Presenting Hexagon's flagship CMMs, along with an overview of the company's distinctive characteristics and the research initiatives it has undertaken.

Source: Eley Metrology Ltd

Source: Eley Metrology Ltd

(https://www.lkmetrology.com/product-category/cmm/)

The LK Altera Series comprises versatile CMMs engineered for high precision and adaptability across diverse measurement tasks. Built with a robust structure, these machines deliver stability and accuracy even in demanding environments. Equipped with advanced probing systems including touch-trigger and scanning probes, the Altera Series enables detailed and precise measurements of complex geometries. Enhanced by user-friendly software, these CMMs optimize productivity and are well-suited for industries such as aerospace, automotive, and manufacturing.

Source: Eley Metrology Ltd

Source: Eley Metrology Ltd

(https://www.lkmetrology.com/product-category/cmm/large-volume-cmm/)

The AEROS Series showcases an innovative mechanical design crafted to guarantee long-term metrological performance and stable measurement data, thereby minimizing maintenance and calibration expenses. It features an aluminum alloy Z-axis spindle, a "Single Read" scale system on the X-axis, and a lightweight Y-axis cross-beam to maximize rigidity. The multi-sensor system effectively compensates for thermal expansion errors, while optional "Dual Read" scales on X-axis beams and high-resolution optical scales further enhance performance. Protective covers and bellows for the X and Y axes are also available.

Source: Eley Metrology Ltd

Source: Eley Metrology Ltd

(https://www.lkmetrology.com/product-category/cmm/large-volume-cmm/)

