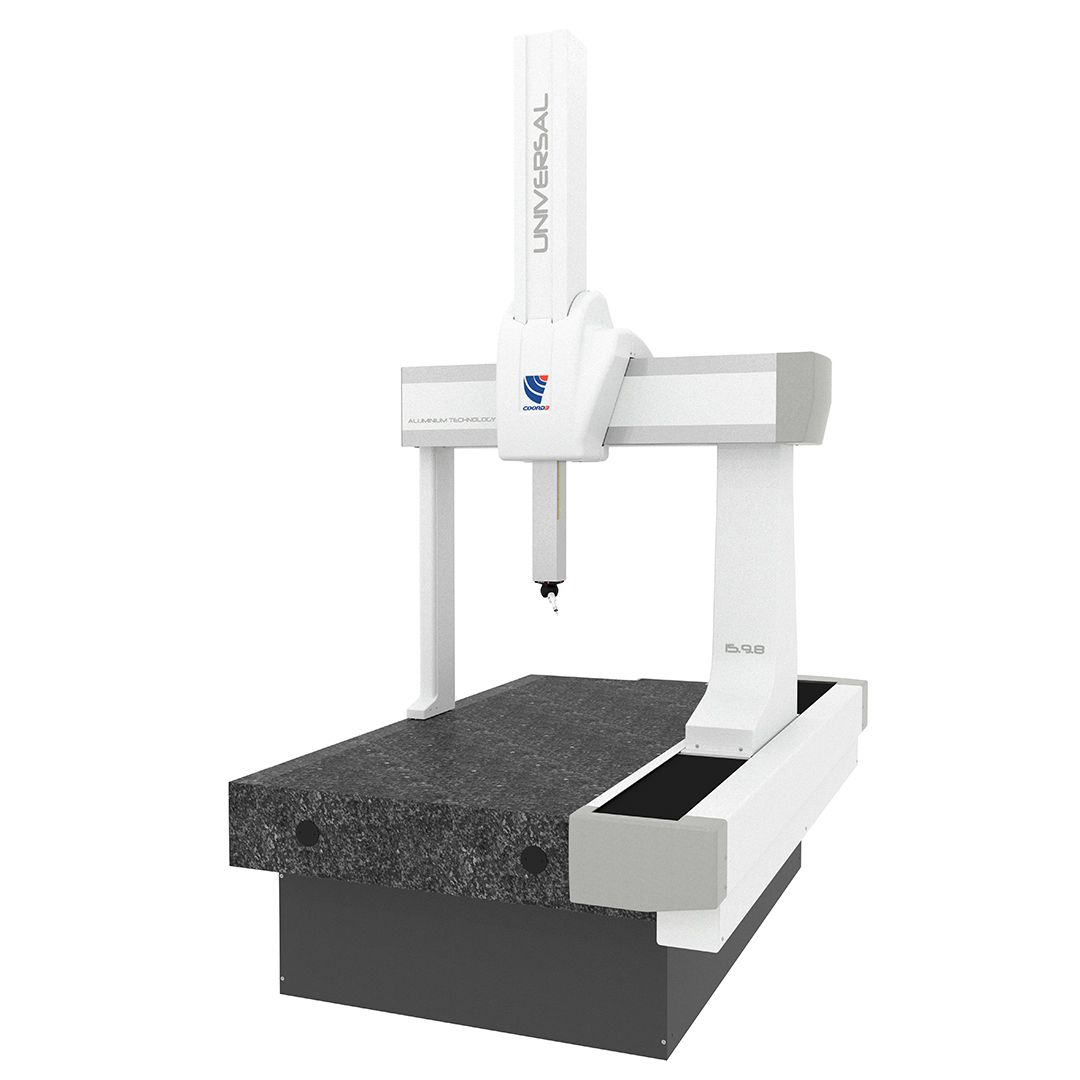

Introducing three major 3D measuring instruments from Coord3, highlighting their unique features, and a company profile that showcases its distinctive attributes.

