Coordinate Measuring Machines (CMMs) are critical instruments in dimensional inspection and quality assurance. Among the many manufacturers in this domain, Zeiss and Coord 3 represent two renowned names offering advanced solutions. This article outlines the major features, specifications, and typical applications of CMMs from both companies, focusing on their distinct strengths and areas of overlap rather than declaring one superior to the other.

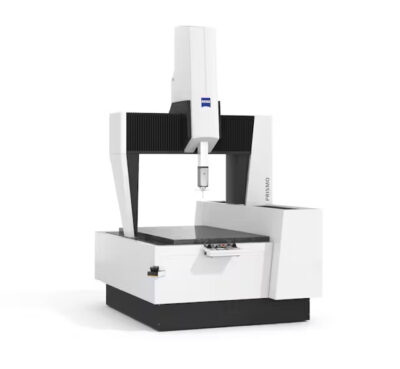

Zeiss is recognized globally for its precision metrology solutions. The company offers a comprehensive range of CMMs tailored to various industries such as aerospace, automotive, and medical manufacturing. Zeiss machines are built for reliability and high-resolution measurements, adhering to ISO 10360 standards. Their robust mechanical structure and advanced software provide consistent results in demanding environments.

A key strength of Zeiss lies in its flexible sensor systems, allowing users to switch between tactile probing, optical scanning, and even CT-based inspection, depending on part geometry and application needs. The systems are highly customizable to accommodate different sizes and inspection requirements.

Zeiss also offers CALYPSO software—a powerful suite that supports full CAD integration, automated inspection planning, and real-time data analysis. Though the software requires initial training, it delivers sophisticated error detection and comprehensive reporting capabilities once mastered.

Below is a summary of two representative models:

| Model | Measurement Range | Accuracy | Key Features |

|---|---|---|---|

| CONTURA | X: 700–1200 mm, Y: 700–2400 mm, Z: 600–1000 mm | 1.4 + L/350 µm | Bridge-type, multiple probe options, flexible software |

| PRISMO Ultra | Various configurations | 0.5 µm + L/500 | Ultra-high precision, air bearings, damped granite bed |