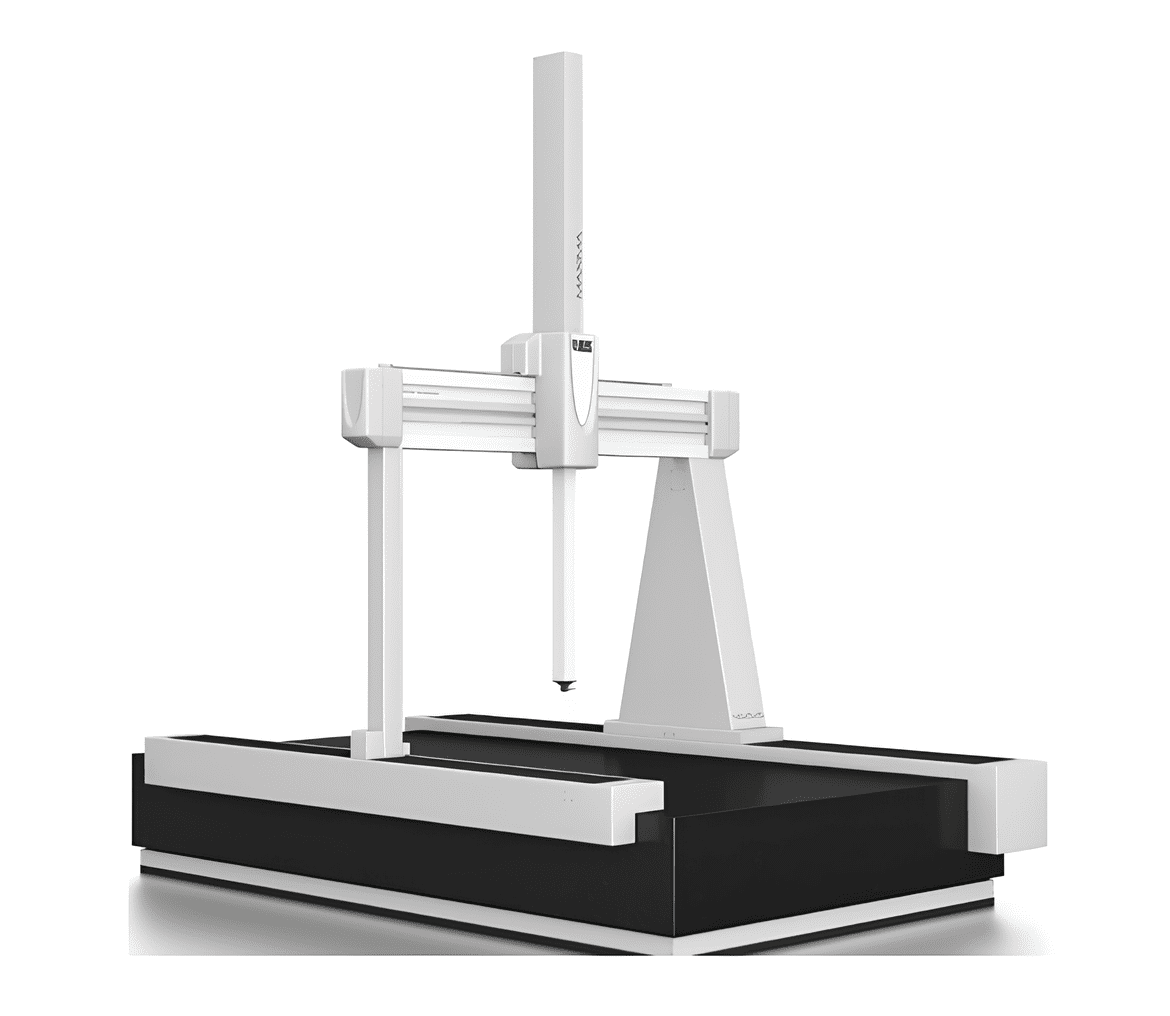

The LK Metrology Maxima stands as a large bridge CMM meticulously designed for high accuracy and reliability, leveraging bonded ceramic materials to ensure stiffness and resistance to wear and temperature variations. Available in three variants—a standard work-table, a twin runway design, and a single raised shoulder version—the Maxima facilitates easy loading of long components. Equipped with support for various probing solutions, including touch-trigger, contact scanning, and non-contact laser scanning, it caters to industries such as aerospace, large-scale commercial vehicles, and manufacturers of large performance-critical components.

LK Metrology is a distinguished company specializing in the design, manufacture, and support of high-precision coordinate measuring machines (CMMs) and comprehensive metrology solutions. Founded in 1963, the company has earned a reputation for providing innovative and reliable measurement technology to a variety of industries, including aerospace, automotive, and manufacturing. The following are some of LK Metrology's key features:

LK Metrology is renowned for its continuous investment in research and development, leading to the creation of advanced measurement solutions. The company’s CMMs are equipped with state-of-the-art probing systems, sensors, and software that ensure high accuracy and reliability.

With a robust global presence, LK Metrology operates multiple facilities and support centers worldwide. This extensive network allows the company to offer exceptional customer service and technical support, ensuring that customers receive prompt and efficient assistance. The global reach of LK Metrology ensures that customers have access to the latest technologies and expert support, enhancing their overall experience and satisfaction.

LK Metrology provides a diverse range of CMMs and metrology solutions tailored to meet various measurement needs. From portable measurement arms to large-scale CMMs, their product portfolio addresses a wide array of industry requirements. The availability of customizable options enables customers to tailor solutions to their specific applications, ensuring precision and efficiency in their measurement processes. These features underscore LK Metrology's commitment to delivering high-quality, innovative, and globally supported measurement solutions.

Customers seeking LK Metrology's CMMs demand high precision, reliability, and advanced measurement capabilities. Ideal industries include aerospace, automotive, medical devices, and large-scale manufacturing. These customers require consistent performance, the capacity to handle complex geometries, and long-term stability with minimal maintenance. Their operations often necessitate stringent quality control and compliance with regulatory standards.

Source: KEYENCE Website(https://www.keyence.com/products/measure-sys/cmm/xm/index_pr.jsp)

This CMM has a caliper-like feel, enabling even beginners to perform high-precision measurements. It can be carried without the need for temperature control, allowing for immediate measurements at any desired location and time. As it doesn't require a large installation space, it's a CMM with a low entry barrier.

Source: Carl Zeiss Website(https://www.zeiss.com/metrology/products/systems/cmm.html)

Utilizing linear drive on all axes, this CMM boasts high precision with a maximum permissible length measurement error of 0.3+L/1000μm, repeatability of ±0.2μm, and resolution of 0.001μm. The reduced occurrence of errors allows for a decrease in the need for remeasurement.

Source: Mitutoyo Website(https://www.mitutoyo.com/products/coordinate-measuring-machines/)

A CNC CMM that was first developed in 1976.

It features applications that respond to the demand for "Smart Factories" by allowing monitoring of operational status and maintenance management of the machine through the network.

Reasons for Selection