Coordinate Measuring Machines (CMMs) are essential for ensuring dimensional accuracy in manufacturing. Hexagon and FARO, two prominent CMM providers, cater to different operational needs. This article examines their key differences and commonalities—without favoring either—to help users make informed decisions based on their specific requirements.

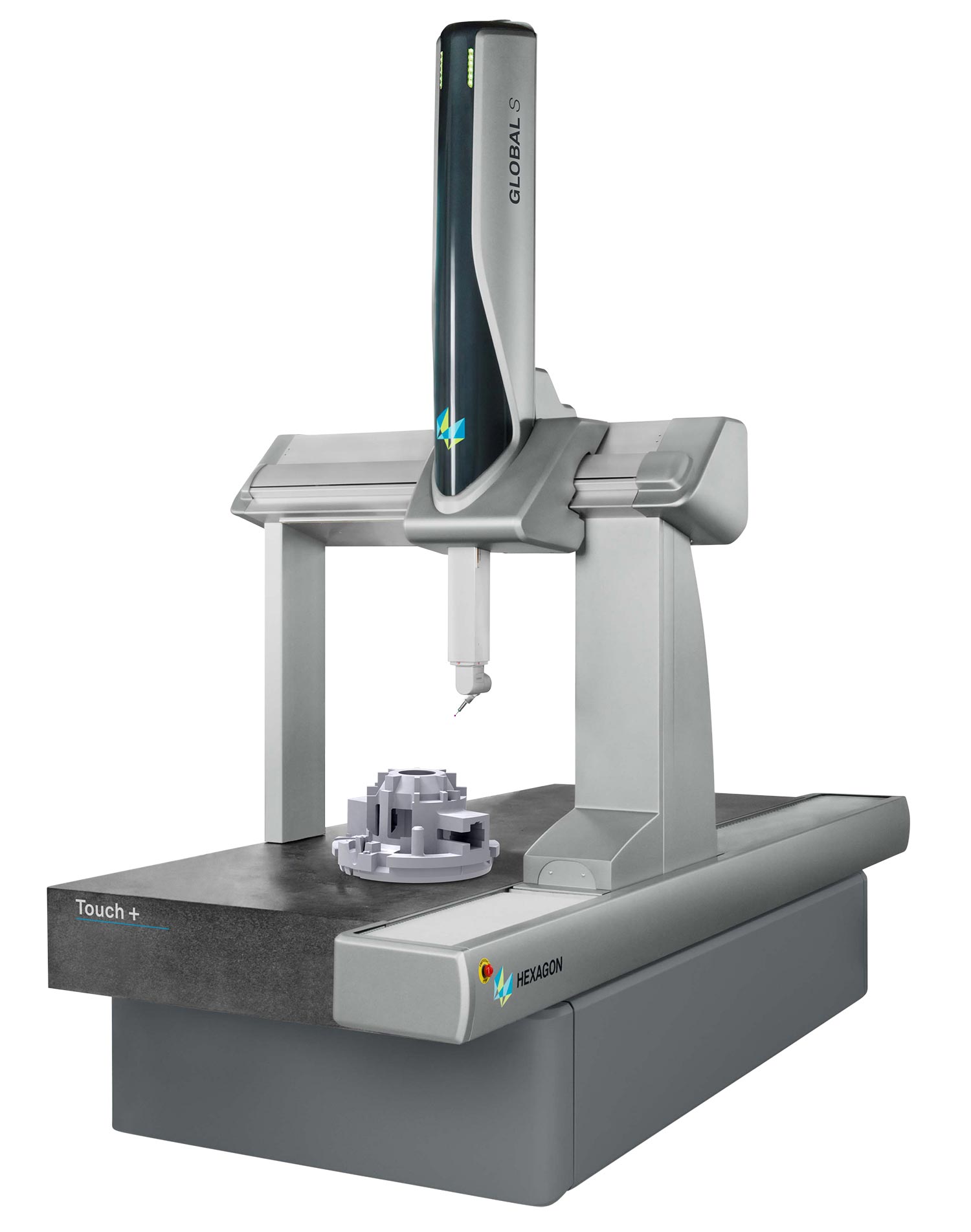

Hexagon is a globally recognized leader in high-performance metrology systems. Their CMMs come in bridge, gantry, and horizontal-arm configurations and support a wide range of tactile, laser, and optical sensors. Designed for automation and high-volume inspections, Hexagon machines are ideal for use in aerospace, automotive, and electronics manufacturing.