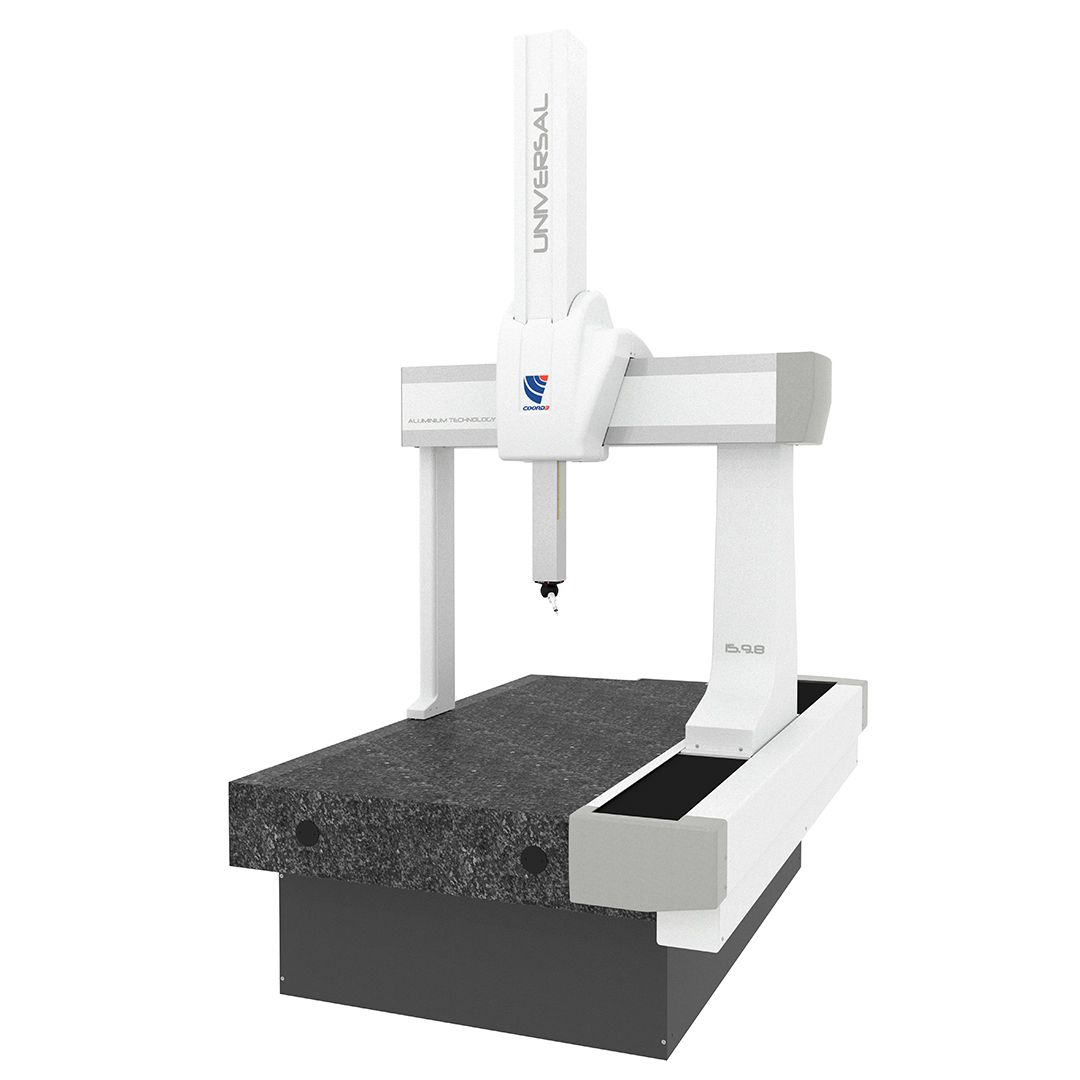

Coord 3, based in Italy, specializes in developing flexible and durable CMMs that cater to a wide range of industrial applications. Their offerings span compact entry-level machines to large-scale gantry systems. Known for mechanical strength and accuracy, Coord 3 systems are particularly suited for heavy-duty industrial inspection.

The machines are compatible with popular software solutions like PC-DMIS, allowing users to integrate them easily into existing quality workflows. Coord 3 also supports a variety of sensor technologies, including tactile and optical probes, giving users the ability to measure a wide array of part geometries with precision.

With high rigidity, thermal stability, and strong CAD compatibility, Coord 3 CMMs are a good match for manufacturers that require consistency, scalability, and the ability to automate measurement processes.

Typical specifications of Coord 3 models include:

| Model | Measurement Range | Accuracy | Key Features |

|---|---|---|---|

| Ares | 500x500x400mm to 2000x1500x1000mm | Up to ±2μm | High rigidity, expandability, multi-sensor support |

| MCT PLUS | 3000x2000x1500mm and above | ±2.5μm | Large-scale inspection, gantry structure, aerospace-ready |

Zeiss and Coord 3 both offer robust CMM solutions, but their primary differences lie in areas such as focus, flexibility, and system integration.

In terms of sensor technology, Zeiss supports a wider range of advanced options, including CT scanning. This allows for highly detailed internal and external measurements, especially useful in demanding industries. Coord 3 also offers multi-sensor capabilities, but places more emphasis on tactile and optical sensors, making it well-suited for standard industrial applications.

When it comes to software, Zeiss provides its own CALYPSO suite, a powerful and tightly integrated platform that handles everything from CAD data to automated reporting. Coord 3 typically works with third-party software like PC-DMIS. This approach gives users more flexibility in choosing a platform, though the level of integration can vary depending on the configuration.

The structural design of each system reflects its intended use. Zeiss machines prioritize ultra-precision through the use of granite bases and air bearings, resulting in high stability and minimal thermal expansion. Coord 3 systems, by contrast, are built for structural rigidity and scalability. They offer configurations that support the inspection of large components without compromising accuracy.

Both brands offer customizable options, but Zeiss may provide more seamless integration by leveraging its proprietary sensors and software. This can lead to a more unified system experience, especially for users already invested in Zeiss technologies.

Overall, Zeiss tends to serve high-end applications where maximum precision and full-system integration are critical. Coord 3, on the other hand, is a strong choice for companies looking for cost-effective, flexible CMM solutions that still deliver reliable performance in production environments.

Zeiss is ideal for organizations that demand the highest level of accuracy and traceability. Aerospace firms, research institutes, and manufacturers of precision components often rely on Zeiss systems. These users benefit from in-depth automation, cutting-edge sensors, and advanced software integration.

Coord 3 is well-suited for medium to large manufacturing facilities looking for durable, configurable, and cost-conscious metrology equipment. Its systems support both manual and semi-automated workflows, making them attractive to job shops and automotive suppliers aiming for balance between performance and investment.

Zeiss and Coord 3 bring complementary strengths to the CMM landscape. Zeiss emphasizes supreme precision, sensor variety, and integrated software, catering to the most exacting standards. Coord 3 focuses on versatility, affordability, and structural robustness, meeting practical inspection needs across a wide industrial base. Choosing between them depends on application demands, technical expertise, and organizational goals. By understanding their characteristics, users can make informed decisions that align with their measurement strategies and operational needs.