Coordinate Measuring Machines (CMMs) are essential tools in precision manufacturing, supporting quality assurance and high-accuracy inspections. Among the leading players in this space, Zeiss and Tokyo Seimitsu both offer robust solutions that serve advanced industrial needs. Rather than ranking one above the other, this article focuses on exploring their unique characteristics, specifications, and intended applications.

Zeiss is a global leader in metrology, known for delivering precision instruments used in sectors like aerospace, automotive, and healthcare. Zeiss CMMs are available in a variety of configurations including bridge, gantry, and horizontal-arm types. Their design emphasizes stability, repeatability, and adaptability across various inspection tasks.

One of Zeiss's key strengths is sensor flexibility. The company supports a modular system that enables switching between tactile, optical, and even X-ray (CT) sensors. This allows users to tailor the system for specific tasks, enhancing utility across multiple production lines.

The CALYPSO software is another highlight. It offers CAD integration, parametric inspection plans, and automated measurement strategies. Although the software requires training, it unlocks significant efficiencies once mastered.

Below is a summary of two representative models:

| Model | Measurement Range | Accuracy | Key Features |

|---|---|---|---|

| CONTURA | X: 700–1200 mm, Y: 700–2400 mm, Z: 600–1000 mm | 1.4 + L/350 µm | Bridge-type, multiple probe options, flexible software |