Hexagon’s hallmark PC-DMIS software allows for CAD-based inspection, automated routine execution, and real-time feedback. Models such as the GLOBAL Touch+ emphasize ease of use through touchscreen interfaces and streamlined workflows.

| Model | Measurement Range | Accuracy | Special Features |

|---|---|---|---|

| ALPHA | 1200 x 1500 x 1000 mm (varies) | ±1.5 μm | Bridge type, automation-ready, tactile sensor compatibility |

| GLOBAL Touch+ | Customizable | ±2 μm typical | Touchscreen UI, CAD integration, PC-DMIS |

FARO specializes in portable measurement devices, particularly articulated arm CMMs. Their systems are optimized for mobility, ease of use, and affordability—ideal for on-site inspections, alignment tasks, and reverse engineering. The FaroArm series offers fast setup, wireless operation, and high-precision tactile or laser-based measurement.

Software solutions like CAM2 and SCENE support real-time visualization, automated feature detection, and seamless CAD integration. Their systems are particularly popular in automotive repair, tooling, and additive manufacturing validation.

| Model | Measurement Range | Accuracy | Special Features |

|---|---|---|---|

| Gage Max | 1.2 m working volume | ±0.018 mm | 6-axis arm, portable, benchtop use |

| FARO ARM 8-Axis | Up to 4 m | ±0.029 mm | 8-axis rotation, wireless, reverse engineering tools |

While both Hexagon and FARO serve the coordinate measurement market, their approaches differ significantly in form factor, intended use, and integration. Hexagon provides fixed, high-precision CMMs suitable for controlled environments and automated processes. Their machines are built for repeatable inspections and integration into factory ecosystems, with strong PLM and quality software links. In contrast, FARO thrives in field-based, mobile applications where flexibility and rapid deployment are key.

Accuracy is one of the major differentiators. Hexagon's machines often deliver sub-micron precision and are capable of measuring large parts with very tight tolerances. FARO arms, while less precise, are sufficiently accurate for a wide range of industrial uses, especially when portability outweighs the need for absolute precision.

Sensor compatibility also varies. Hexagon supports multi-sensor setups, combining touch probes, vision systems, and lasers. FARO focuses on simplified, integrated designs optimized for single-user operation. The 8-axis configuration allows users to rotate the part during inspection, eliminating repositioning and improving productivity.

From a software perspective, PC-DMIS (Hexagon) and CAM2 (FARO) represent different philosophies. PC-DMIS is deep and complex, ideal for automated workflows and traceability. CAM2 is intuitive, fast to learn, and effective for real-time applications. FARO also emphasizes 3D visualization and digital twin applications more strongly.

In terms of infrastructure, Hexagon’s systems require more setup and environmental control but provide scalability for high-throughput, high-accuracy environments. FARO systems can be operated on a workbench or taken into the field—appealing to small- to medium-sized manufacturers or service providers.

Ultimately, Hexagon and FARO serve different yet occasionally overlapping user bases. Hexagon dominates high-end industrial inspection with fixed installations and sophisticated automation. FARO provides accessibility and mobility in a user-friendly package, enabling measurements to be taken wherever needed.

Hexagon is ideal for manufacturers seeking enterprise-level accuracy, automation, and integration. Industries such as aerospace, defense, and automotive benefit from its high-performance, scalable systems that support global standardization.

FARO suits users who value portability, ease of use, and rapid setup. It’s the preferred choice for tooling workshops, on-site maintenance teams, and those involved in prototyping or reverse engineering.

Hexagon and FARO represent two distinct philosophies in coordinate metrology. Whether you need a lab-grade, fixed-installation CMM or a mobile, flexible solution for field work, both brands deliver compelling value. Understanding your operational context—precision requirements, work volume, and inspection location—will determine which system is the better fit.