Source: COORD 3

Source: COORD 3

(https://www.coord3.com/cmm-ares/)

The Ares is a bridge-type CMM designed for small to medium-sized parts, featuring an ultra-rigid alloy frame and pneumatically supported upright for high precision. It utilizes advanced technology with 0.1-micron resolution scales and supports both tactile and laser probes via TouchDMIS software. Available in manual or CNC configurations, it offers excellent cost-performance and consistent reliability. Operating optimally within an 18-22°C (64-72°F) temperature range, it includes a passive vibration damping system, making it ideal for automotive, aerospace, and manufacturing industries.

Source: COORD 3

Source: COORD 3

(https://www.coord3.com/cmm-mct-plus/)

The MCT Plus is a gantry-type CMM designed for large components, featuring a "Dual Drive" and "Dual Read" system to minimize deformation. It boasts stabilized steel X-beams and high-resolution 0.1µm linear transducers. The system includes a pinion/rack drive for X and Y axes for efficient movement of main axes and multi-sensor thermal expansion error compensation due to thermal expansion of structural components. Operating optimally within an 18-22°C (64-72°F) temperature range, this CMM is ideal for marine, aerospace, nuclear, and wind turbine industries.

Source: COORD 3

Source: COORD 3

(https://www.coord3.com/cmm-mct-plus/)

The Swan SI is a horizontal arm CMM featuring a lightweight aluminum mobile carriage, dual mechanical guides, and optical linear transducers. It includes DC servo motors and air bearings on X and Z axes, with precision guidance on the Y-axis to ensure high performance and precision. Designed for measuring thin-walled components, it operates best at 20 ± 2°C (68 ± 3.6°F) and handles vibrations up to 50 mm/sec², making it ideal for automotive applications.

Coord3 is an Italian manufacturer specializing in industrial metrology systems. Renowned for high-quality Coordinate Measuring Machines (CMMs), it offers over 35 models catering to various industries such as aerospace, automotive, and heavy machinery. Coord3 emphasizes innovation, flexibility, and quality, with their primary software called TouchDMIS. It features a 100% simple touch interface that includes the TouchCAD fast programming module. It also supports both tactile and laser scanning probes. Its CMMs provide precise, reliable measurements, enhancing quality control and efficiency in manufacturing processes.

COORD3 continues to engage in research and development of cutting-edge technology, resulting in the ability to provide customized solutions tailored to the specific needs of each customer. There are over 3,000 machines and measurement systems installed globally are designed to exceed customer expectations with high-quality standards.

Coord3 offers comprehensive after-sales services to maintain the value of customers' measurement systems. They provide timely responses through qualified technical staff. Services include TEAMVIEWER technical assistance, calibration per CMMA and UNI EN ISO 10360-2 standards, CMM retrofitting, preventive and corrective maintenance, machine relocations, off-line part programming, and measurement services. They also provide reverse engineering, GD&T consulting, advanced DMIS programming courses, and custom interface creation, all delivered directly or via their centers and laboratories. It should be noted that customer centers and services are primarily located in Italy.

Coord3's 3D measurement systems are well-suited for high-precision industries such as automotive, aerospace, marine, nuclear, and heavy machinery. They cater to companies requiring meticulous dimensional control and reverse engineering capabilities. Coord3 distinguishes itself with a range of over 35 CMM models, advanced TouchDMIS software, and a global support network, providing customized solutions to meet specific customer requirements.

Source: KEYENCE Website(https://www.keyence.com/products/measure-sys/cmm/xm/index_pr.jsp)

This CMM has a caliper-like feel, enabling even beginners to perform high-precision measurements. It can be carried without the need for temperature control, allowing for immediate measurements at any desired location and time. As it doesn't require a large installation space, it's a CMM with a low entry barrier.

Source: Carl Zeiss Website(https://www.zeiss.com/metrology/products/systems/cmm.html)

Utilizing linear drive on all axes, this CMM boasts high precision with a maximum permissible length measurement error of 0.3+L/1000μm, repeatability of ±0.2μm, and resolution of 0.001μm. The reduced occurrence of errors allows for a decrease in the need for remeasurement.

Source: Mitutoyo Website(https://www.mitutoyo.com/products/coordinate-measuring-machines/)

A CNC CMM that was first developed in 1976.

It features applications that respond to the demand for "Smart Factories" by allowing monitoring of operational status and maintenance management of the machine through the network.

Reasons for Selection