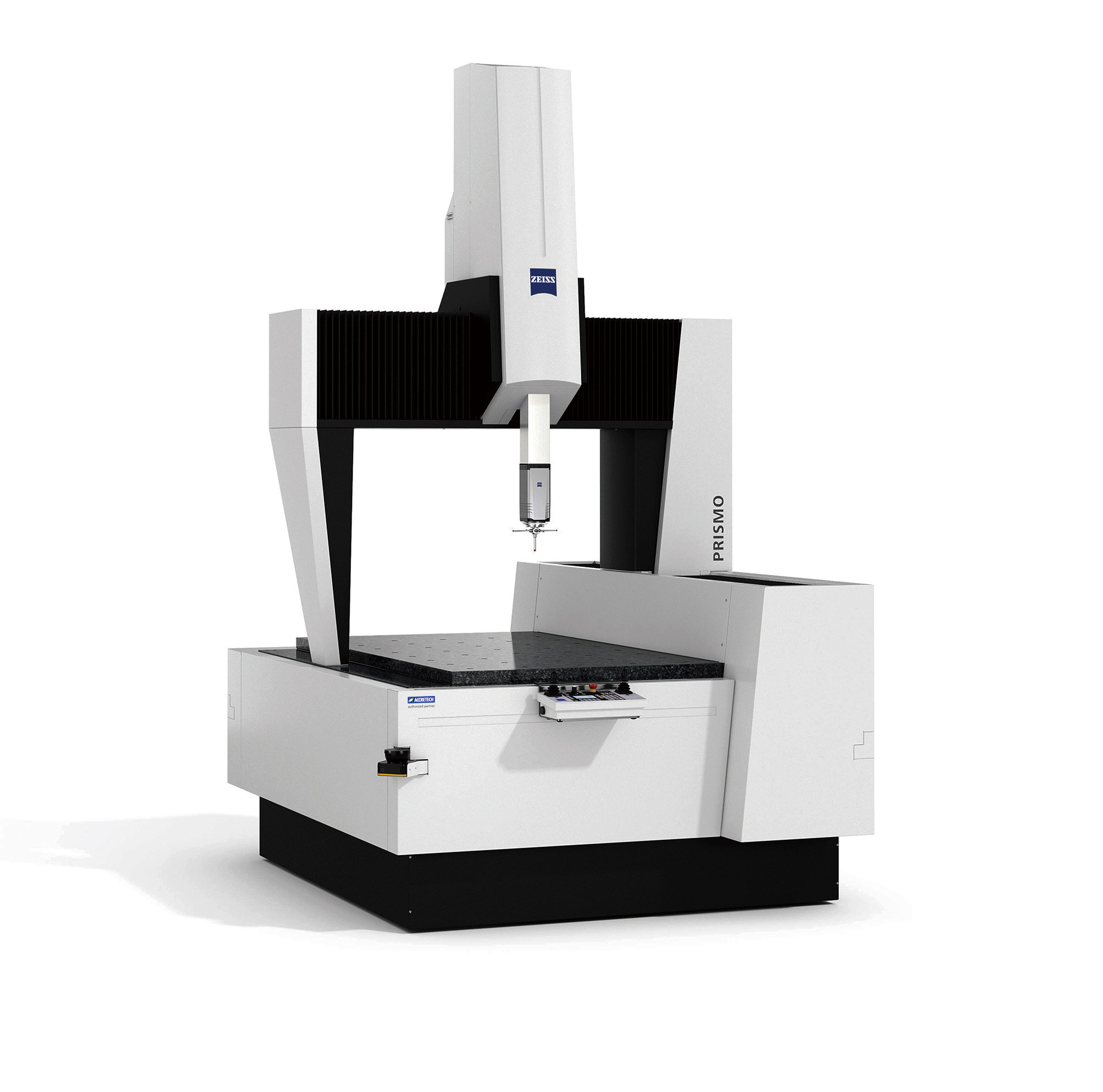

| PRISMO Ultra | Various configurations | 0.5 µm + L/500 | Ultra-high precision, air bearings, damped granite bed |

Tokyo Seimitsu, operating under the ACCRETECH brand, is known for its precision engineering in the measurement domain. In collaboration with Zeiss since 1995, Tokyo Seimitsu markets a range of co-developed CMM systems that combine Zeiss's optical expertise with Tokyo Seimitsu's precision hardware manufacturing.

These CMMs are engineered for accuracy and environmental stability. Many systems include air bearings, thermal compensation structures, and vibration isolation. Tokyo Seimitsu models also leverage Zeiss's CALYPSO software, ensuring high interoperability and advanced analytics.

Here are two representative models available through Tokyo Seimitsu and Zeiss:

| Model | Measurement Range | Accuracy | Special Features |

|---|---|---|---|

| ZEISS XENOS | 850 x 1200 x 1000 mm | ±0.3 μm | Ultra-high precision, advanced air bearings, active vibration isolation |

| ZEISS PRISMO | 700 mm to 3000 mm (configurable) | ±0.9 μm | High-speed scanning, multi-sensor compatibility, temperature compensation |

Both companies deliver top-tier CMM solutions, but there are nuanced differences in focus and application. Zeiss maintains global control over design, software, and sensor systems, ensuring standardization and a broader international support network. Tokyo Seimitsu, in contrast, customizes systems more toward Japanese industrial standards and offers enhanced support within the domestic market.

Tokyo Seimitsu models, while co-developed with Zeiss, often focus more on high-precision applications and include features fine-tuned for localized needs. Zeiss offers a more expansive portfolio including CT metrology and inline automation solutions.

Software-wise, both leverage CALYPSO, maintaining consistency in data processing and workflow management. However, Zeiss often supports newer software versions and broader plug-in ecosystems more quickly across global markets.

Zeiss is ideal for multinational corporations and R&D-heavy sectors requiring ultra-high precision and broad sensor options. Its global footprint ensures reliable support for operations across borders.

Tokyo Seimitsu is well-suited for manufacturers within Japan or East Asia who need localized support, Japanese-language documentation, and extremely tight tolerances in stable production environments. Their equipment is optimized for high-throughput, shop-floor integration with Japanese quality management systems.

Zeiss and Tokyo Seimitsu provide world-class metrology systems suited to a range of advanced inspection needs. While Zeiss emphasizes global scalability, sensor versatility, and high-end automation, Tokyo Seimitsu excels in locally optimized precision and tailored support. Choosing between them depends on your operational scale, geographic location, and specific technical requirements.