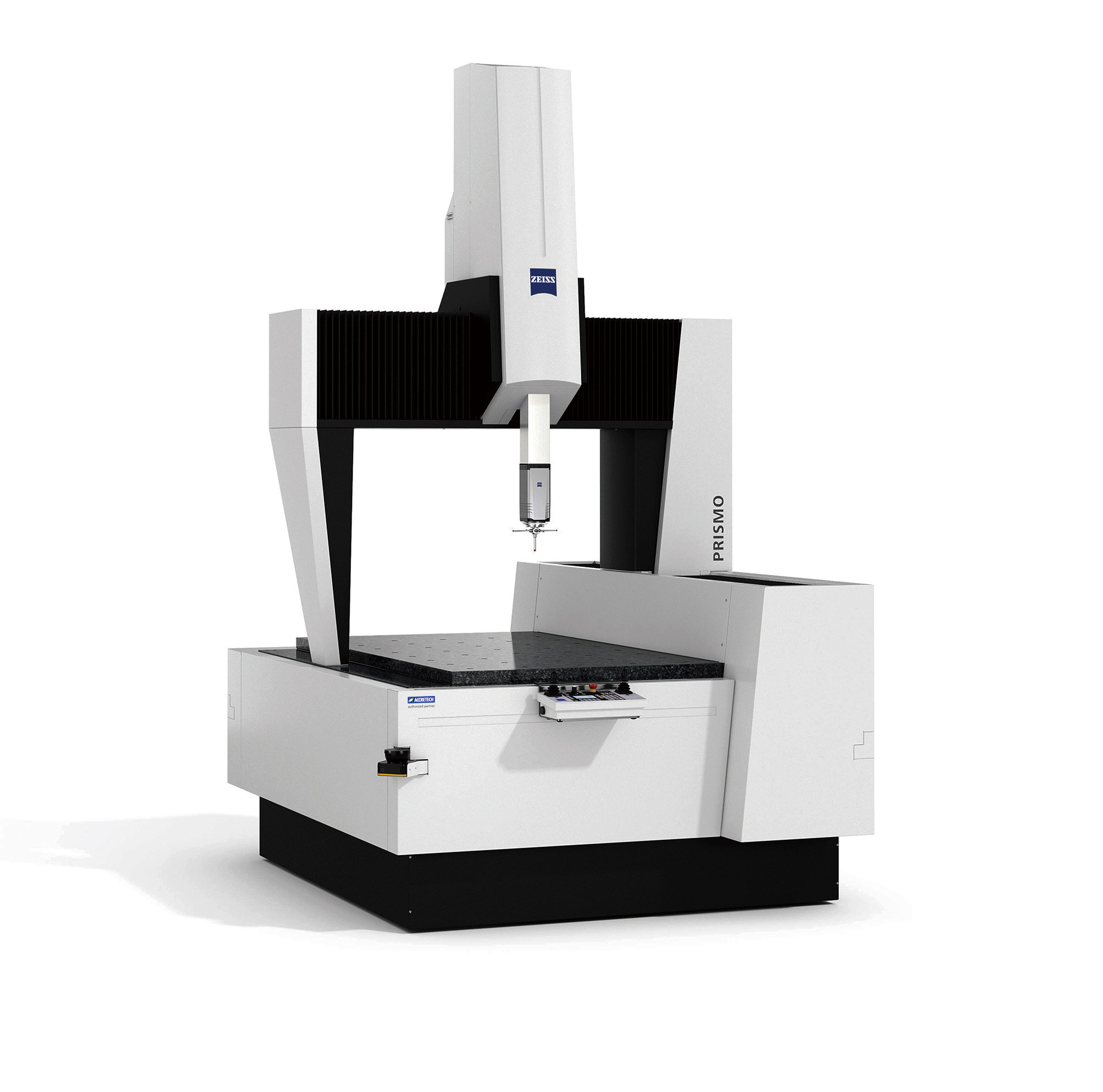

(https://www.accretech.com/jp/product/measuring/system/cmm/zeiss_prismo.html)

The ZEISS PRISMO is the flagship model of ZEISS coordinate measuring machines, boasting a guaranteed accuracy of E0, MPE = 0.9+L/350 μm. It is equipped with the VAST XT gold active scanning sensor, which maintains a constant measuring force and minimizes deflection, even during high-speed scanning, to ensure highly accurate measurements. Additionally, each axis guide is supported by air bearings from four directions (top, bottom, left, and right) to prevent twisting of the measuring machine during operation. This stable drive enables efficient, high-speed, and high-precision measurements.

Source: Tokyo Seimitsu

Source: Tokyo Seimitsu

(https://www.accretech.com/jp/product/measuring/system/cmm/zeiss_prismo_fortis.html)

The ZEISS PRISMO fortis, like the top-of-the-line ZEISS PRISMO ultra, is equipped with temperature sensors on both the front and back surfaces of the surface plate. This system can compensate for even the slightest distortion of the surface plate caused by temperature gradients. Additionally, the Zerodur scale, with its extremely low coefficient of thermal expansion, is installed to ensure a wide temperature range of guaranteed accuracy. This allows the machine to be used in production environments with harsh temperature conditions while maintaining high accuracy.

Founded in 1949, Tokyo Seimitsu is a precision equipment manufacturer that has established a noteworthy presence in two key fields: semiconductor manufacturing equipment and precision measuring instruments. With offices located globally, the company strives to meet the continually evolving needs of the manufacturing industry. Tokyo Seimitsu has developed technologies for precise measurement and processing, aiming for nano-level precision at 1/10,000th of the thickness of a hair. Through its manufacturing facilities worldwide, it aims to contribute to society in various fields.

Tokyo Seimitsu is known for its precision engineering. Its flagship product, the RONDCOM CREST roundness and cylindrical shape measuring instrument, features ultra-high precision that exceeds global standards. It also offers superior operability from the customer's point of view, such as automatic switching between roundness and surface roughness measurement.

The "Carl Zeiss Series" lineup of CMMs can meet a variety of customer needs. In addition, the company has sales offices in Japan and overseas to provide full support. To help customers make more effective use of CMMs, the company regularly holds training schools.

Tokyo Seimitsu offers a wide variety of CMMs with emphasis on accuracy. The company also provides comprehensive support through customer centers located around the world. In case of machine trouble at a factory, Tokyo Seimitsu responds promptly. Tokyo Seimitsu is the ideal choice for companies seeking high precision and prompt customer support.

Source: KEYENCE Website(https://www.keyence.com/products/measure-sys/cmm/xm/index_pr.jsp)

This CMM has a caliper-like feel, enabling even beginners to perform high-precision measurements. It can be carried without the need for temperature control, allowing for immediate measurements at any desired location and time. As it doesn't require a large installation space, it's a CMM with a low entry barrier.

Source: Carl Zeiss Website(https://www.zeiss.com/metrology/products/systems/cmm.html)

Utilizing linear drive on all axes, this CMM boasts high precision with a maximum permissible length measurement error of 0.3+L/1000μm, repeatability of ±0.2μm, and resolution of 0.001μm. The reduced occurrence of errors allows for a decrease in the need for remeasurement.

Source: Mitutoyo Website(https://www.mitutoyo.com/products/coordinate-measuring-machines/)

A CNC CMM that was first developed in 1976.

It features applications that respond to the demand for "Smart Factories" by allowing monitoring of operational status and maintenance management of the machine through the network.

Reasons for Selection